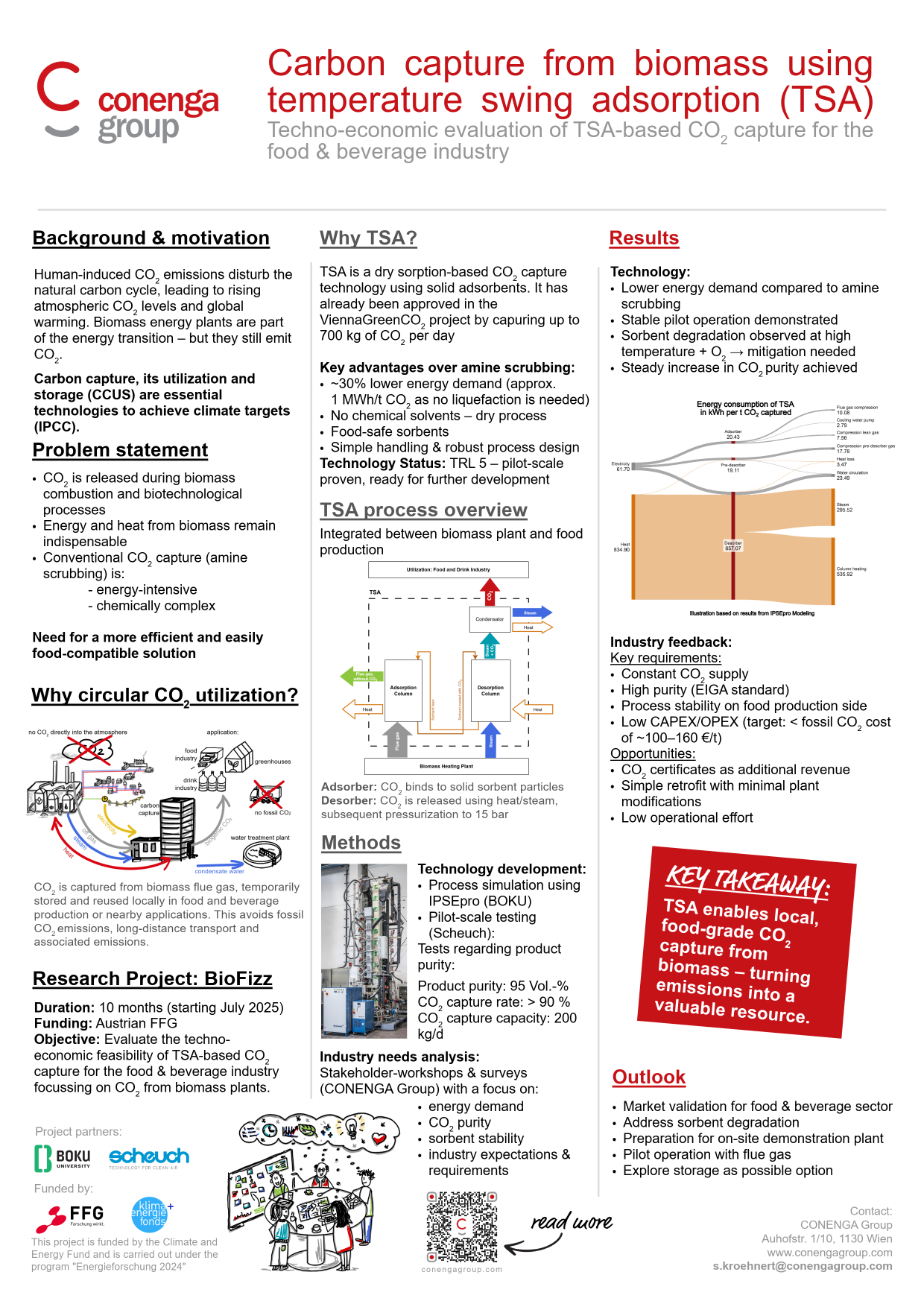

CO₂ separation / carbon capture

CO₂ separation / carbon capture

Why CO₂ capture?

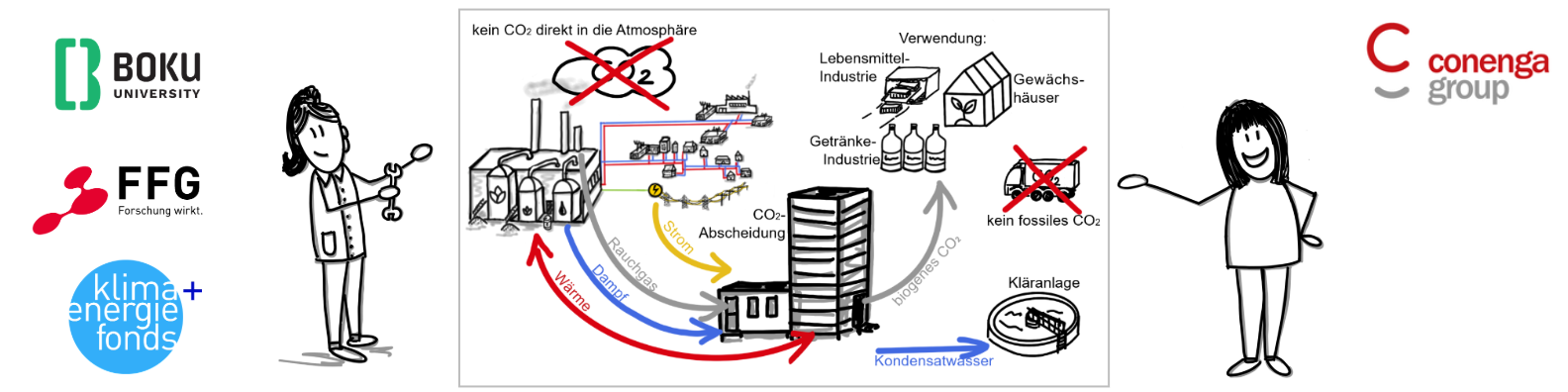

The challenges of climate change require decisive action. Achieving the 1.5°C target of the Paris Climate Agreement requires not only emission reductions, but also negative emissions – i.e. the active removal of CO₂ from the atmosphere. The CONENGA Group is working intensively on both approaches – with a particular focus on technical carbon capture.

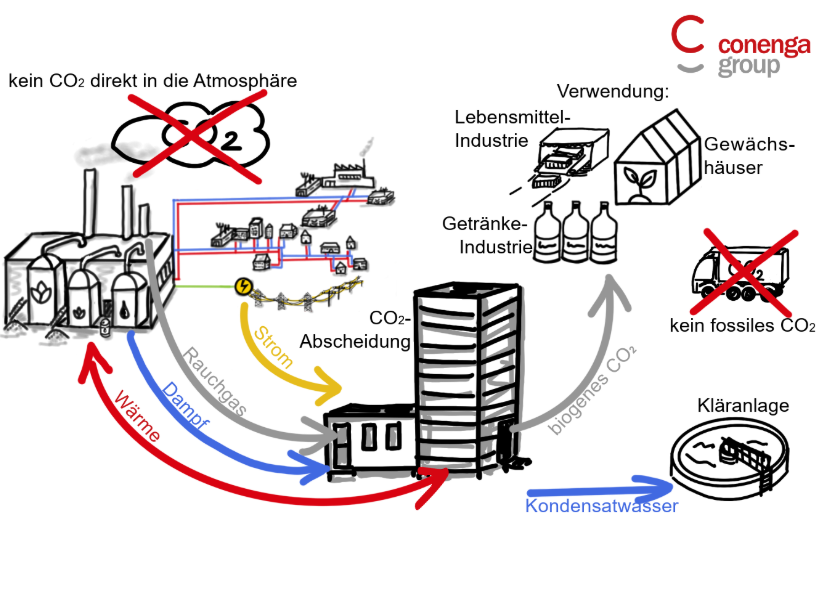

The thermal utilization of fossil fuels unbalances the natural carbon cycle. CO₂ accumulates in the atmosphere and increases the greenhouse effect, making the earth warmer and warmer. As heat and energy generation, including through combustion processes, remain necessary, CO₂ capture offers a key opportunity to reduce emissions directly at source – especially in industrial plants.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am looking forward to answering your questions

Sabrina Kröhnert is your expert concerning CO₂ separation!

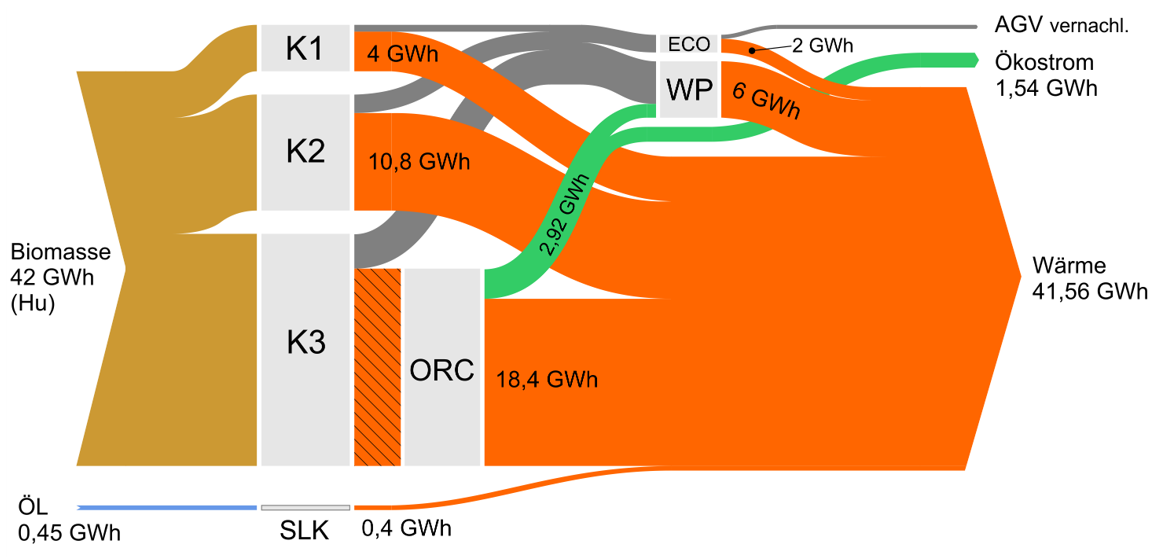

Our focus: carbon capture for biogenic plants

The CONENGA Group specializes in retrofitting and optimizing CO₂ capture technologies in biogenic-fired plants. Our engineering teams analyze individual site conditions and develop tailor-made solutions.

Our core technologies

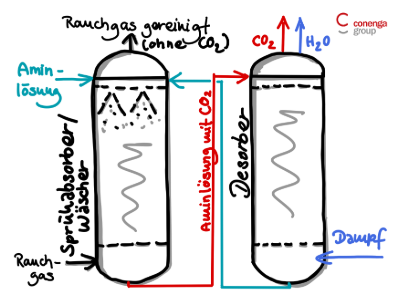

CO₂ absorption (amine scrubbing)

Amine scrubbing is the most established process for CO₂ separation. The CO₂ reacts with an amine solution and is separated and released in two steps (absorber and stripper).

Advantages:

- High separation efficiency

- Industrially proven and available

Challenges:

- Relatively high energy requirement, especially with high purity requirements

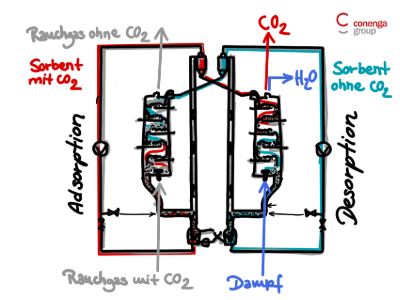

CO₂ adsorption (TSA)

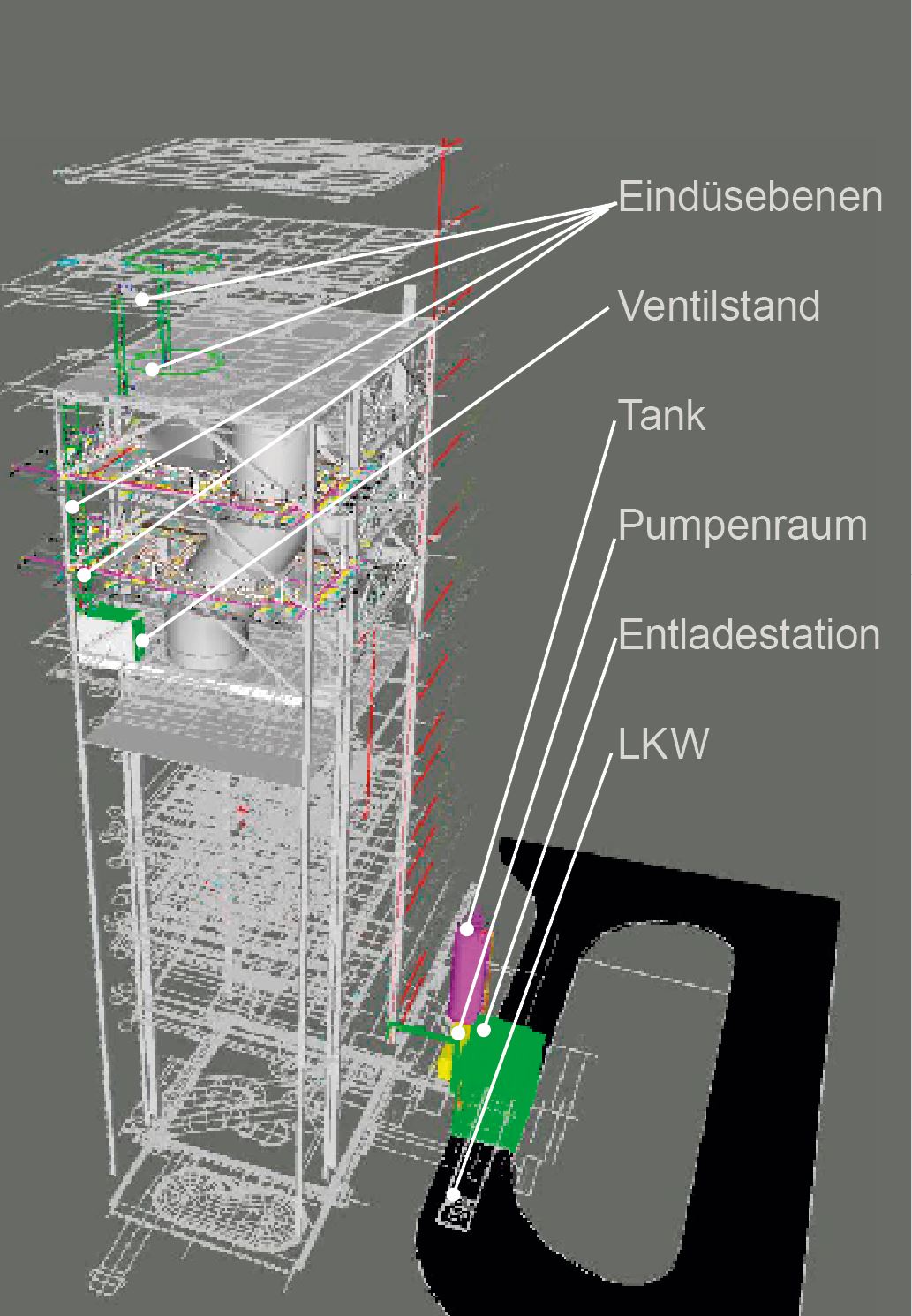

In TSA technology, CO₂ is bound to solids by adsorption and released again by increasing the temperature in the desorber column. The CONENGA Group continues to develop TSA systems for industrial applications.

Features:

- High potential energy efficiency

- Use of flexible sorbents

- Configuration as fluidized bed or fixed bed reactor

This technology is currently still in the development phase, but shows great potential for industrial applications with high purity requirements.

Your technology partner for CO₂ capture

With comprehensive expertise in process engineering, energy technologies and project implementation, the CONENGA Group offers holistic solutions for carbon capture – from analysis to implementation. Together with our customers, we shape the path to decarbonization.

Further information:

Development and innovation

The CONENGA Group is involved in various research projects for the further development of adsorption processes and alternative carbon capture technologies. Our aim is to give our customers access to sustainable solutions at an early stage.

The CONENGA Group is involved in various research projects for the further development of adsorption processes and alternative carbon capture technologies. Our aim is to give our customers access to sustainable solutions at an early stage.

Read more about this in this blog post!