The Welsberg Niederdorf district heating plant cooperative was founded in 2001 in Welsberg in Alta Pusteria (South Tyrol) and has since been supplying the two communities with environmentally friendly district heating. Two biomass boilers and a flue gas condensation plant of the company VAS are available for this purpose. At the end of 2012, following the continuous expansion of the district heating network, a thermal oil boiler and another flue gas condensation plant from Agro were put into operation. In addition to generating hot water, the thermal oil boiler with ORC module can also be used to produce green electricity and feed it into the power grid.

Status analysis

The district heating plant was visited and the current challenges of operating the plant were discussed with those responsible. During operation of the thermal oil boiler, there are regular drops in output, which prevents a permanently high level of green electricity production. This results in a loss of potential revenue from the sale of green electricity. From the operating data of one year transmitted to us, we were able to derive, visualize and also quantify the possible limitations and savings on a fact-based basis, in order to enable an economic decision-making basis for the operators.

Project planning and implementation

The evaluation of operating data has shown that the potential for increasing green electricity production is very high. The aim of our project was to increase the current limitations with control technology optimizations and minimally invasive process engineering adaptations.

In a detailed analysis on site, the current limitations in electricity production were analyzed in detail, the causes of the limitations were revealed and a plan for project implementation was drawn up. In the summer, small process engineering adaptations were made to the thermal oil boiler as part of the boiler overhaul and measurement sensors were retrofitted.

After the thermal oil boiler was restarted at the end of August, we visited the district heating plant again and commissioned the BCS control modules on site within one week.

Commissioning of fire power control and buffer storage management system

The core element of this project was the new fire output control (BCS FLR) for the thermal oil boiler. With the help of this control, the maximum boiler output can be run at a constant level, which means that green electricity production is also permanently exhausted. It soon became apparent that the process engineering adaptations had brought about the expected improvements.

In addition, the BCS modules buffer storage management (BCS PSM) and load hierarchy management (BCS LHM) were programmed in advance and then put into operation on site. Particularly in the transitional period, the boilers can be operated quietly and constantly with forward-looking management of the buffer storage tank.

This is then reflected in high electricity production. In order to maximize electricity generation, the thermal oil boiler is prioritized.

The BCS modules and the corresponding parameterization interface were already carefully prepared in the offices of CONENGA Group, so that the commissioning of all BCS modules could be carried out on site on the first day. Subsequently, the firing position and the trends were closely monitored, manual flaps were adjusted and the controllers were tuned. With these small tuning or optimization steps, the BCS control modules were adapted to the plants on site to ensure the most efficient operation possible.

Achieved optimization results

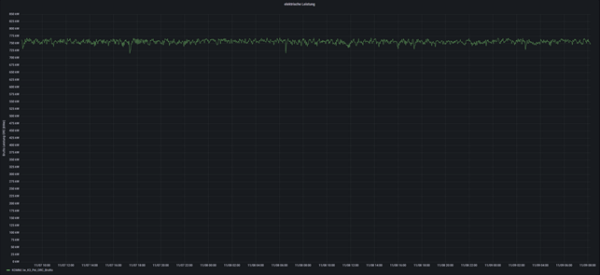

Already the first weeks after commissioning show a very pleasing picture. Green electricity production is within the target range for maximum electricity generation and the fluctuations in electricity generation have been significantly reduced.

The Holzkurier was also able to see our great work for itself during a site inspection – click here for the article.

After commissioning, the individual controllers will be further optimized to achieve the best possible result. In the course of this project, a service and maintenance contract for the BCS modules was also concluded. This ensures that our customers receive simple and uncomplicated support from the experts at CONENGA Engineers even after the project has been completed.

Fig.1: Optimal buffer storage management

Fig.2: Constant electric power generation @750 kWel