BioFizz: CO₂ capture rethought – temperature swing adsorption (TSA) as the key to climate-neutral food production

CO₂ is considered the main driver of climate change – but it can also become a resource. The BioFizz research project is investigating the techno-economic feasibility of temperature swing adsorption for the capture and use of CO₂ in the food industry. The aim is to make a contribution to the circular economy and climate-neutral industrial production.

Facts

Project start: July 2025

Duration: 10 months

Objective: To explore the techno-economic feasibility of an industry solution (food industry) for the capture and use of CO₂ based on TSA technology. This project is funded by the Climate and Energy Fund and the Federal Ministry for Innovation, Mobility and Infrastructure and is being carried out as part of the Energy Research Program 2025.

The challenge

The natural carbon cycle, in which CO₂ sources and CO₂ sinks (reservoirs) are balanced, is being thrown out of balance by human-induced carbon dioxide emissions. This imbalance increases the atmospheric CO₂ content. As a greenhouse gas, CO₂ indirectly causes the earth’s temperature to rise, as the heat radiation reflected from the ground can no longer escape sufficiently from the atmosphere. The excess CO₂ is mainly produced during the thermal conversion (combustion) of fossil and biogenic organic fuels, but also during biotechnological processes such as bioethanol production.

Energy plants that provide heat and electrical energy are still needed, however. According to the Intergovernmental Panel on Climate Change (IPPC), CO₂ capture technologies are therefore an indispensable element in the fight against climate change.

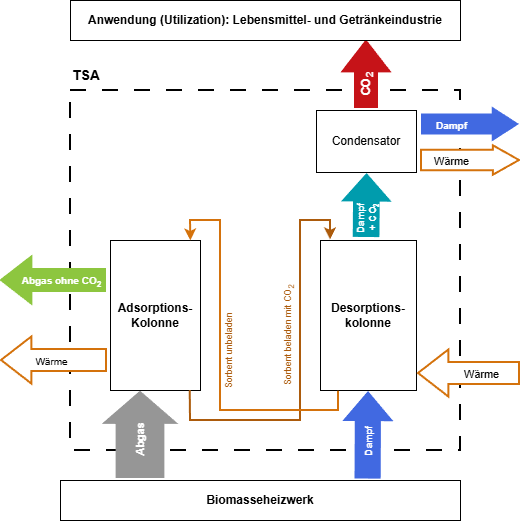

Post-combustion technologies are one way of capturing CO₂ The most advanced and already industrially applicable technology is amine scrubbing. The disadvantages of this technology are the high energy consumption and the handling of chemicals. Temperature swing adsorption (TSA) is seen as an alternative solution, the use of which is examined in more detail in this project. It was originally developed as part of the ViennaGreenCO₂ project at the Vienna University of Technology in cooperation with Shell.

What happens to the capturedCO2?

The FFG-funded research project “BioFizz” is investigating the suitability of using temperature swing adsorption (TSA) technology as a carbon capture (CC) method in conjunction with biomass energy plants. A suitable area of application appears to be the food industry, where there is a high energy demand andCO2 is required for direct use in various processes. In many cases, energy production with biomass is already available on site.

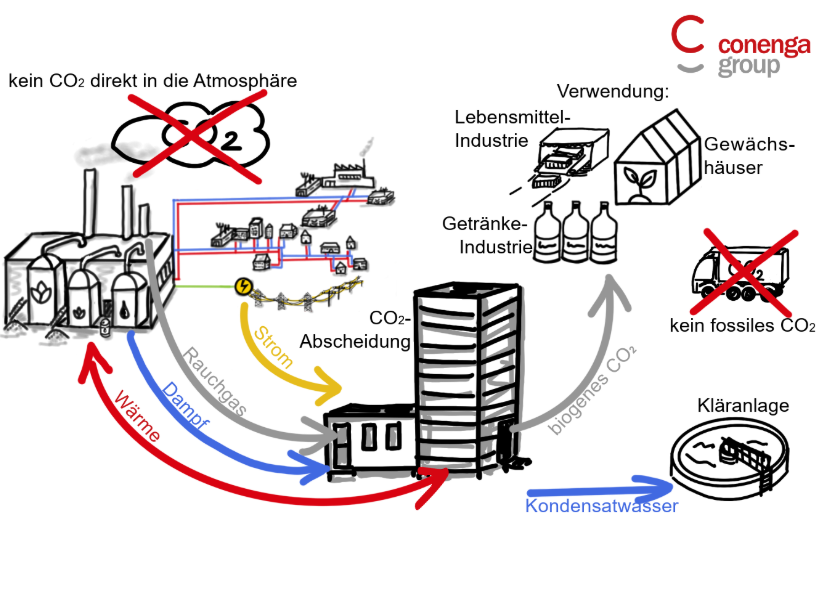

CO2 can then not only be seen as an emission or unwanted by-product in the thermal conversion process, but in captured form can also be considered as a product in the value chain in the food industry. The following figure shows an overview of this concept.

Objective: Carbon capture should release as little CO₂ as possible directly into the atmosphere, here using the example of a biogenic-fired plant including the utilization of CO₂ => Concept “BECCU – Bio Energie Carbon Capture and Utilization”

In line with the circular economy and the ecological and economic principles of sustainability, CO₂ is captured from the flue gas of the biomass heating plant, temporarily stored and then used in the industry’s production process or passed on to a geographically close user. In this way, not only the purchase of fossil-generated CO₂ can be avoided, but also the long transportation and its ecological footprint. In addition to the direct production of food and beverages, this principle can also be used to fertilize greenhouses, for example. Geological sequestration, i.e. the long-term storage of CO₂, can also be made possible in a sensible form.

Why temperature swing adsorption (TSA) as a technology?

Why temperature swing adsorption (TSA) as a technology?

The technology maturity level of TSA technology as a CC method is currently TRL5. The technology has so far only been implemented as a laboratory plant or on a pilot scale. The main advantages of TSA compared to amine scrubbing, which is already being implemented, are currently expected in two areas:

- Significantly lower energy requirement – the energy requirement is reduced by 1/3 as the liquefaction step will not be necessary to achieve the required purity.

- Significantly simplified handling – TSA is NOT a “chemical plant”, but a dry sorbent, which promises simple handling in the form of an elegant process engineering solution. The sorbent also offers the advantage that it is safe in contact with food.

Methods

The methods for achieving this goal can be divided into two main areas: firstly, the further development of the technology and secondly, the needs analysis of the relevant sectors.

Technology development

In this project, a feasibility study is being carried out to further develop the state of the art and show that there is a market for this specific application. Two methods are used for this purpose. Firstly, a model is being developed using the IPSEpro software. Secondly, one of the partners has built a TSA pilot plant in a preliminary project, which is now being used for test runs and further development of the product’s purity level.

Facts about the test facility:

- CO₂ product purity (January 2026): 95 % by volume

- CO₂ capture rate: > 90 %

- CO₂ capture capacity: 200 kg/d

Needs analysis

Needs analysis

When evaluating the implementation of new technologies, not only the functionality but also the requirements of the industry must be taken into account. The requirements of the market are analyzed by organizing workshops and conducting a survey among relevant industry representatives.

A topic will be prepared for each of the three workshops. Key notes and a moderated discussion will lead to the collection of data for industry requirements.

Focus of the workshops and survey:

- What are the needs of the industry?

- What are the technical, legal and organizational requirements for implementing a new TSA system in an existing system?

- What are the exact requirements for the product?

Results to date (January 2026)

Technology

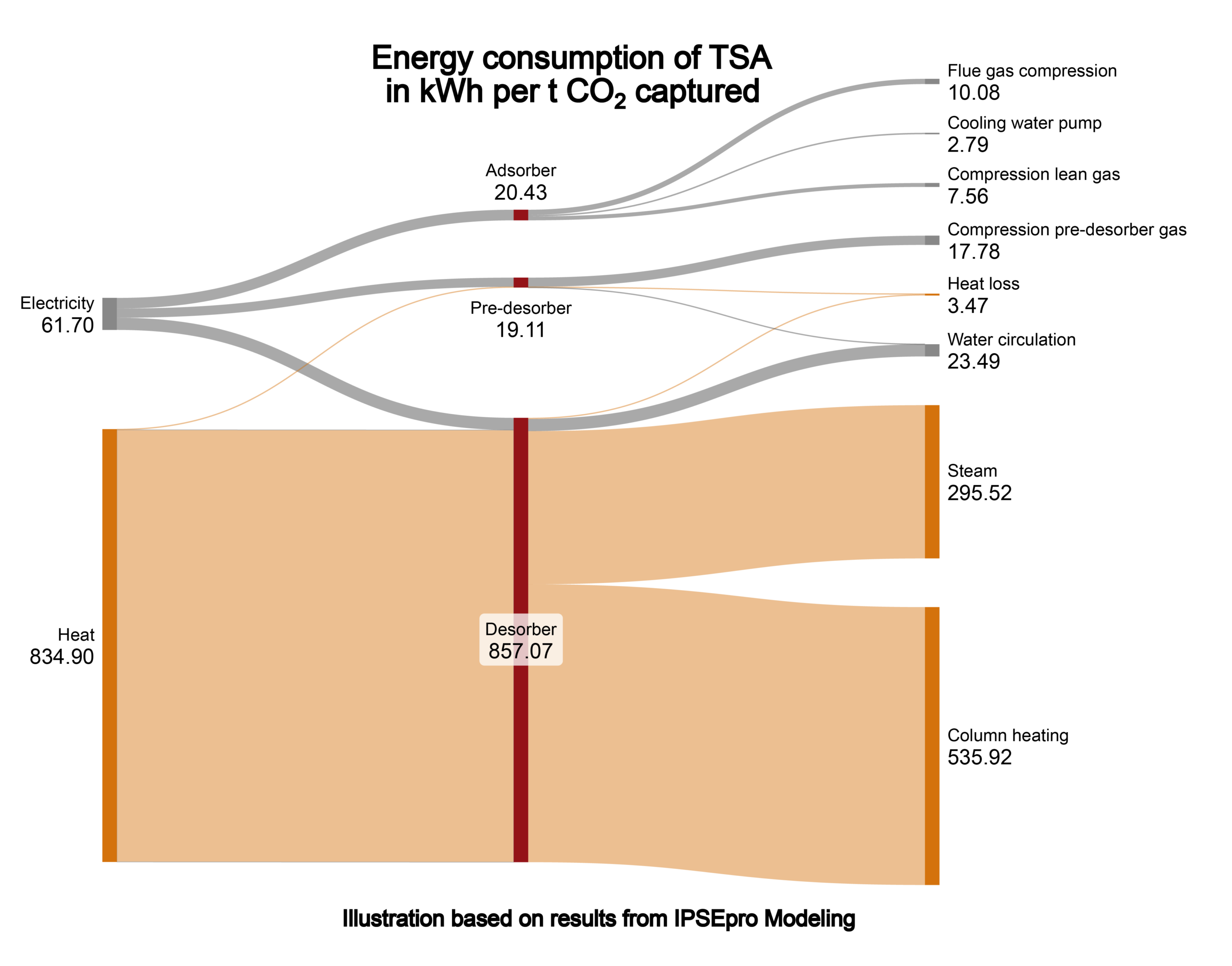

- According to IPSE modeling, there is a lower energy requirement for TSA compared to amine washing. The energy requirement determined is shown in the Sankey diagram below.

- Stable operating conditions were achieved in the pilot plant and a steady increase in product purity was achieved during the tests.

- Degradation of the sorbent at higher temperatures under the influence of oxygen has been detected. Sealing is required.

BOKU: Determined energy demand according to IPSEpro modeling of BOKU in the Sankey diagram

Industrial supplies

The following key requirements were identified

- A constant supply of CO₂ is required. This ensures process stability on the food production side.

- High product purity (in accordance with the EIGA standard) is a prerequisite for use in food production.

- Low CAPEX/ OPEX are required to be able to compete economically. The purchase costs of fossil CO₂ were used as a comparison, which vary depending on the location.

Target costs: <100 – 160 euros/ t CO₂

Outlook

The exploratory project will run until the end of April 2025, until then we will continue to work on validating the market for TSA technology. We are also actively working on a solution for the degradation of the sorbent and the possibility of trials with the laboratory plant using real flue gas.

If the legal requirements are met,CO2 can also be stored geologically. The sale of CO₂ certificates offers the opportunity of additional income. There is currently no legal framework for this in Austria. In countries such as Norway, CO₂ is already being actively sequestered. This option is also being actively explored.