Optimized fuel efficiency as the key to sustainable industrial production

![]() In times of rising commodity prices, the efficient use of combined heat and power plants has become a strategic necessity. At CONENGA, we ensure fuel efficiency by combining different measures.

In times of rising commodity prices, the efficient use of combined heat and power plants has become a strategic necessity. At CONENGA, we ensure fuel efficiency by combining different measures.

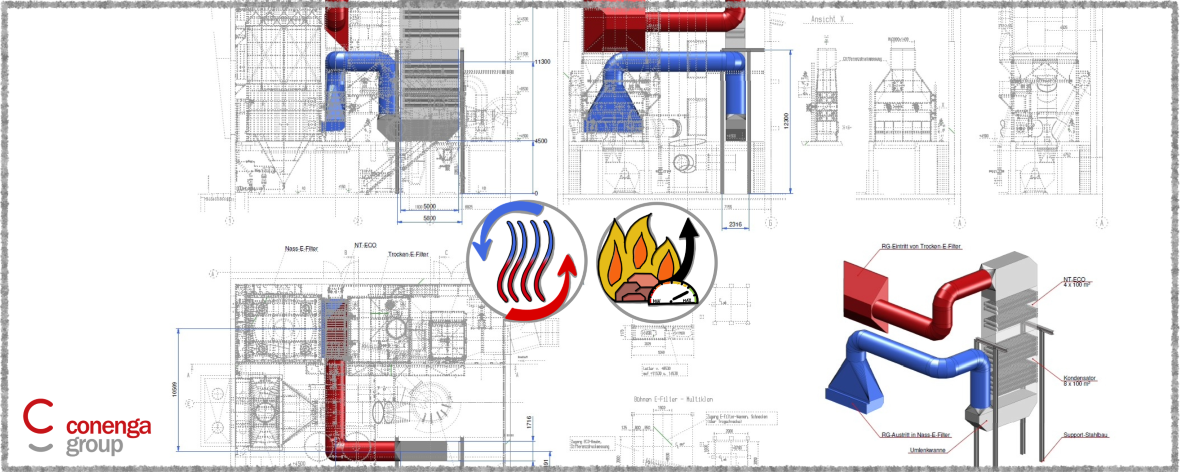

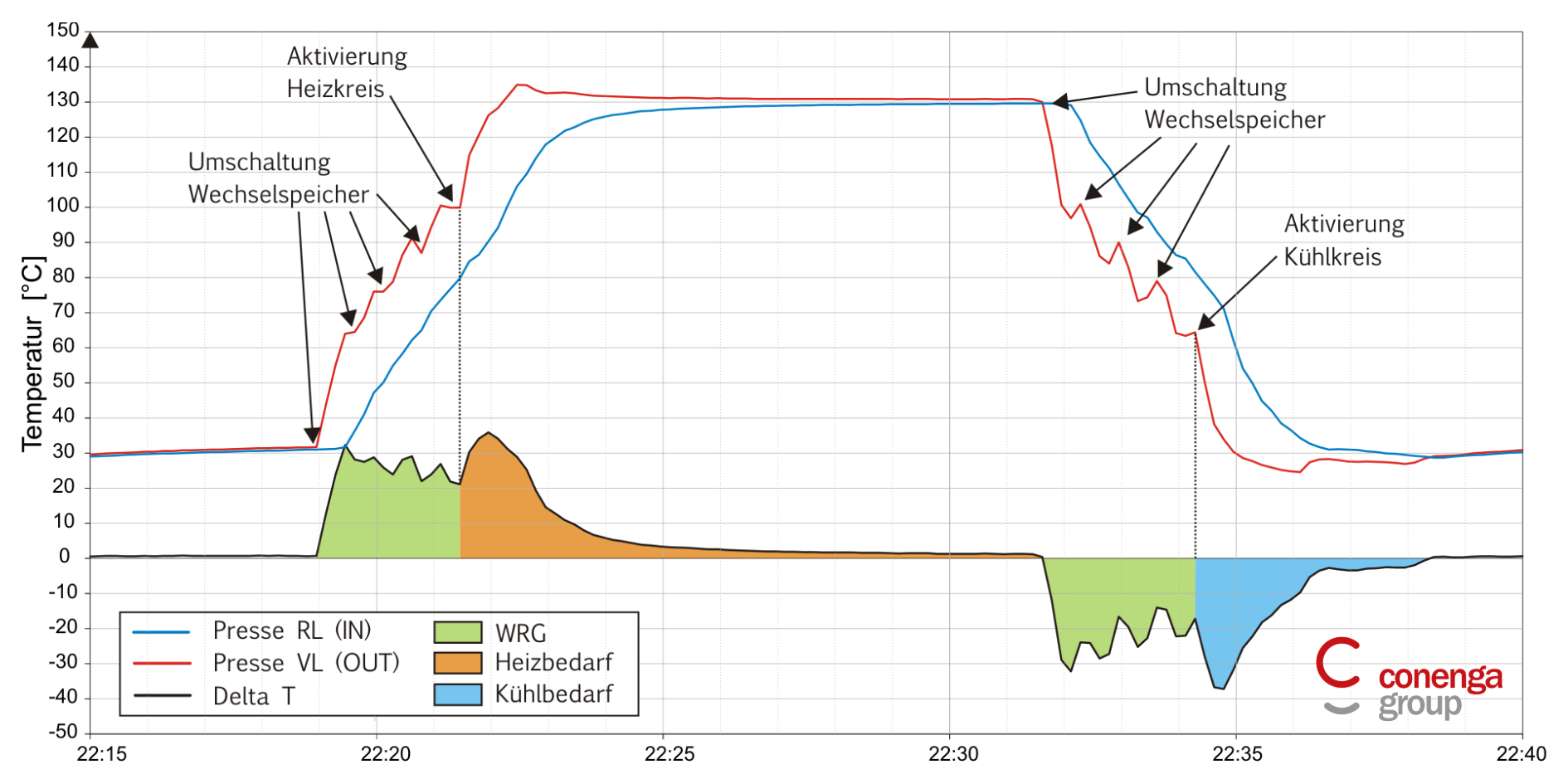

In addition to sophisticated control technology for continuous and optimum control of the combustion process – and thus a consistently high boiler efficiency – we also see heat recovery from flue gases and various coupled heat pump technologies as integral components of holistic energy optimization of industrial systems.

Holistic view of energy flows

Every industrial plant – whether power plant, incineration plant or production line – has

We rely on a combination of process engineering expertise, precise measurement technology and digital data evaluation. By systematically analyzing energy flows, we identify potential, optimize combustion processes and adapt control strategies.

Heat recovery as an efficiency lever

Heat recovery as an efficiency lever

A central element of our projects is heat recovery – both from flue gases and from process or cooling media.

Whether through the use of economizers, air preheaters, innovative heat exchanger systems or special flue gas condensation systems – we develop and implement solutions that are individually tailored to the respective process, regardless of the industry.

When designing such systems, the focus is not only on maximum thermal output but also on operational sustainability and long-term cost-effectiveness: every measure must function reliably during operation and pay off in the long term.

Digitization and monitoring as a success factor

We have developed online diagnostic tools that enable real-time process data analysis to ensure optimum operation at all times.

In this way, efficiency potentials – such as contamination, the optimization of control strategies and measurement technology or other influencing factors – become visible at an early stage and can be continuously exploited.

Our experience shows: The greatest leverage often lies not in costly conversions, but in the intelligent use of existing systems – with precise and stable control and well thought-out process management.

Sustainability with technical depth

Fuel efficiency and heat recovery are not isolated tasks – they are part of an overall strategic approach. If fuel is used more efficiently, not only are costs reduced – CO₂, NOₓ and other emission values are also reduced in relative terms.

With our optimization projects, we contribute to the decarbonization of industrial processes – without compromising on efficiency or operational safety.

With our optimization projects, we contribute to the decarbonization of industrial processes – without compromising on efficiency or operational safety.

The expertise of CONENGA Engineers helps companies to operate their systems more efficiently, sustainably and future-proof.

Marketing & Mediendesign bei CONENGA Group