This premise applied to the implementation of the BCS® project at the Innerratschings district heating plant in two ways. Firstly, it took the foresight of plant operator Erwin Schölzhorn and his team to make the decision to make the district heating plant fit for the future with our Biomass Control Solution (BCS®). On the other hand, the CONENGA Engineers enjoyed a wonderful panoramic view over the Ratschingstal valley during a hike to an alpine pasture.

Following the commissioning of the boiler with the BCS®-FLR firing rate control system in the first week, the BCS®-PSM network control and buffer storage management system was put into operation after a short breather in the mountains.

Following the commissioning of the boiler with the BCS®-FLR firing rate control system in the first week, the BCS®-PSM network control and buffer storage management system was put into operation after a short breather in the mountains.

The common experience and the interhuman exchange during the alpine hike promoted not only the mutual understanding and thus the project progress, but remain also particularly pleasant and certainly long in the memory.

Back to the project…

A special feature of the BCS® suite is the structure of the programming. On the one hand, the modular structure creates a good overview in the program code and, on the other hand, enables the step-by-step commissioning of individual system parts as well as uncomplicated extensions. Each structural or technical section of the system is mapped as such in the control system and the modules are then networked with each other.

The individual “automation layers” – signal processing, control technology, HMI user interface and data acquisition and evaluation – are also clearly separated and connected to each other via defined interfaces.

In operation, the modules and layers merge with each other in such a way that a uniform “seeing and experiencing” of the BCS® suite is possible and a product from a single source is created. This enables the plant operators to independently operate and monitor the entire plant from commissioning onwards.

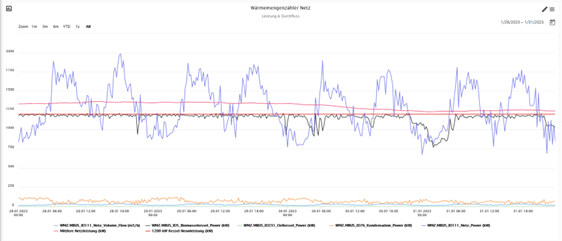

The system in Innerratschings has now been successfully in full operation with the BCS® since July 2022. This required some adjustment work, especially at the beginning, and further fine-tuning for operation at maximum output in winter (see illustration at full load operation).

In February 2023, the Holzkurier (specialist medium of the wood industry) also visited the district heating plant; the report with further information on this project can be found here: Use potentials, not just find them!