Fluidized bed technology – robust key technology for industrial energy and material flows

From energy supply to the chemical and building materials industries to the circular economy, the demands on industrial plants are constantly increasing: fuels are becoming more heterogeneous, material flows more complex and emission limits more demanding. At the same time, availability, efficiency and flexibility must be guaranteed.

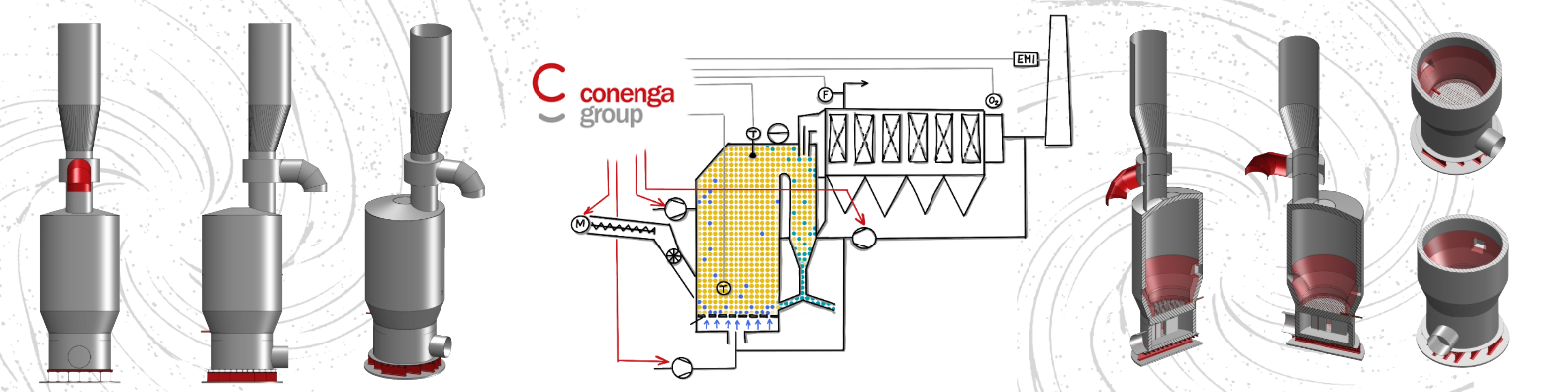

One technology that has accompanied us as the CONENGA Group for many years and is becoming increasingly important is fluidized bed technology. Not just as a combustion system, but as a robust technological basis for making energy and material flows manageable under real industrial conditions.

Technological core: Robustness instead of ideal conditions

In our view, what particularly distinguishes fluidized bed technology is its physical robustness. The principle of the fluidized bed ensures intensive mixing of bed material, fuels and additives. Temperature and material distributions are significantly more homogeneous than with many conventional processes.

In practice, this means

- Stable process conditions even with changing input materials

- Low sensitivity to fluctuations in grain size, moisture or calorific value

- Reliable heat transfer and reproducible process control

It is precisely these properties that make fluidized bed systems particularly suitable for demanding industrial applications with variable raw material quality.

Flexibility as a real operational advantage

In industrial energy supply, flexibility is no longer a nice-to-have, but a decisive competitive factor. Fluidized bed systems can process a wide range of fuels – from biomass of varying quality to biogenic residues and substitute fuels.

From the point of view of system operators, this offers clear advantages:

- Greater security of supply

- Less dependence on individual fuel sources

- Better adaptability to changes in the market and availability

At the same time, the fluidized bed offers favorable emission behavior. The comparatively low combustion chamber temperatures reduce the formation of NOₓ and sulphur compounds can already be bound in the process. In combination with modern flue gas cleaning, strict environmental regulations are also met in the long term.

Interface between energy and material flows

The fluidized bed shows its particular strength where energy and material flows are combined. Materials are not only used to generate energy, but also undergo targeted thermal treatment or conversion.

This makes the technology particularly relevant for:

- Chemical industry, for example for thermal pre-treatment or reactive processes

- Building materials industry, where constant process conditions are crucial despite variable raw materials

- Circular economy, when energy use and material recycling are considered together

As CONENGA, we therefore never view fluidized bed systems in isolation, but always as part of an integrated energy and process system and support them throughout their entire life cycle with a focus on control, stability and long-term operational reliability.

Our services in concrete terms

Our services in concrete terms

We support our customers with:

- Analysis of operational stability, efficiency and emission behavior

- Development and implementation of advanced control and automation concepts

- Optimization, conversion and adaptation of existing fluidized bed systems

In this way, fluidized bed technology is not only operated safely, but also strategically developed further.

Practical examples from CONENGA’s optimization work

The fact that the strengths of fluidized bed technology described above are proving their worth in everyday industrial applications can be seen in numerous projects that we have been involved in over the last few years. What they have in common is that the technological robustness of the fluidized bed was already in place – the decisive levers were in operation, control and the further development of existing concepts.

The automation of fluidized bed operation by means of Advanced Process Control led to UPM Schongau led to stable steam production close to the process limits, reduced emissions and significantly fewer manual interventions, despite highly fluctuating fuel qualities.

In the conversion project Norske Skog in Bruck an der Mur, existing combustion and control concepts were optimized and supplemented with an SNCR system. The result: permanently lower emission limits and greater operational safety – without the need for new construction.

Also in the project at Styromag also demonstrates the potential of modern fluidized bed installations: High flexibility with organic raw materials, stable temperatures and reliable operation thanks to well thought-out design and modern control technology.

Conclusion:

Fluidized bed technology is a robust key technology for industrial energy and material flows – especially where flexibility, emission control and circular economy come together.

Fluidized bed technology is a robust key technology for industrial energy and material flows – especially where flexibility, emission control and circular economy come together.

In the webinar “Fluidized Bed Combustion” on March 4, 2026, the experts from the CONENGA Group will address this exciting topic.

Register now!

Dipl.-Ing. Johann Sauermann ist Senior Management Consultant bei der CONENGA Group und seit 2022 für die Koordination und Abwicklung von prozess- und regelungstechnischen Optimierungsprojekten im industriellen Umfeld sowie für die Innovationskoordination verantwortlich. Sein Fokus liegt auf der Begleitung komplexer Veränderungsprozesse an der Schnittstelle von Technologie, Management und Organisationsentwicklung.

Mit rund 30 Jahren Erfahrung in der Beratung und Projektleitung verfügt Johann Sauermann über tiefgreifende Expertise in der Strategieentwicklung, der Digitalisierung sowie der Einführung integrierter, prozessorientierter Managementsysteme. Vor seinem Wechsel zur CONENGA Group war er unter anderem als Seniorberater und Projektleiter bei FACT Consulting sowie als Leiter der Organisation und Öffentlichkeitsarbeit an der FH Campus Wien tätig.

Neben seiner Beratungstätigkeit engagiert er sich intensiv in der Aus- und Weiterbildung, unter anderem als Vortragender in MBA-Programmen, Trainer für die Quality Austria sowie als Assessor und Validator für Excellence nach dem EFQM-Modell. Diese Verbindung aus technischem Fundament – basierend auf seinem Studium des Maschinenbaus an der TU Wien – und seiner Kompetenz als systemischer Organisationsberater ermöglicht es ihm, ganzheitliche Lösungen für moderne Industriebetriebe zu entwickeln.

Expertise:

- Projektkoordination und -abwicklung im industriellen Umfeld

- Strategieentwicklung und prozessorientierte Managementsysteme

- Systemische Organisationsentwicklung und Change Management

- Qualitäts-, Umwelt- und Projektmanagement

- Führungskräfteentwicklung und Moderation von Fachworkshops

Fokusbereiche bei CONENGA:

- Leitung prozess- und regelungstechnischer Optimierungsprojekte

- Koordination technologischer Innovationen

- Durchführung von Assessments nach dem EFQM-Modell

- Gestaltung von Lern- und Entwicklungsdesigns für Kundenprojekte