Successfully implementing optimization projects – How to turn challenges into real progress

In industry and the energy sector, there is growing pressure to optimize processes, reduce energy costs and achieve decarbonization targets. Whether in power plant control, thermal energy systems or industrial production processes – successful optimization projects are crucial to ensuring efficiency and competitiveness.

But how can such projects not only be launched, but also implemented sustainably and successfully? We know this from our many years of experience: Success lies not only in the technology, but also in the way we work together – internally and with our customers in the overarching project team.

Our strength lies in the combination of technical know-how, experience and an efficient project architecture based on cooperation, trust and clear structures.

The project start: When the problem calls

The project start: When the problem calls

A project often starts with a burning problem: a technical fault, excessive heating costs or the need to increase energy efficiency. The WHY is usually quickly identified (cutting costs, reducing CO2, …) but the HOW and WHAT often remain vague: where to start? What is the right lever?

Several success factors are helpful for quick orientation at the start of the project

- Understanding and visualizing complexity

- Asking the right questions consistently, understanding the context of the topic

- Narrowing down and structuring the challenge in line with the systems approach

- Work with assumptions and hypotheses in early phases – test and adapt them

Shaping and deepening cooperation

In addition to analyzing technical systems, we pay particular attention to the social process of collaboration. Trust reduces effort.

Our success principles for fruitful collaboration

- Visualize: Sketches and process images help to promote shared understanding

- Fact-based analysis: decisions are made in a comprehensible manner

- Making initial successes visible early on: promotes acceptance and strengthens project participation

- Secure resources: Employees who only take care of optimizations “on the side” quickly run into conflicting goals

- Actively practicing internal communication: Transparency about progress, challenges and results strengthens process trust

Stabilize and stay on course

Stabilize and stay on course

After the successful project launch, the challenging implementation phase follows. We pay attention to the following principles:

Important success factors:

-

- Allow course corrections: Not every initial assumption holds up in practice

- Transparency of effort and costs: clear coordination prevents misunderstandings

- Maintain communication: Regular coordination and joint decisions ensure long-term project success

Define and complete sub-projects and make successes visible

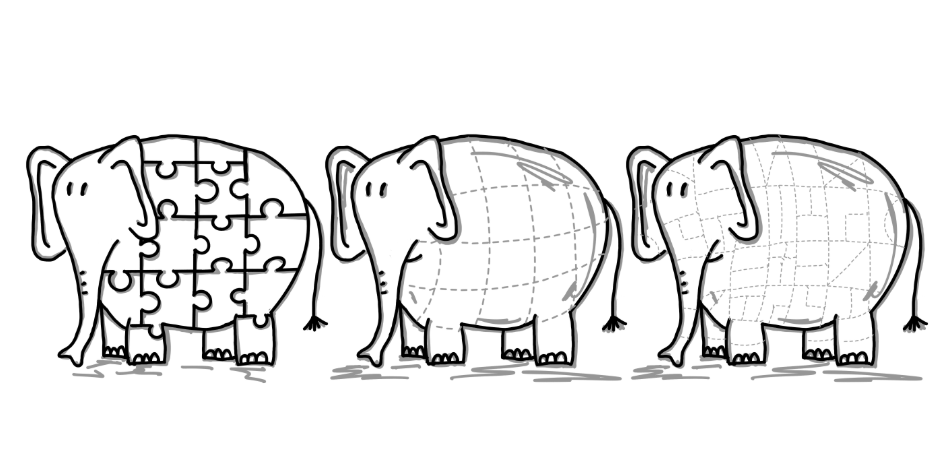

And now the elephant comes into play: “How to eat the elephant? Piece by piece.” The following applies right from the start: large projects become successful when they are broken down into manageable sub-projects.

Therefore, pay attention to important success factors:

- Making improvements visible, documenting and recognizing them

- Deliberately set up before and after comparisons – not just on demand

- Fact-based benefit analyses, targeted communication so that success does not fizzle out

- When all the parts have been completed, it is also important to consciously bring the whole thing to a close, to honor and dissolve the project team and thus clear the mind for something new

Conclusion

If optimization projects are set up correctly in organizational terms, they translate technological excellence into real economic benefits.

The following applies to industrial companies, energy suppliers and power plant operators: technological innovations only develop their full value through structured cooperation and strategic anchoring.

The following applies to industrial companies, energy suppliers and power plant operators: technological innovations only develop their full value through structured cooperation and strategic anchoring.

With a clear process, open communication and methodical organizational development, optimization projects become sustainable success factors – technically, economically and humanly. CONENGA is a strong, competent partner for your optimization projects.

Marketing & Mediendesign bei CONENGA Group