Fire power control

Fire power control

Our firing rate controls enable optimized operation of combustion processes in firing systems, maximizing performance and efficiency. Through real-time monitoring and adaptability to changing operating conditions, our solutions achieve continuous optimization of system performance.

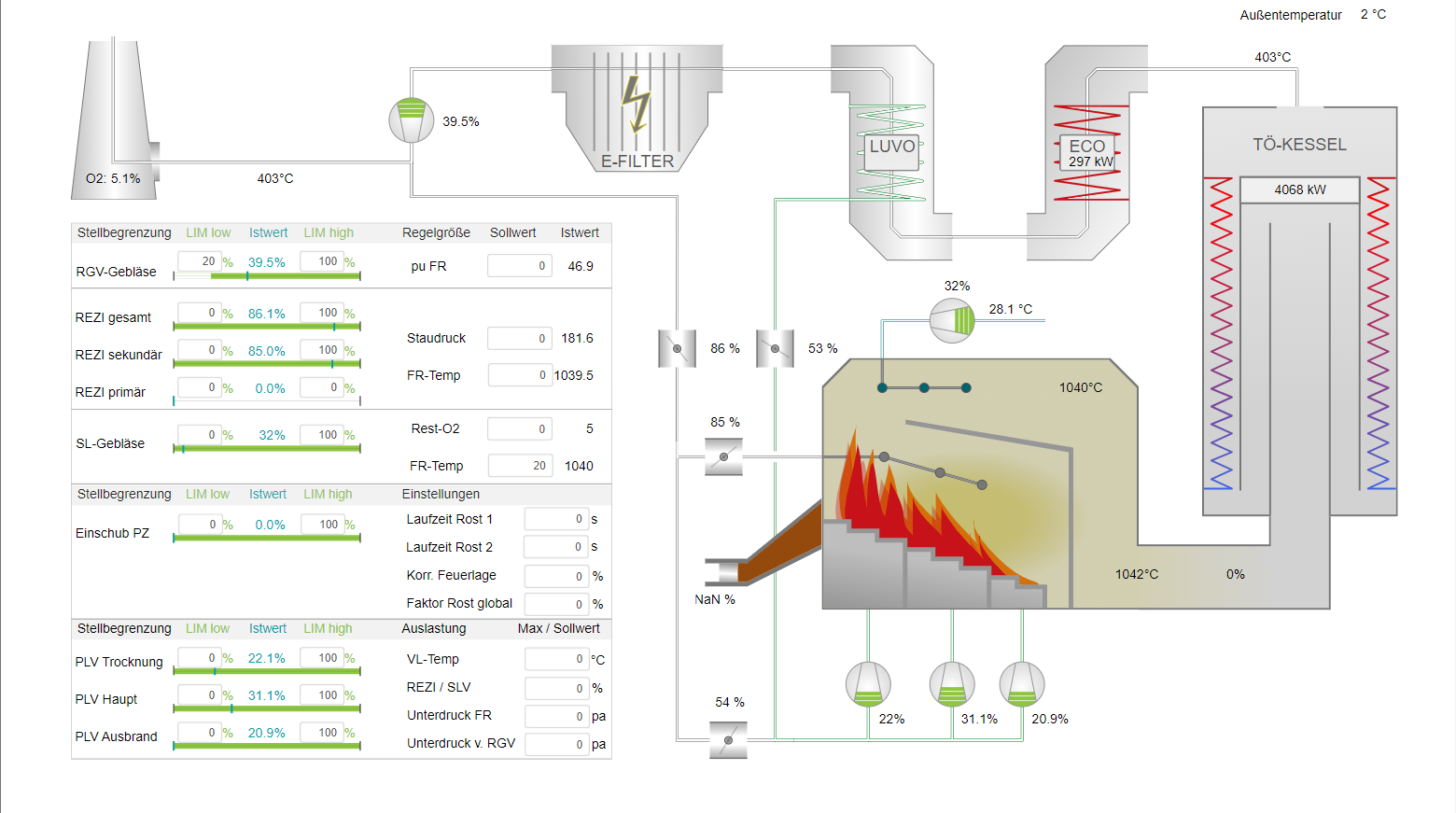

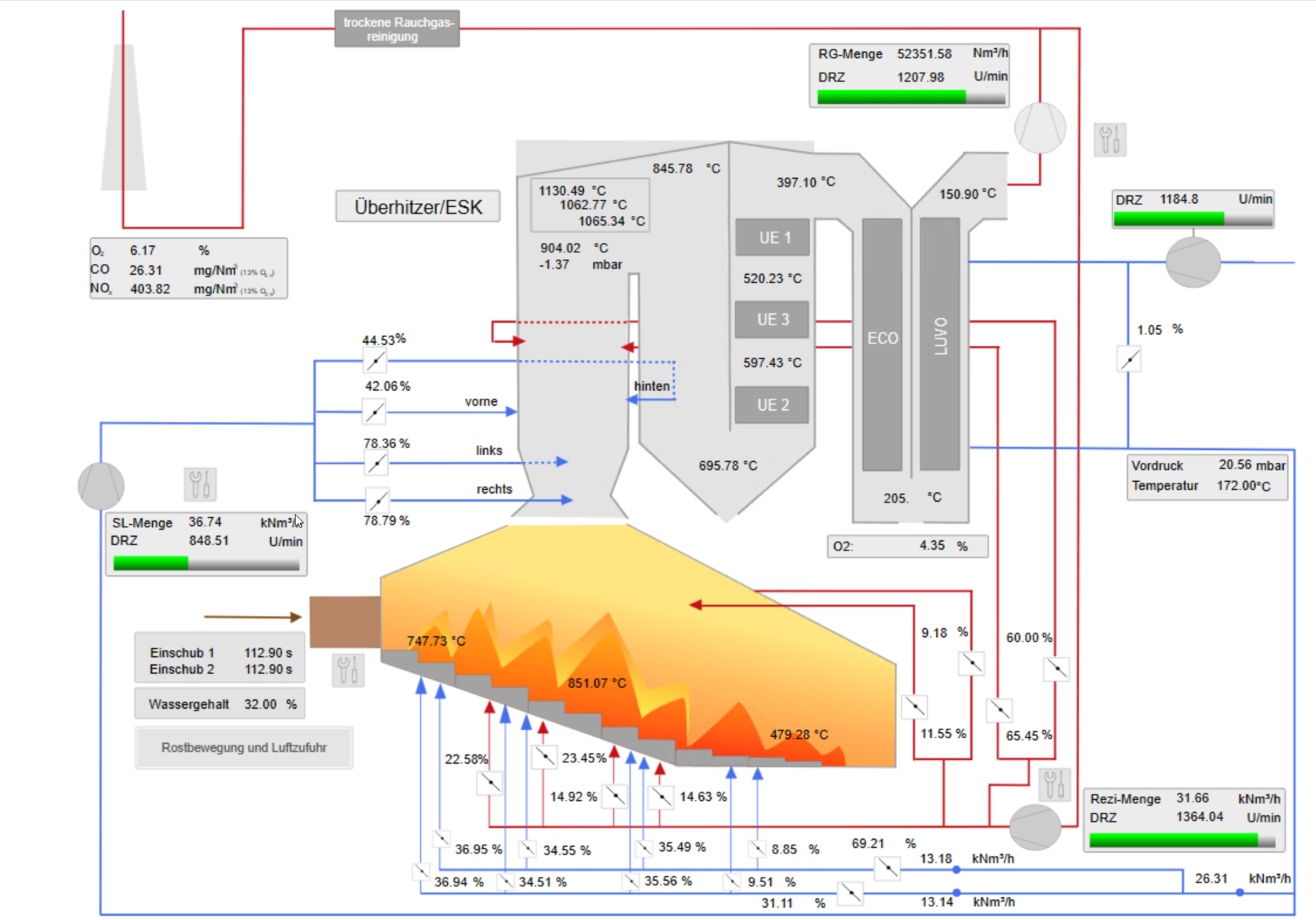

Our core products EPOC® Suite and BCS® Suite already contain predefined controllers, function modules and standards that reflect many years of experience with a wide variety of firing systems and the corresponding control concepts.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Sebastian Sturm is your expert when it comes to fire power control!

The advantages of our fire performance regulations include:

Precise combustion control:

Our systems enable precise control of fuel supply, air supply and other parameters to ensure efficient combustion and maximum output. This enables industrial companies and energy producers to reduce fuel costs and improve operating efficiency.

Emissions reduction:

Our firing rate controls are designed to monitor and minimize emission levels. Optimized combustion minimizes emissions such as nitrogen oxides (NOx), carbon monoxide (CO) and dust and fly ash content, which helps to comply with strict environmental regulations.

Cost savings:

Our control systems maximize the utilization of the fuel used by efficiently controlling the combustion process and minimizing fuel consumption. This leads to a reduction in operating costs and contributes to the company’s profitability. Optimizing fuel consumption leads to direct cost savings. Lower thermal loads and reduced wear reduce maintenance effort and costs.

Reliability and durability:

Our solutions are characterized by their robustness and durability, which ensures long-term investment security and minimizes downtimes. The systems can work reliably even under demanding operating conditions, which increases productivity and reduces the risk of unexpected downtime. Our customized firing capacity reduces the thermal load on the boiler components, which leads to a longer service life of the system. By avoiding unnecessary load changes and overheating , component wearis reduced.

Security:

Precise control of the fire output ensures stable operating conditions, which increases the safety of the system.

Flexibility:

Our firing rate controls are flexible and can be adapted to the specific requirements of different industrial applications and power generation scenarios. We offer customized solutions that are tailored to the individual needs and requirements of our customers. Our control system enables the boiler to react quickly to changes in heat demand, which is particularly important in applications with highly fluctuating energy requirements. Our firing rate control can be set to burn different fuels optimally, which increases the flexibility of the system.

Our firing rate controls are versatile and can be used in various types of boilers and firing systems to optimize performance and efficiency.

Types of firing for which our firing rate controls can be used successfully:

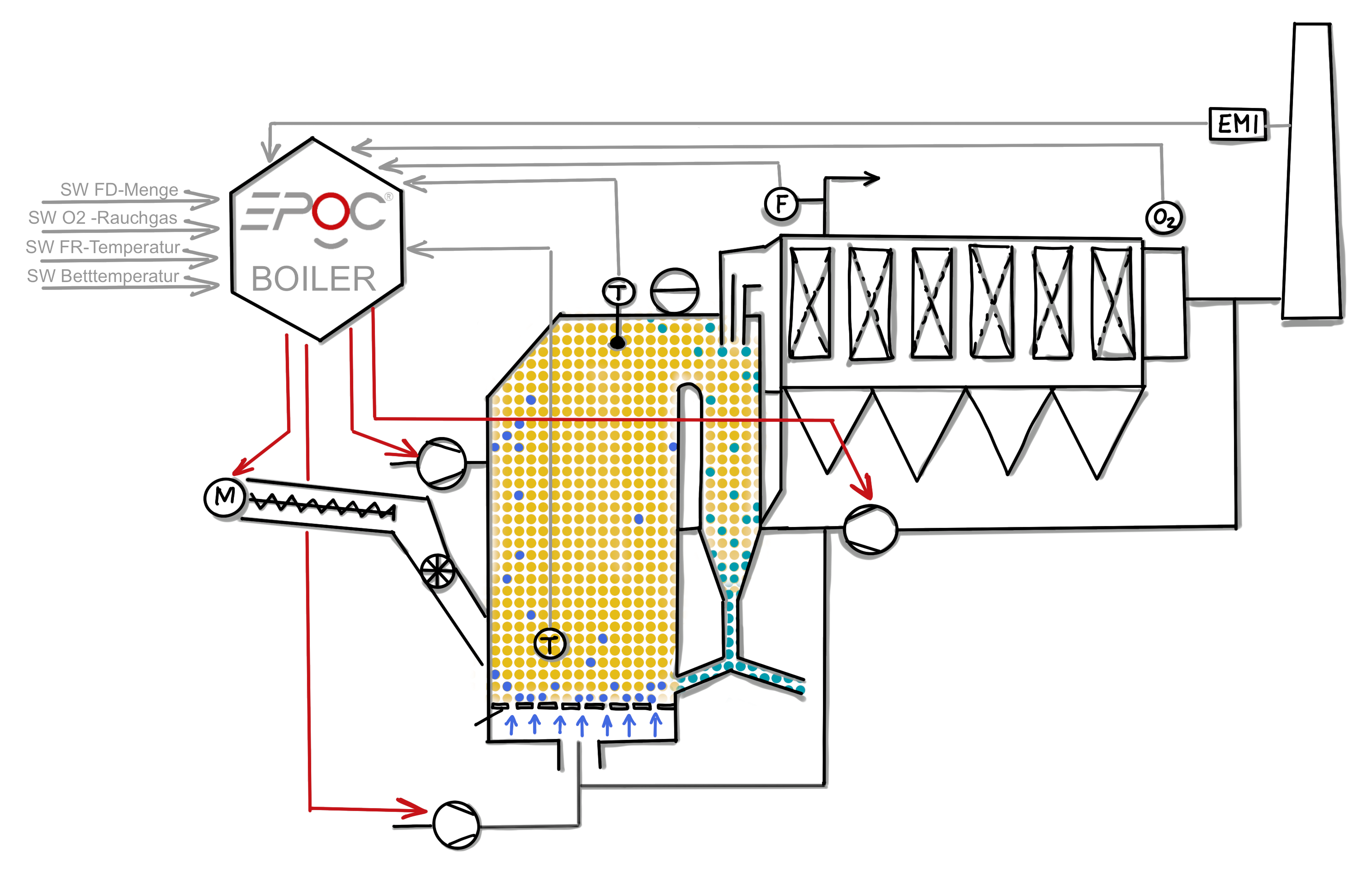

EPOC® boiler module for fluidized bed combustion

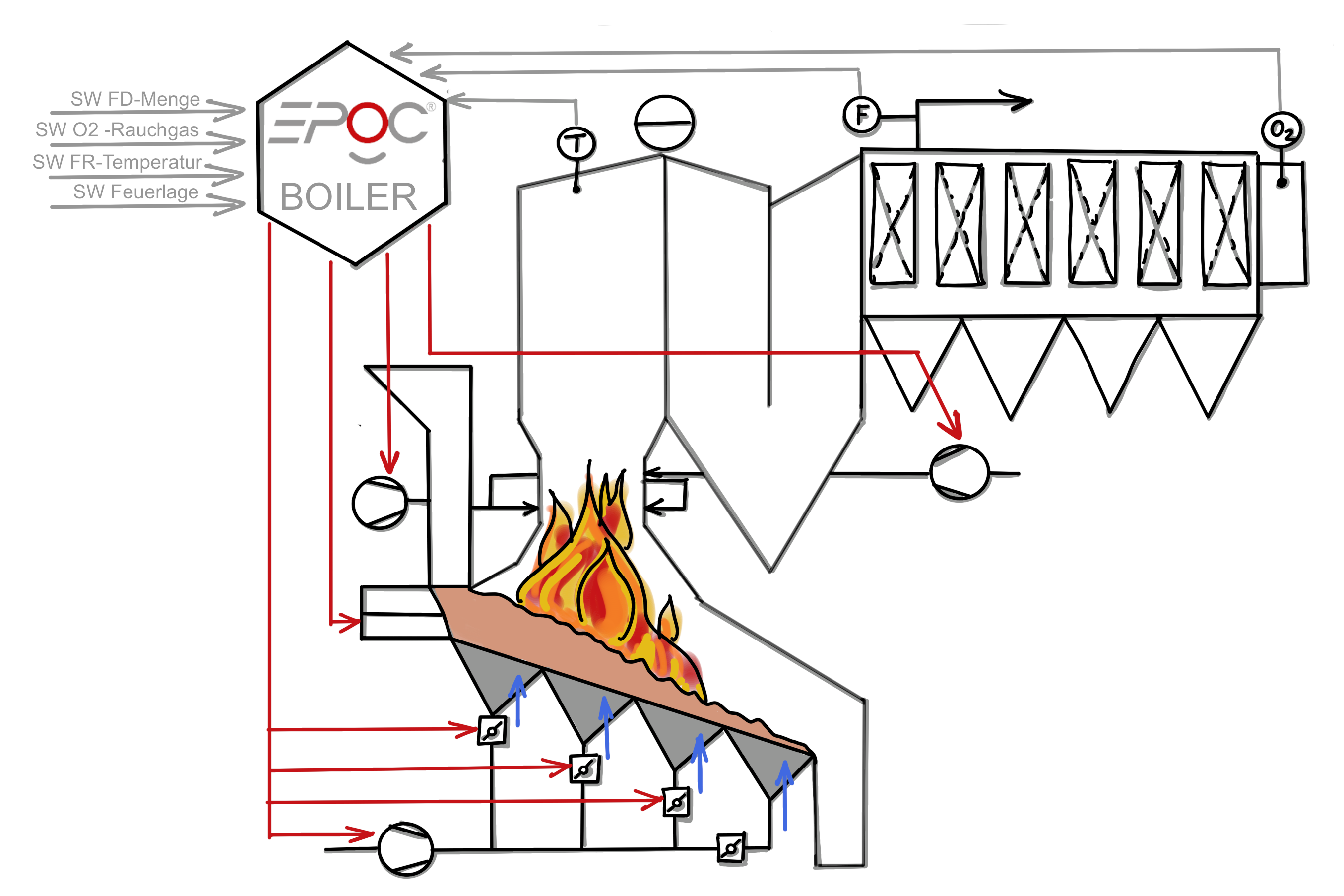

EPOC boiler module for grate firing

The types of boilers for which our firing rate controls can be used successfully include

Our firing rate control enables precise control of combustion in steam boilers to ensure efficient steam production with minimal emissions. By reducing steam pressure fluctuations, steam losses can be avoided and turbine efficiencies maximized. By adapting steam production to actual demand, unnecessary steam production that cannot be used is avoided.

Our firing rate controls can optimize combustion in hot water boilers to ensure a constant and reliable supply of hot water. The fire output control adjusts the fuel supply and air volume to the current heat requirement to ensure a constant hot water temperature. The control system continuously monitors the water temperature in the boiler and controls the fuel output accordingly to maintain the desired temperature.

The firing position control implicitly takes long time constants and dead times of the installed heat exchangers into account in order to minimize oscillation behaviour and thus ensures stable operation.

Our firing rate control ensures that the optimum ratio of air and fuel is maintained to guarantee efficient combustion and minimal emissions, even with difficult residual fuel compositions.

Our combustion control system optimizes the combustion of biomass to support sustainable energy production and reduce environmental impact. In order to deal with different fuel compositions and water contents in the fuel, the firing rate control reacts automatically to detected changes and adjusts the air volume and material feed accordingly for optimum drying and combustion.