BCS® Suite

BCS® Suite

Precisely fitting. Performance-enhancing. Safe. Sustainable.

The BCS® (Biomass Control Solution) Suite is a superordinate regulation for biomass heating (power) plants and improves them in several areas. It consists of six standardized modules that can be individually combined depending on the system configuration. In the BCS® Suite, we combine process engineering know-how with modern control technology and digitalisation to create a compact, quickly deployable product.

You benefit from the improvement in overall efficiency and the consistently efficient operation of your biomass heating (power) plant. Less fuel is used and less work is required due to a significant reduction in the necessary manual interventions, which is economically significant. Optimizing your biomass heating (power) plant with a BCS® also makes a considerable contribution to climate protection by significantly reducing emissions. The service life of your system is also extended thanks to constant, even operation of the boiler.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail? On our contact form you will find various ways to get in touch with us:

I am looking forward to answering your questions!

David Hechinger is our expert for your BCS® Suite!

BCS® – Biomass Control Solution

Based on the potential study, we select the right combination of preconfigured BCS® modules for your specific system configuration. We then adapt the BCS® Suite to your requirements in order to optimally exploit the improvement potential identified for your plant.

The BCS® Suite increases performance with innovative control concepts that are optimally designed for the processes in heating (power) plant operation. The BCS® handles different system controls in the inventory as a superordinate control and convinces with complete cloud connection. Integration into the existing environment takes place seamlessly during operation, without downtimes and without intervention in the existing safety chain.

The BCS® Suite follows a superordinate control strategy that presets setpoints on existing control loops. This ensures that the existing plants integrated into the BCS® continue to be operated within the process engineering limits and corresponding safety concepts specified by the plant manufacturer. The existing safety concept remains fully in place and is not affected or restricted in any way by the overriding regulation.

Thanks to improved overall efficiency and a significant reduction in fuel consumption and own power consumption, the use of the BCS® Suite also improves the sustainability of your plant in step with the increase in economic efficiency. This also leads to a reduction in emissions. The BCS® Cloud also enables precise reporting to reduce yourcarbon footprint and thus makes a valuable contribution to sustainability reporting.

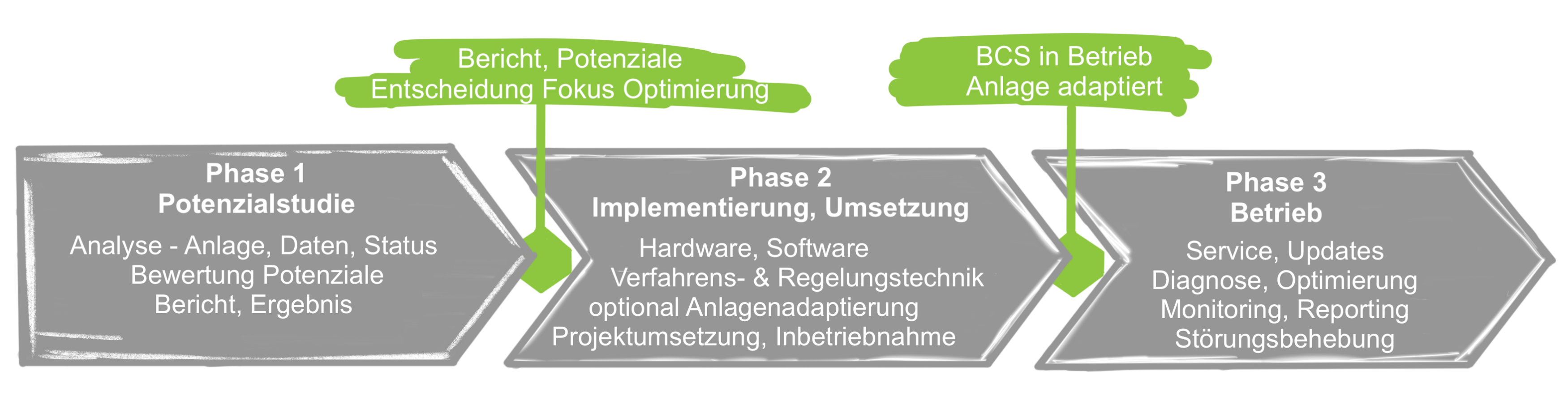

BCS® project procedure

In principle, it is possible to implement a BCS® project as an investment or via a user agreement. In both cases, the implementation conforms to the EU taxonomy. The contributions corresponding to the environmental objectives (taxonomy, Article 9) are presented.

We design your BCS® project together in three phases.

In the potential study, we analyze your biomass heating (power) plant and derive process and control technology improvement potentials that can be exploited by adapting the system and implementing the BCS® Suite. The potential study includes a well-founded analysis of available operating data with suitable tools for data analysis, an on-site inspection of the plant for the purpose of identifying the plant condition, and an intensive exchange with the operating team. We link the insights gained in this process with the results from the data analysis and derive the optimization potentials as a whole. Furthermore, we develop variants for the implementation of the optimization as a basis for decision-making for the following phase of implementation.

Depending on the type of optimization you have decided on, the engineering for the plant adaptation (process engineering), the development of the control concept, the customizing of the control system and the implementation on site are carried out. We adapt your system in coordination with downtimes, supplement or renew sensor technology, create the prerequisites for the BCS® Suite (hardware: PLC, server, network connection; software) and commission the new higher-level control system with signal switching (cold and warm commissioning). The existing safety concepts remain fully functional. The operating staff is fully trained and the implementation project is completed.

The commissioning is immediately followed by an operation that is intensively accompanied by us via secure remote maintenance in order to round off the optimization, taking into account the various operating states. The BCS® Service comprises several services in stages, such as the periodic automation check, license maintenance, software updates and process and control engineering support in the event of unexpected operating states. In many cases, this is also rounded off with complementary service packages for ongoing optimization and sound interpretation of available data. Based on evaluations, we support the adaptation of your parameterization, carry out changes and advise you if necessary. This ensures secure and high-performance operation over the entire life cycle of the BCS®. Find out more about service here.

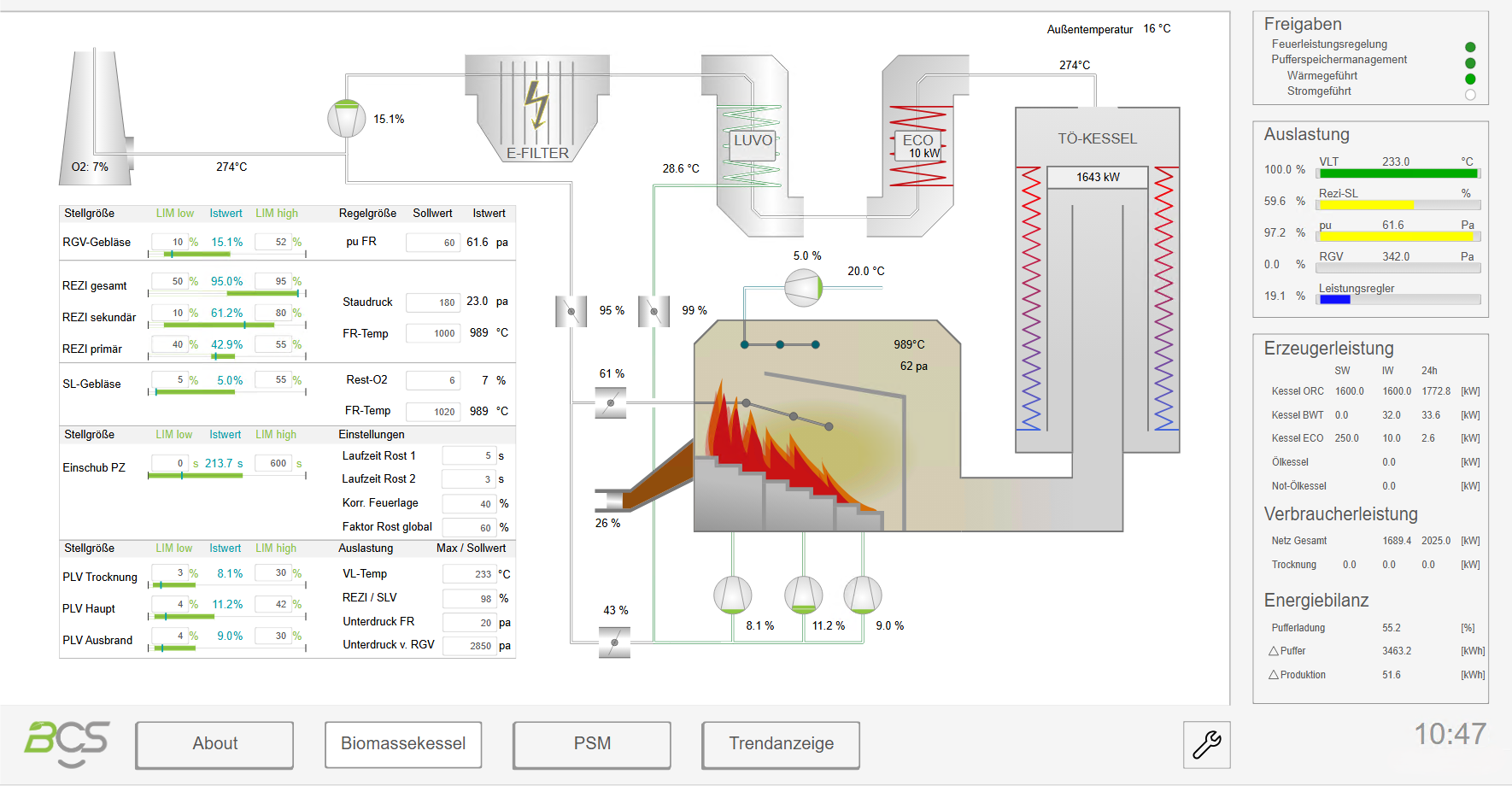

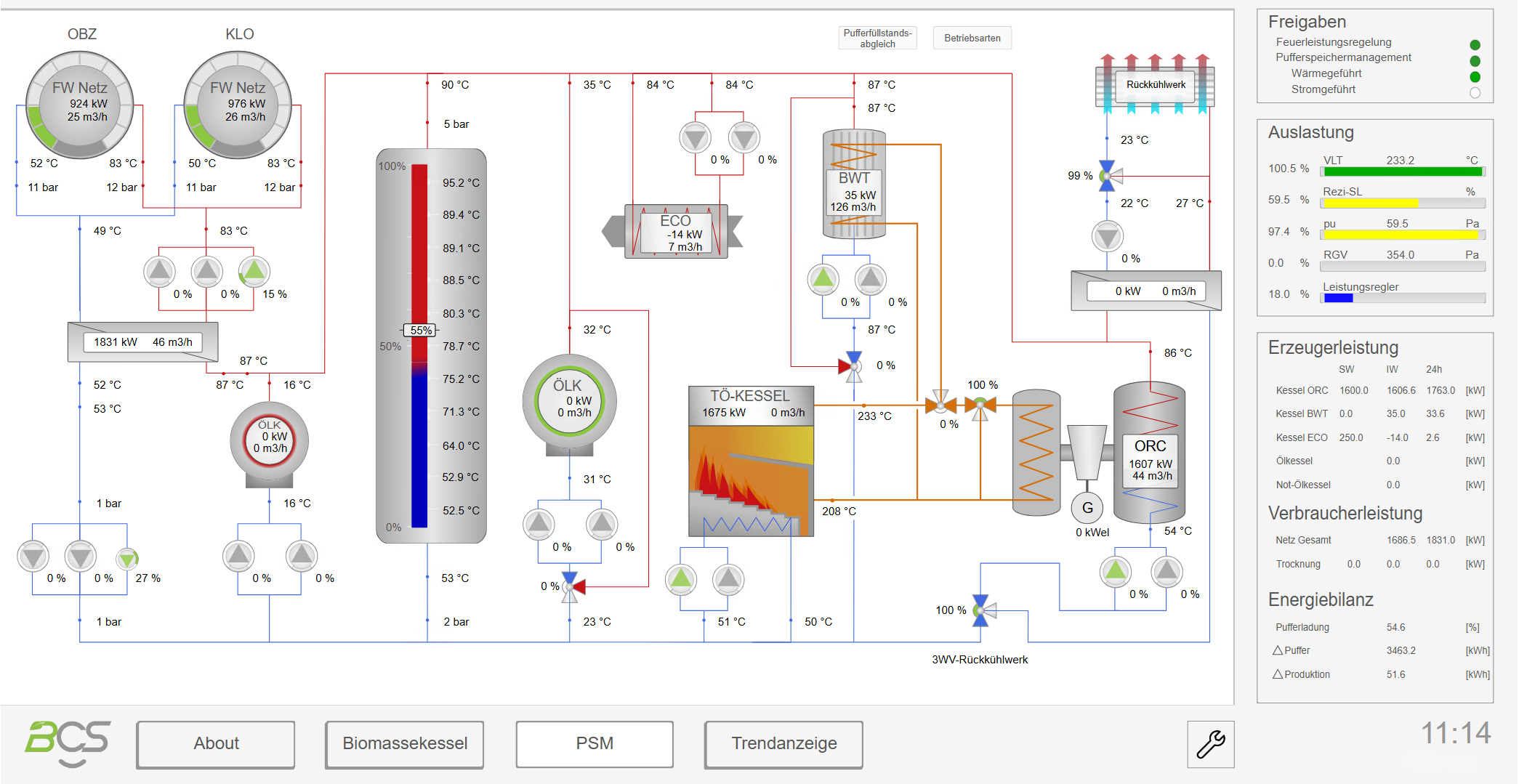

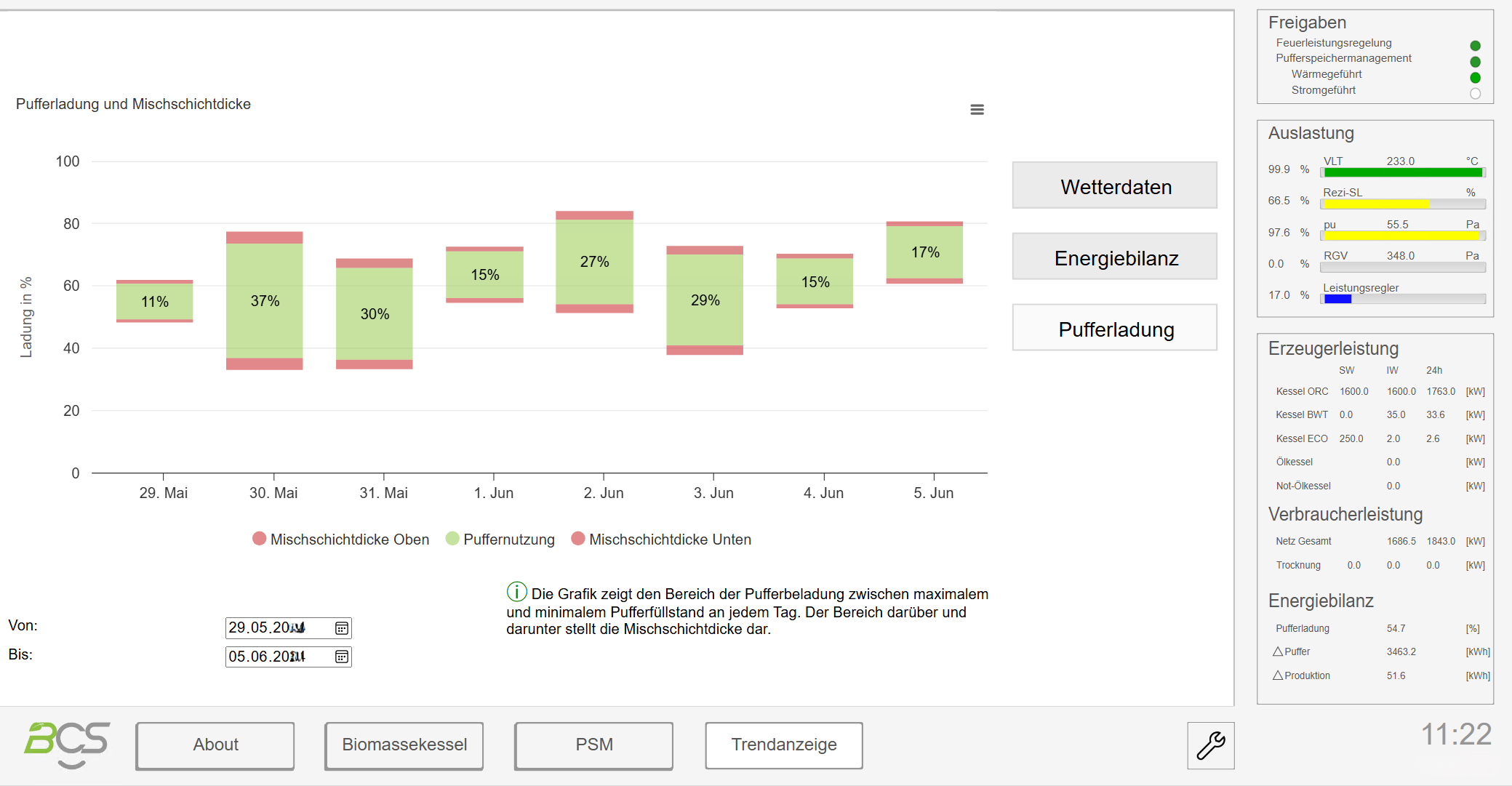

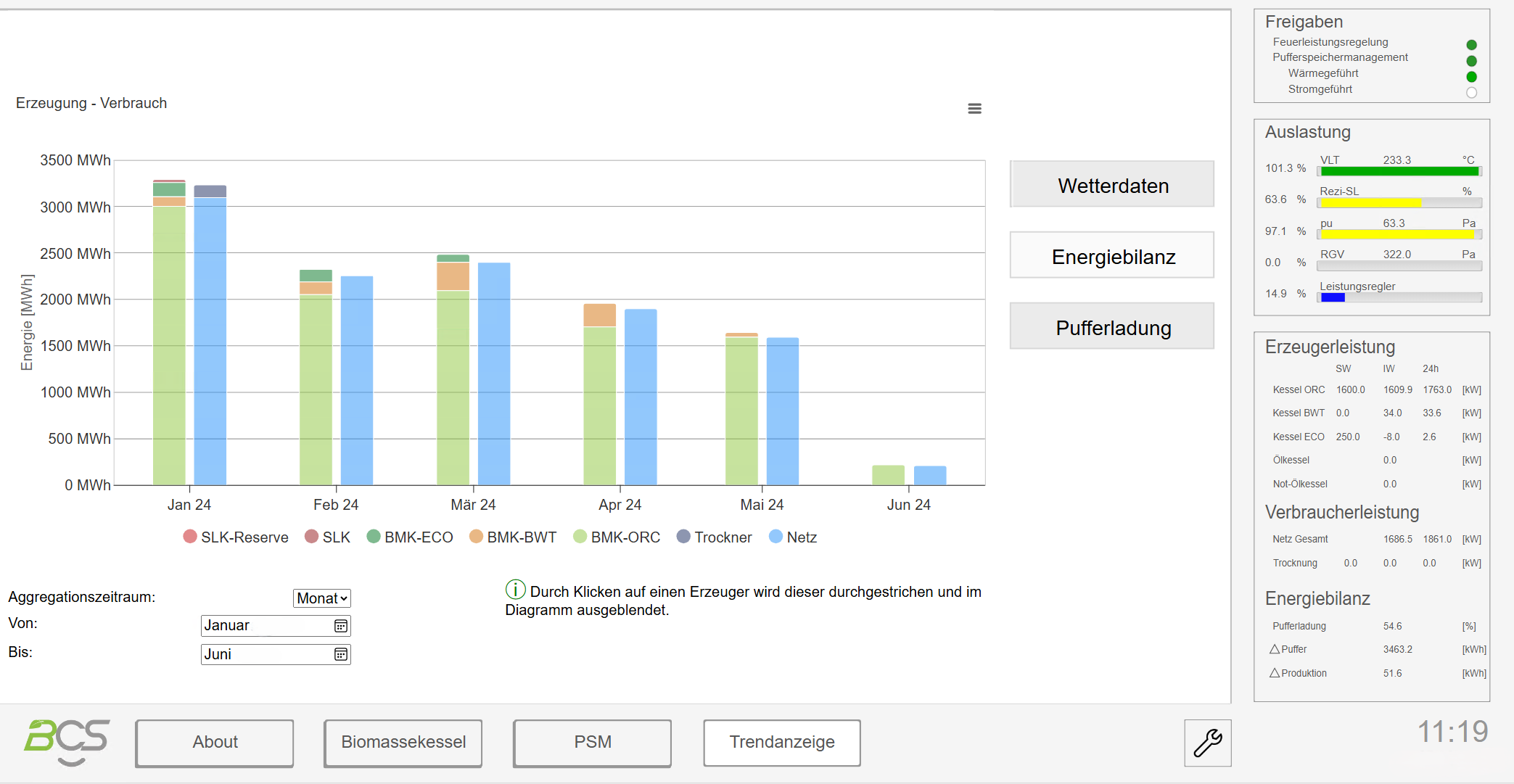

BCS®-HMI

Our modern, intuitive & user-friendly HMI clearly displays all important data and information. This allows you to maintain an overview at all times.

A wide variety of evaluations and forecasts can be customized to your requirements and needs.