Project reference: UPM Schongau

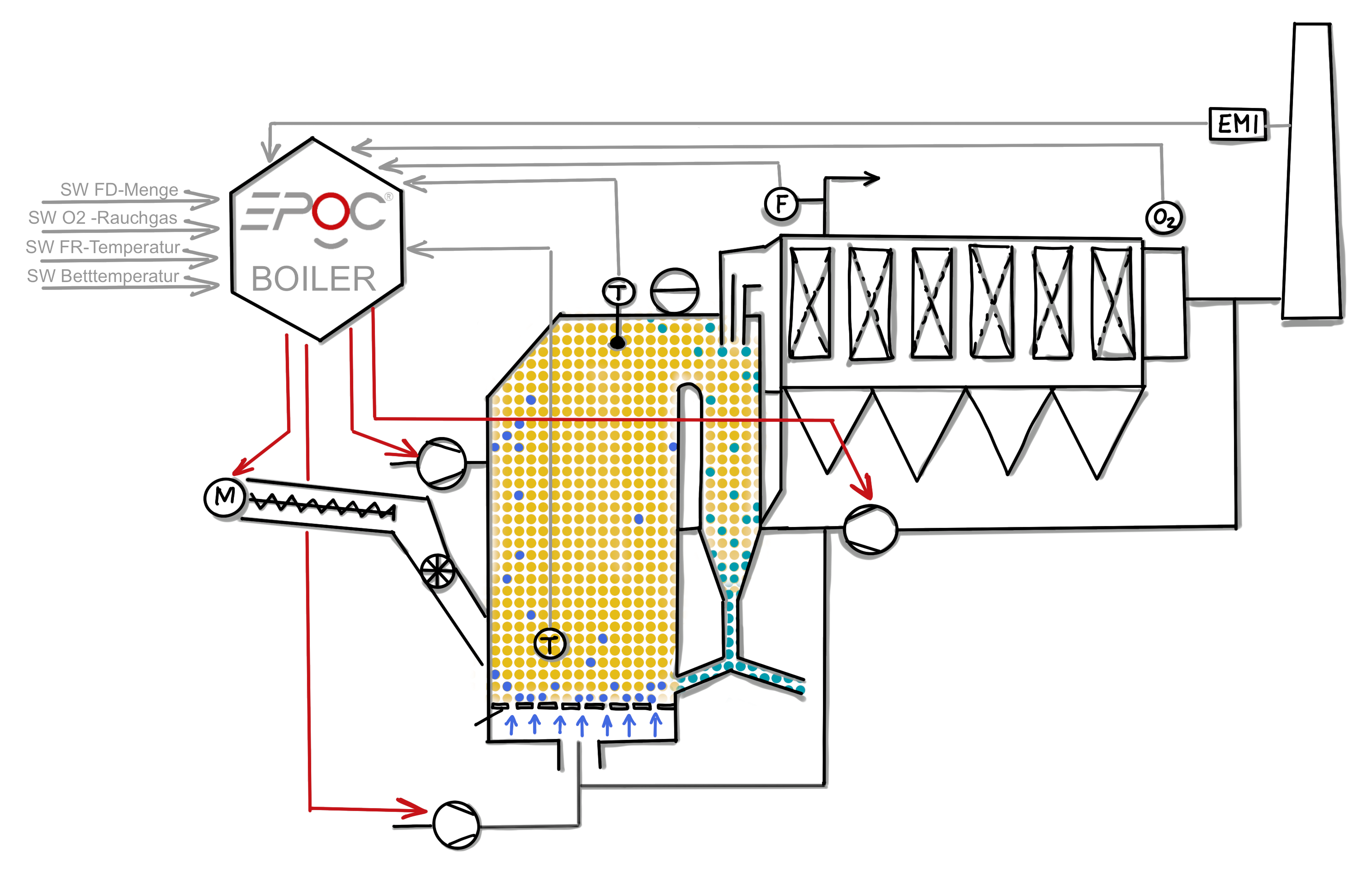

Optimization of the fluidized bed boiler HKW 2

The challenge

The manual operation of the fluidized bed boiler HKW 2 led to numerous operator interventions and an uneven boiler output due to fluctuating fuel qualities.

Objective

The aim of the project was to implement an intelligent, higher-level firing rate control (FLR) to stabilize the operating mode, reduce emissions and relieve the plant operators.

Solution approach:

A preliminary study (pre-check) highlights an annual optimization potential of at least € 240,000 through the use of a modern Advanced Process Control (APC) concept. The EPOC® Suite was selected as a tailor-made solution for control optimization.

Advantages of the EPOC® Suite

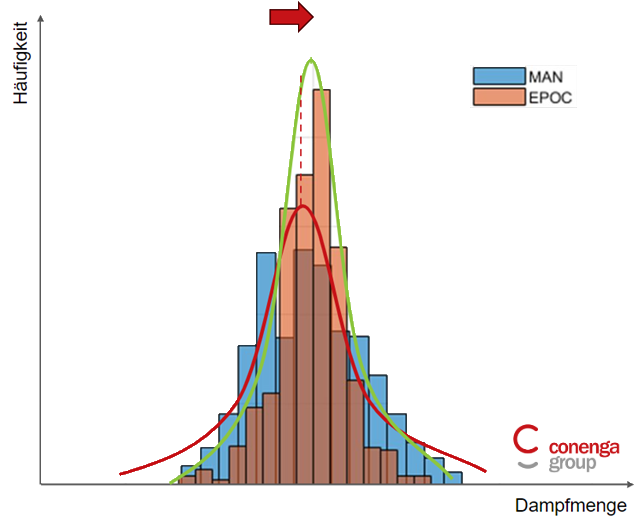

- Uniform boiler output and avoidance of load drops.

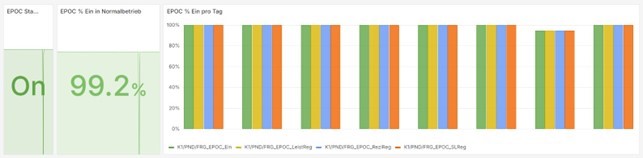

- Increased automation with reduced manual intervention.

- Optimization of fuel flexibility and stabilization of steam management.

- Compliance with emission limits for CO and NOx.

- Increased efficiency by reducing gas consumption, caking and cleaning downtimes.

Implementation

Project phases

Pre-check: Initial assessment of potential and coordination of objectives.

Potential study: Detailed analysis and concept development for FLR.

Implementation: Engineering, delivery, commissioning and adaptation of the FLR using the EPOC® Boiler Module.

Conclusion: The implementation of the EPOC® Suite marks a significant step towards stable, low-emission and economically optimized boiler operation. The long-term collaboration offers additional potential for further optimization, particularly in fuel management.

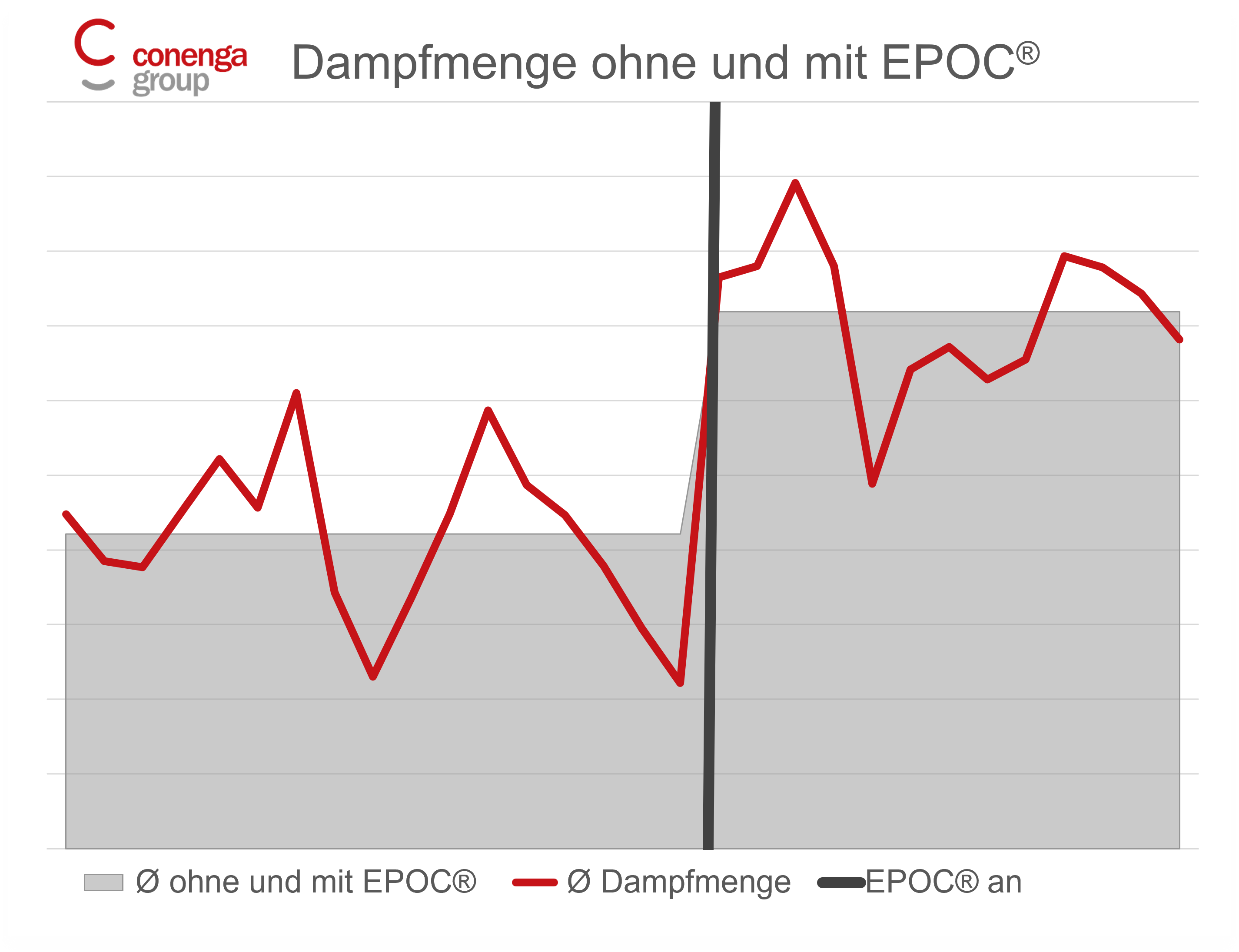

Results

- Significant increase in steam production

- More renewable electricity

- Less natural gas

- CO2 savings

- Additional revenue

- No negative impact on emissions

The use of the EPOC® Suite supports:

- Uniform combustion, constant combustion chamber temperatures

- Dynamic adaptation to changing fuel compositions

- Maximizing steam production

- Minimization of gas consumption in HKW 2

- Reduction of boiler caking

- Maximizing travel time through precise fire control

- Permanent compliance with legal emission limits

- Increase degree of automation, minimize manual intervention

Customer testimonial

“The potential for optimizing control technology in process plants often remains untapped. With the EPOC® Suite and the in-depth know-how of CONENGA’s experts in the field of “Model Predictive Control”, we have seized this potential in our fluidized bed power plant and can look forward to significant CO2savings and an increase in the amount of live steam.”

“The potential for optimizing control technology in process plants often remains untapped. With the EPOC® Suite and the in-depth know-how of CONENGA’s experts in the field of “Model Predictive Control”, we have seized this potential in our fluidized bed power plant and can look forward to significant CO2savings and an increase in the amount of live steam.”

Dipl.-Ing. Michael Merkel, Manager Energy Strategy, UPM Schongau