Project reference: Mercer Timber

With primary combustion technology measures for low NOx emissions – without SNCR

Potential study, efficiency increase through EPOC® boilers, adaptation of the plant safety chain, reduction of NOx emissions

The challenge

As part of the potential study carried out in advance by CONENGA Engineers, several control and process engineering improvement options were identified at the Saalburg-Ebersdorf site.

There was a need for action, particularly in terms of the efficiency and stability of the firing rate control and with regard to safe compliance with the increasingly stringent NOx emission limits.

Objective

- Increased efficiency through improved system control

- Adaptation of the plant safety chain incl. HAZOP study and TÜV approval

- Reduction of NOx emissions to ensure compliance with future limits

Implementation

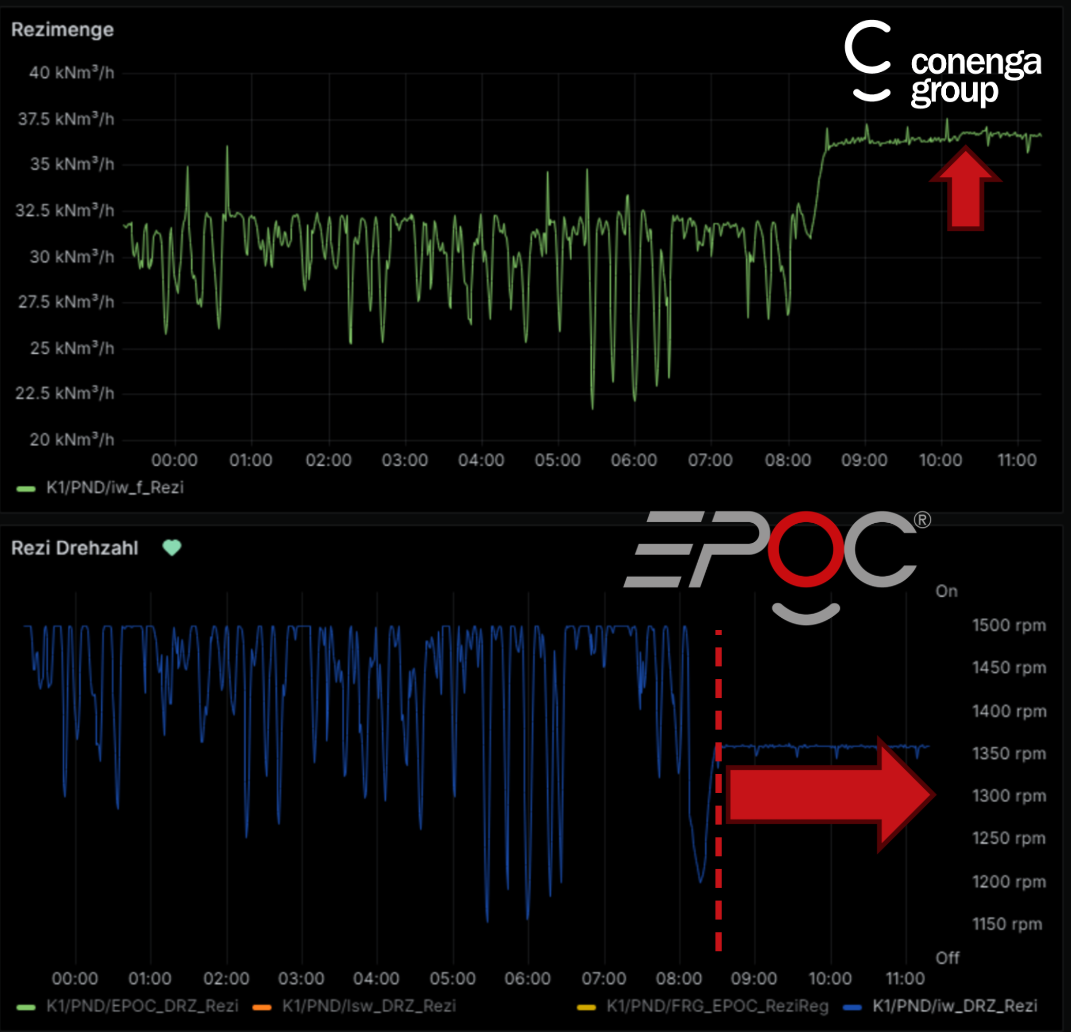

Increased efficiency with EPOC® boilers

Implementation of a largely automatic control system for more efficient operation at all load points. In addition to a modern HMI with simple operation, manual interventions have been reduced, operating modes standardized and the degree of automation increased (e.g. air damper settings are now automated). The firing rate control has been optimized in terms of stability and dynamic load behavior (including live steam pressure and additional primary circuits), boiler output and efficiency (ECO/Luvo) have been increased, downtimes have been minimized and travel time has been extended.

Adaptation of the plant safety chain

The safety chain was comprehensively revised and adapted to current requirements. To this end, HAZOP workshops were held, the SIF safety functions were updated and an overall BosB 24 concept was developed. The implementation was carried out with a fail-safe PLC, which enables precise diagnosis of triggered safety circuits. Acceptance by the TÜV.

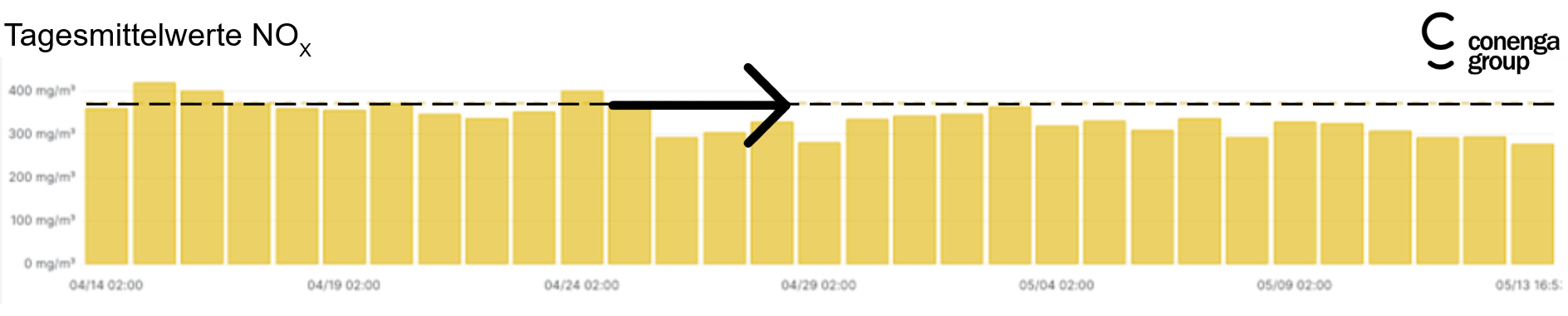

Emission reduction

The aim was to reduce NOx emissions in order to safely comply with the future limit value. Based on the potential study, a reduction was implemented through combustion technology measures in order to avoid the investment and operating costs of an SNCR system.

Results

More efficient operation

More stable control of live steam pressure and other process variables. Since commissioning, the

- Reduction of manual interventions and standardization of driving methods

- Increasing the degree of automation

- Optimization of firing power control (stability, dynamics)

- Increase in boiler output and efficiency (ECO/Luvo)

- Extension of travel time, minimization of downtimes

Greater system safety

- Comprehensive HAZOP study as the basis for targeted adjustment and optimization steps

- Existing knowledge of the system compiled and documented

- Safety chain comprehensively revised

- Updated system-related documents

Sustainability & emissions

The emission values remain permanently within the standard range below the 2025 tightened limit values. Costly investments in an SNCR system for flue gas denitrification were avoided.

- Reduction of emissions by 15-20 %

- Avoidance of a cost-intensive SNCR system