Implementation of a BCS®

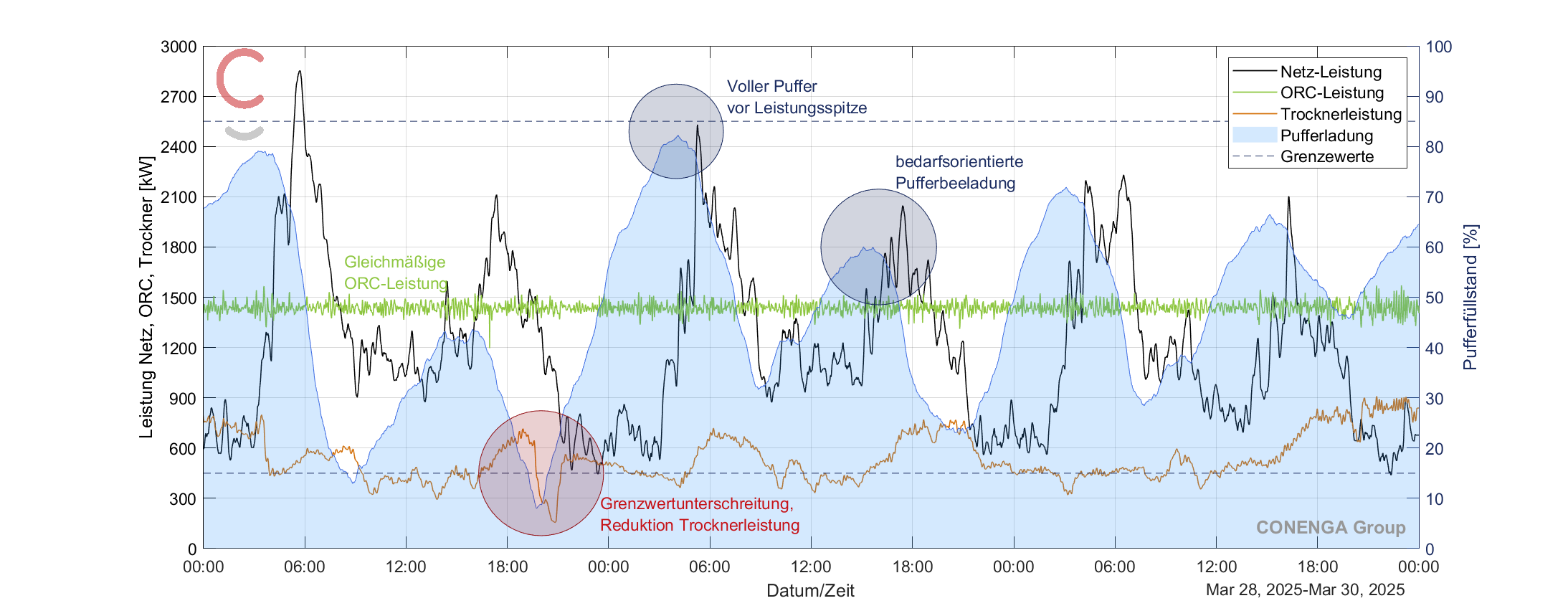

firing rate control (FLR) and a BCS® buffer storage management (PSM) including the control of all water-side units

The challenge

- Oscillating and unstable operation of the system at high output

- Frequent system failures

- Constant manual intervention is necessary, especially in winter

- Overall low ORC utilization

- No automatic load specification for the heat generators

- Operator must set suitable operating mode himself and adapt it daily to the conditions in the district heating network

Objective

- Uniform boiler output and avoidance of load drops.

- Increased automation with reduced manual intervention.

- Optimization of fuel flexibility and stabilization of steam management.

- Compliance with emission limits for CO and NOx.

- Increased efficiency by reducing gas consumption, caking and cleaning downtimes.

Implementation

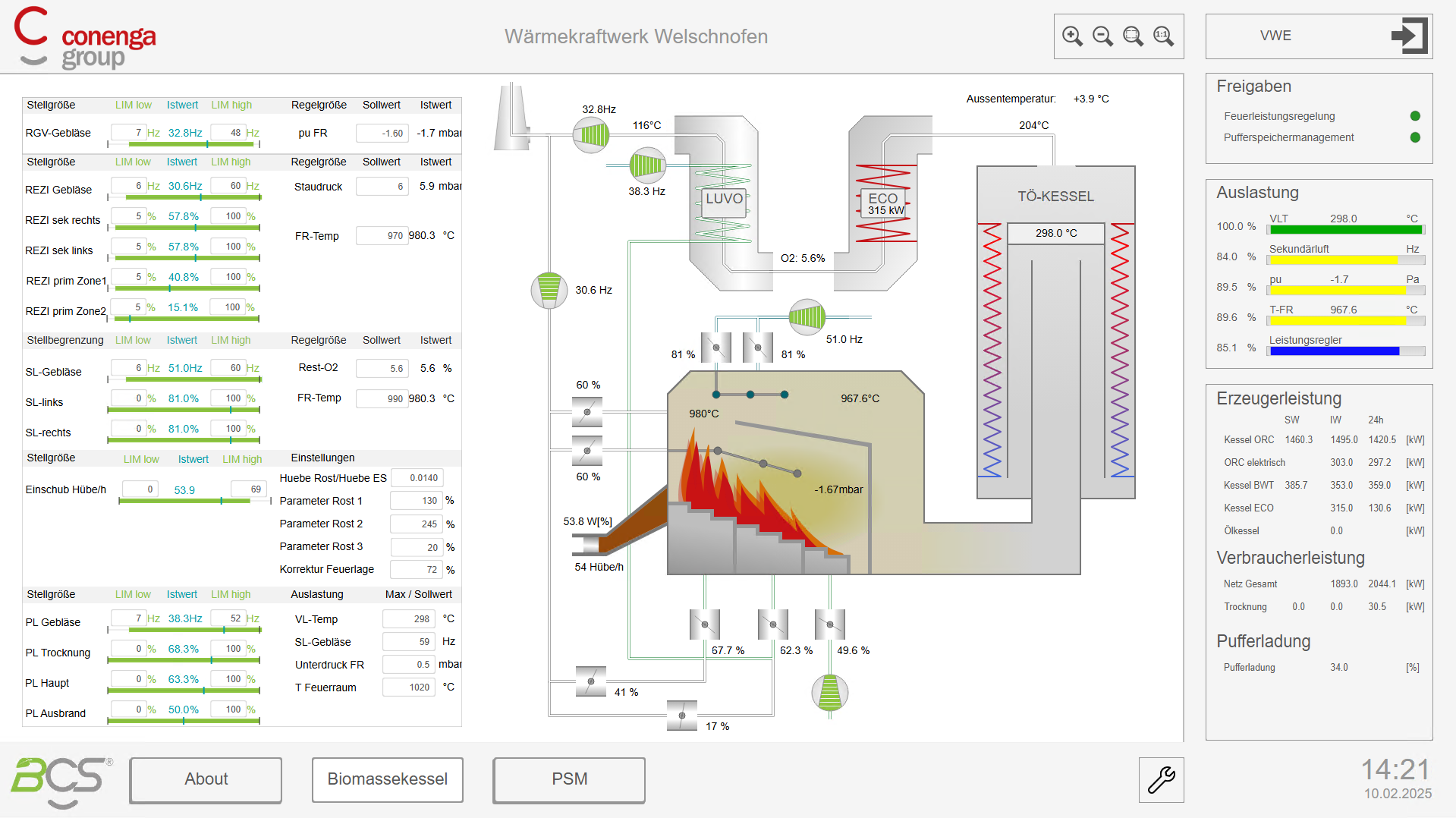

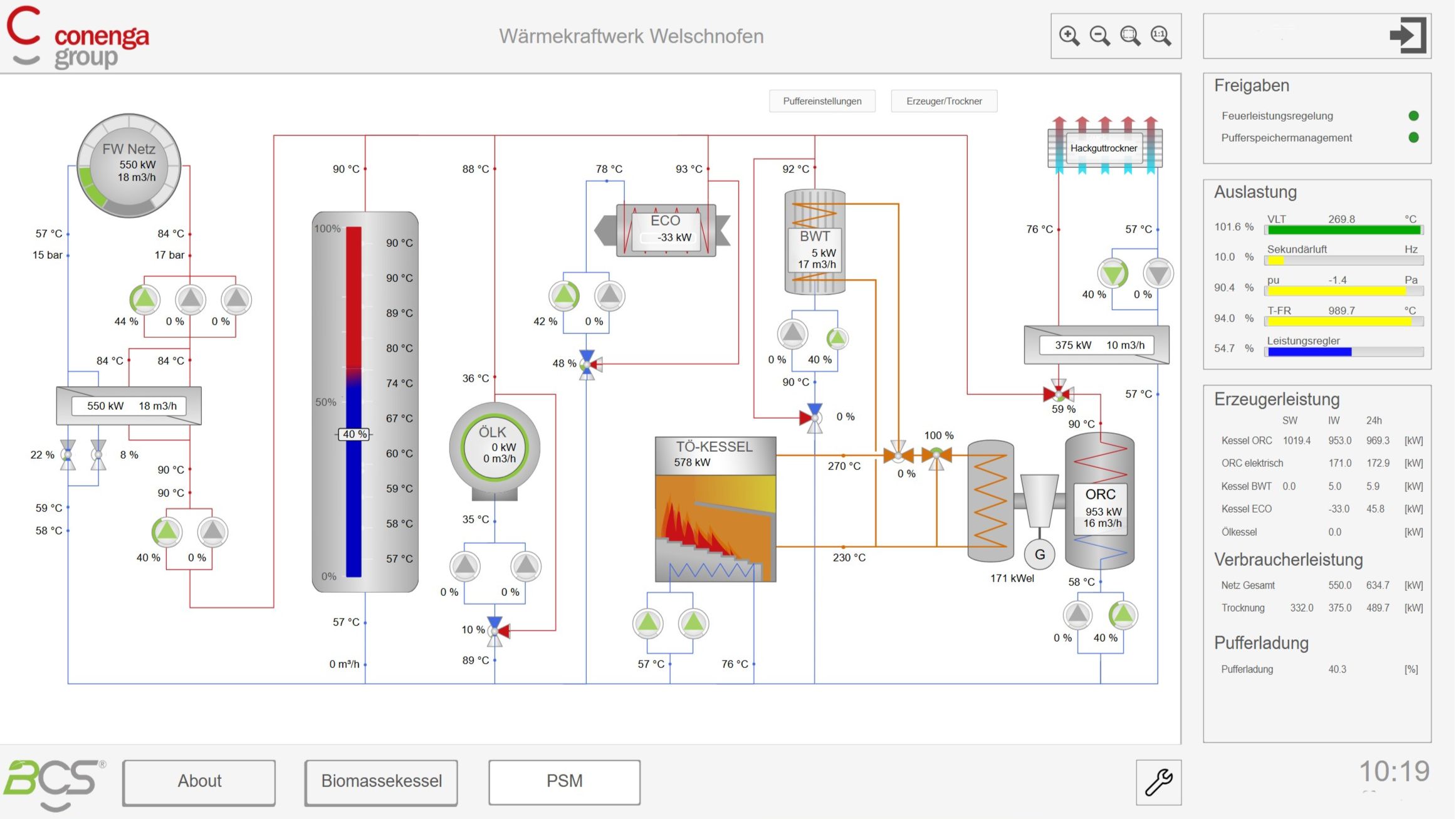

- Signal switching with Modbus TCP, connection with Siemens T3000. Technical specifications from us, programmer from Siemens

- FLR module: Quantity control of flue gas quantities, use of water content calculation for fire position correction and rezi quantities in the primary zone

- PSM/LHM module: Thermal oil boiler with ORC module and operating heat exchanger, economizer, fuel drying as controllable heat sink Control of all relevant water-side units including pump changeovers

Results

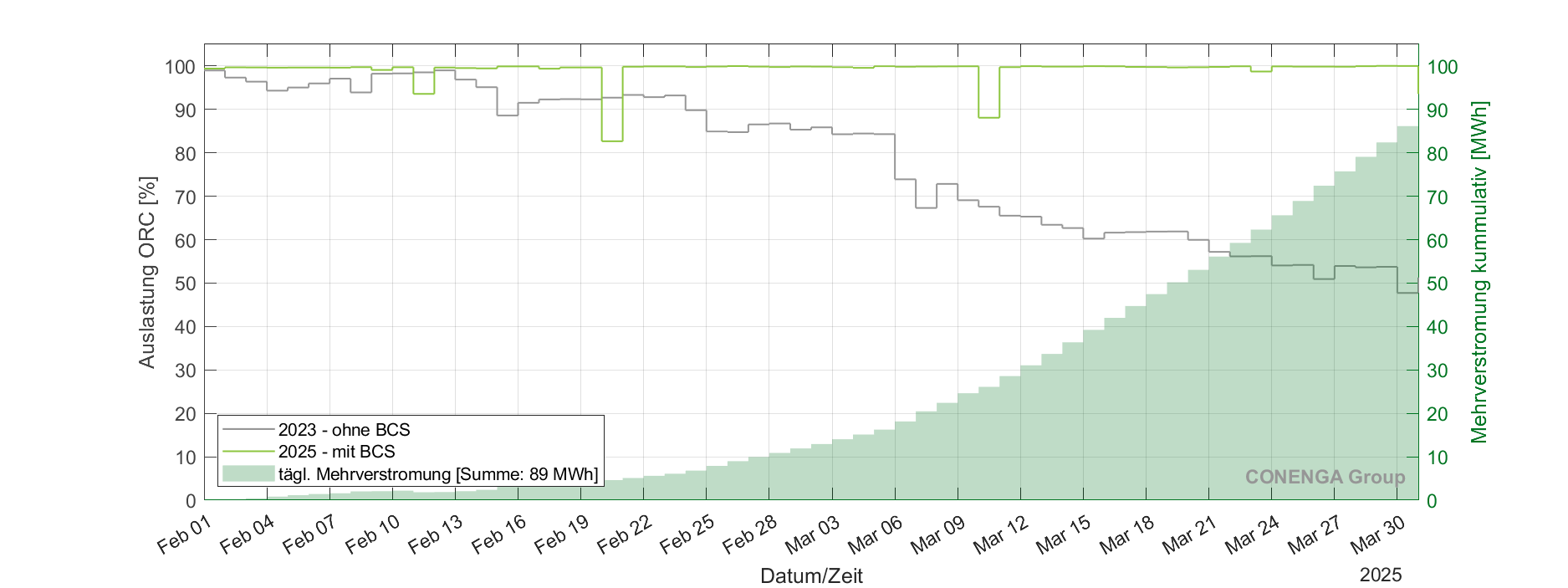

- Increase in the ORC turbine’s power generation efficiency from approx. 93% to >99

- Additional yield from ORC power generation > € 50.000,-/a

- Automatic and trouble-free operation of the entire system in various load ranges

- Reduction in manual interventions from >20 h/week to < 1 h/week

- Combustion homogenization with constant target values in the furnace

- Continuous full-load operation of the entire system at the performance limit

- Automatic load specification to the boiler

- Compliance with buffer loading limits

- Fully automatic operation of the entire system, even with changing power consumption in the grid

- Consistent utilization of the ORC system

- Compensation of required load changes through controllable fuel drying