Deployed controller technologies

Deployed controller technologies

Diverse requirements and challenges in the process industry are encountered by various control technologies. Considering simple processes with stable and linear characteristics, conventional PID controllers pose a cost-effective and efficient choice. Due to their fast and precise reactions these controllers are suitable for a wide range of applications.

Complex and non-linear processes, on the other hand, require more advanced control technologies such as fuzzy logic controllers or neural networks. These technologies are capable of handling complex correlations and changes in the course of the process. Facing processes with slow dynamics and multiple input and output variables, Model Predictive Control (MPC) offers an efficient solution as it predicts and optimizes future states.

However, the accessibility of process data, safety requirements and available resources sets the framework for the selection of the most suitable control technology. Providing examples, adaptive controls achieve best results for processes whose characteristics change over time, whereas predictive algorithms enhance energy efficiency and production quality. Nonetheless, the most reliable and appropriate control algorithms often result from a combination of different technologies.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am looking forward to answering your questions

Sebastian Sturm is your expert concerning controller technologies

Controller technologies

In model predictive control approaches, a mathematical model of the process is deployed. Subsequently, the model output and the real process variables are compared continuously and enable the prediction the future behavior of the process.

Furthermore, this prediction passes through a real-time optimization to find the optimal manipulated variable for the current time step. Consequently, significant improvements are to be achieved as your process control reacts faster and in a robust manner.

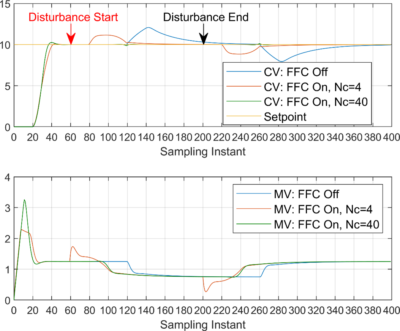

Considering known disturbances in the target function enables compensation for disturbances with very long dead times without critical controlled variable deviation by means of appropriate feed-forward control (FFC).

Considering known disturbances in the target function enables compensation for disturbances with very long dead times without critical controlled variable deviation by means of appropriate feed-forward control (FFC).

MPC offers significant advantages in the control of non-linear systems. Among others, the implicit embedding of manipulated variable constraints as well as the possibility to optimally operate systems very close to these constraints add to the pros. Furthermore, the simple extension to multi-variable systems and the model-based consideration of system dead times are clearly beneficial.

Especially the control of the latter system class represents a typical application of model predictive control structures.

Model Predictive Control (MPC):

-

Utilizes a dynamic model of the process to predict future states and develops optimal control strategies

-

Particularly suitable for systems with slow dynamics and multiple input and output variables

-

Deployed in the oil and gas industry, the petrochemical industry and the food industry

Your advantages of MPC control at a glance

-

Control of multi-measurement systems (MIMO) with an MPC

-

Integrate disturbances model, minimize control error

-

Consideration of non-linearities

-

Reacting to known future setpoint changes

-

Direct compensation of dead times

-

Direct consideration of static/dynamic constraints

-

Optimize the process at each time step

-

Accelerate transient process changes

-

Minimize losses due to setpoint changes

-

Enable stability verification

Complex and multi-dimensional problems are easily mapped to neural networks, as any number of complex non-linear effects can be represented.

However, this approach is only applicable if large amount of process data is available and the model output is strictly limited to plant states present in these process data (extrapolation impossible).

Neural networks independently extract relevant correlations from large amounts of data. Hence, they provide a valuable complement to physical-logical modeling, which is often insufficient or only feasible with a great deal of effort.

Neural networks rely on artificial intelligence to model and control complex processes. Pattern recognition enables them to recognize and adapt to non-linear relationships in the process. Thus, a main field of application is related to predictive maintenance.

In practice, we deploy neural networks as so-called black-box models.

We address the following problems with neural networks

-

Non-linear system identification

-

State observer design

-

Controller design

-

Neural adaptive control

-

Neural optimal control

-

Reinforcement learning

-

NLq stability theory

-

PID controller (proportional-integral-derivative controller):

-

Widely used and versatile

-

Consists of three components: the proportional, the integral and the differential part

-

Used to control processes where fast and precise reactions are required

PID controllers are the most versatile type of controller. We adapt the controller behavior to your specific application using a variety of practical approaches:

-

Intelligent min/max limits

-

Situational freezing of the controller output

-

Feed-forward control

-

Gain scheduling for different controller dynamics

-

Anti-windup for cascade controls

-

Limiting controllers that are switched through to the controller output by a min/max selection

-

Controller tracking when the controller is inactive for skip-free switching

Fuzzy logic controller:

-

Uses fuzzy logic to control complex and non-linear systems

-

Particularly useful when mathematical modeling of the system is difficult

-

Frequently used in the chemical industry and in the control of combustion processes

In order to achieve optimal control performance and generate long-term added value, we also incorporate concepts from the field of fuzzy control in the sense of holistic APC solutions into the respective specific customer solutions, depending on the problem and objective.

Adaptive control

-

continuously adjusts the control parameters to take account of changes in system behavior

-

is suitable for processes in which the properties change over time

-

applied in the automotive industry and in the control of bioprocesses

These control technologies are selected and adapted according to the specific requirements and challenges of the respective process. The combination of several technologies can also lead to optimal results.