Hazard analysis using the HAZOP study – Plant safetyin the (wood)industry

Plant safety is of paramount importance in every industry, and the wood industry is no exception.In a holistic hazard analysis, it is crucial not only to consider the obvious hazards posed by machinery and equipment, but also to comprehensively record and take into account the process-related risks, such as those that can occur when burning wood. It is therefore advisable to think outside the box in order to identify potential hazards.

A proven method of risk reduction is to carry out a hazard and operational readiness analysis, or HAZOP for short. This identifies potential hazards, evaluates and classifies the risks.

What is a HAZOP study?

HAZOP stands for Hazard and operability (Hazard and Operability). The focus is on identifying hazards during system operation, with personal safety being the top priority. The “operability” part relates to the operability of the system and the search for ways to simplify this. By defining protective measures, deviations in operation can be identified and rectified at an early stage.

When is a HAZOP study conducted?

A hazard analysis is carried out before a system is commissioned for the first time. However, a HAZOP study may also be required when converting or updating safety systems. A safety and hazard analysis is a mandatory requirement in binding EU directives and their legal implementation in national regulations such as the Machinery Directive and the Pressure Equipment Directive. In all these cases, it is important to utilize the existing knowledge of experts and to ensure that all relevant safety aspects are taken into account through a methodically sound approach.

How does a HAZOP study work – the implementation

A HAZOP study requires a multidisciplinary team of engineers, technicians and safety experts. Objectives and requirements are jointly defined in order to systematically identify, assess and document risks.

The procedure includes the delimitation of the scope of consideration, the definition of target functions, the identification of deviations, the evaluation of consequences, the classification of risks and the definition of countermeasures.

Definition of the scope of analysis

Clear demarcation of the analysis areas (e.g. boiler, furnace and flue gas path).

Define target functions

Definition of the intended operating sequences (e.g. process of conveying solid fuels into the furnace).

Identifying deviations

Use of key words to identify deviations from target functions in order to detect potential hazards.

Evaluate consequences

Assess the consequences of deviations (e.g. an increase in output with potential damage to the boiler and the impact on people).

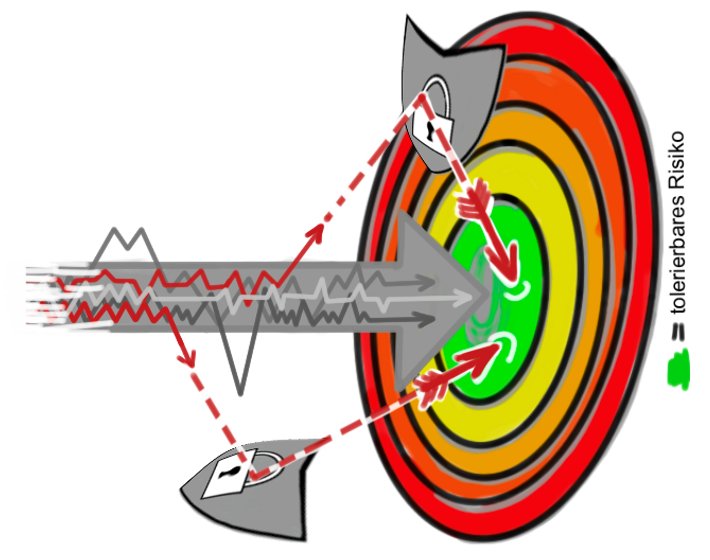

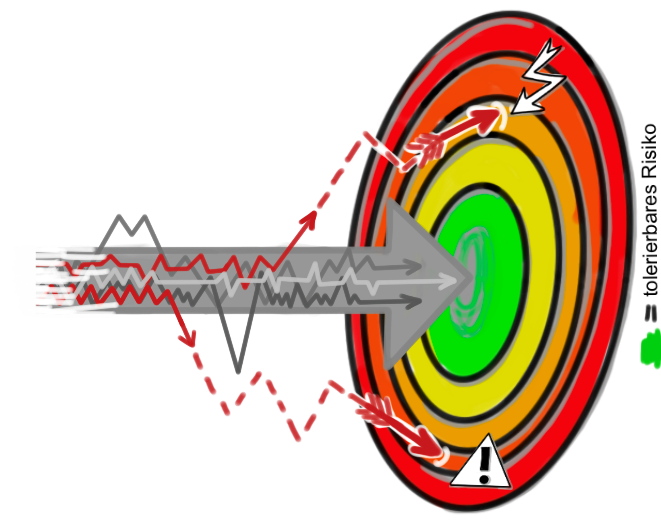

Classify risks

Evaluation of risks using parameters such as extent of damage, probability of occurrence, …

Definition of countermeasures

Derivation of required safety functions based on the hazard classificationCreation of a shutdown matrix and programming instructions for implementation in the automation technology.

Implementation

The hazards and required safety functions identified in the HAZOP are implemented on the system. This includes connecting the sensor signals to a safety PLC and programming function plans (FBDs) to automatically initiate countermeasures via actuators.

Conclusion

Safety and efficiency are critical in the timber industry. HAZOP studies provide an effective method to identify and assess potential risks. By taking proactive measures, companies can not only improve safety in the workplace, but also increase their competitiveness through improved operability. The engineers from the CONENGA Group team support companies in ensuring the best possible plant safety at their facilities. Find out more about the topic here.