Demonstration plant for the calcination process of magnesite

STYROMAG Steirische Magnesitindustrie GmbH, based in Tragöß-St Katharein, Styria, Austria, has been producing magnesium oxide (MgO) since 1870. In 1985, the first and still the world’s only fluidized bed furnace for the production of caustic-burned magnesite was built.

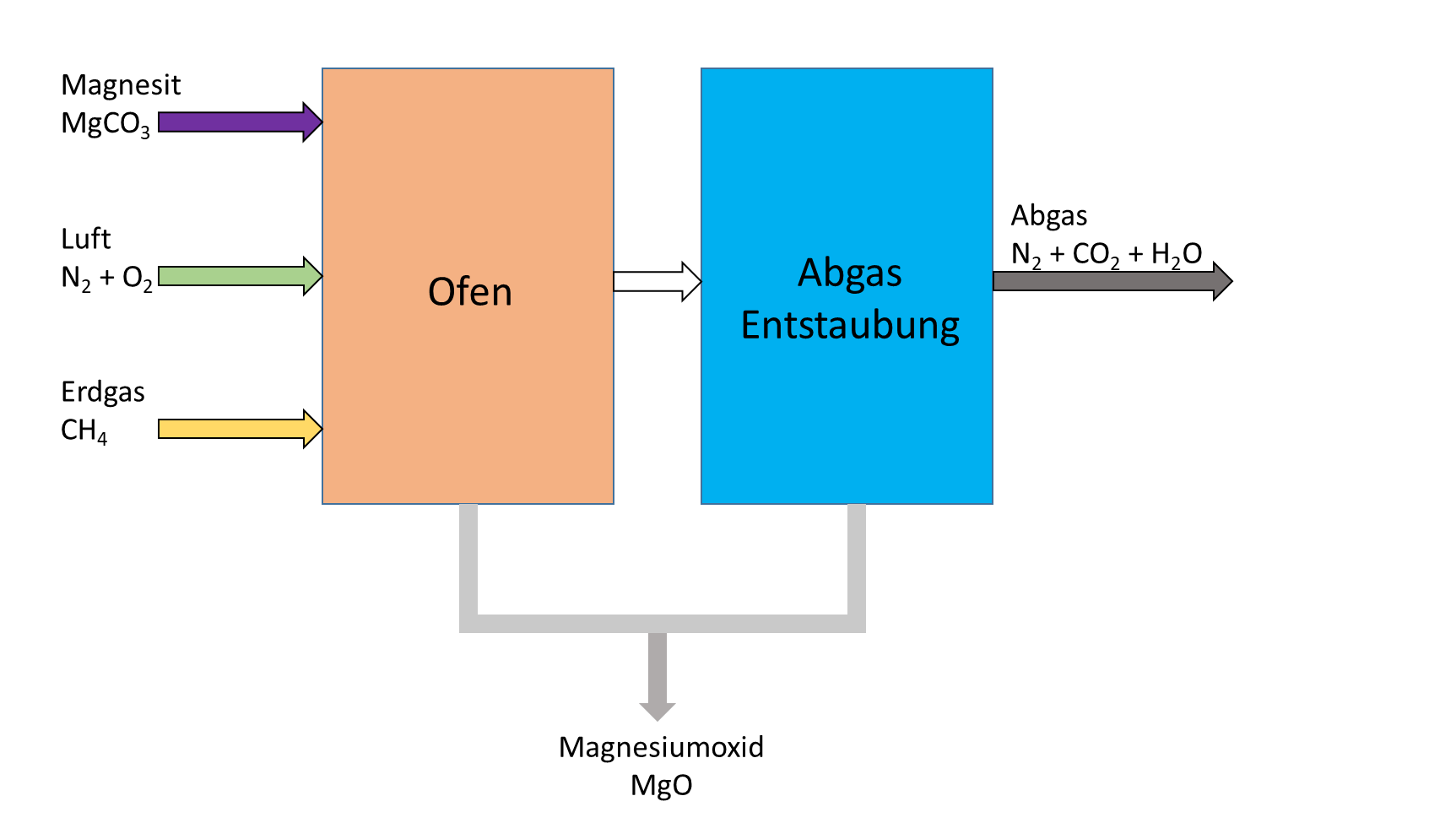

The fluidized bed produces 19,000 tons annually. The fluidized bed furnace is where magnesite is calcined to magnesium oxide, a process that produces CO2 (see Fig. 1 process diagram).

Fig. 1 process diagram

The fluidized bed process is characterized by the fact that impurities remain as residues in the reactor. This allows a high degree of product purity to be achieved. This process takes place in the fluidized bed at around 790 °C. The energy required to raise the temperature and for calcination is supplied by natural gas.

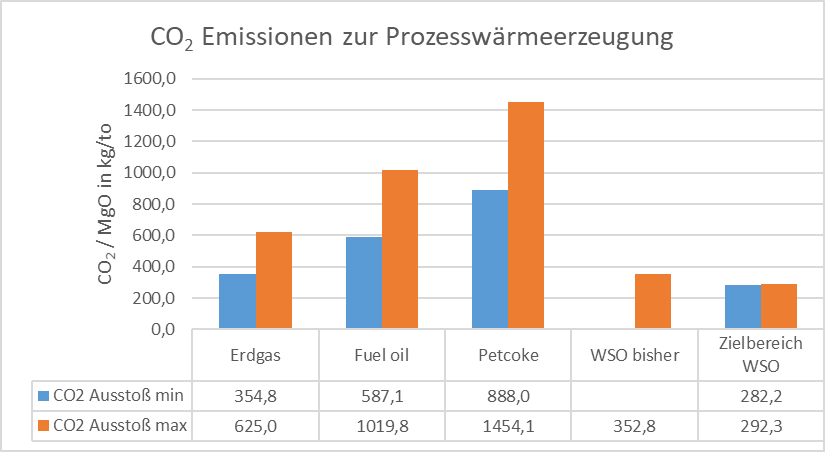

In 2018/2019, the idea arose to modernize this manufacturing process. With the collaboration of CONENGA Engineers, this modernization was also used to optimize energy efficiency. Another project goal was to set a new, outstanding benchmark in terms of energy efficiency and CO2 emissions throughout the industry (see Figure 2) and to achieve this as part of a demonstration project.

Figure 2: Specific CO2 emissions from process heat generation during Mg calcination

Optimization measures for greater sustainability

Heat recovery is already partially implemented in the existing process in a multi-stage procedure (raw stone preheater, exhaust gas cooler for combustion air preheating).

The innovative energy integration optimized by CONENGA Engineers now ensures maximum heat recovery throughout the entire process. Both the use of primary energy from natural gas and the plant’s own electricity requirements can thus be reduced by approximately 20%. Our specified advanced process control optimization measures for optimized process control are also expected to significantly reduce CO2 emissions by 1,165 tons per year.

As part of this project, we are also working with the manufacturer to develop a new type of heat exchanger that can withstand very high temperatures and extreme dust exposure thanks to innovative technology and a robust design. The demonstration project thus integrates solutions and innovations for numerous aspects of the MgCO3 calcination process.

A technology project by CONENGA Engineers

In the “Energy and Process Engineering” division of CONENGA Engineers, the technical concept was developed and refined to implementation maturity under the leadership of Mr. DI Dr. techn. Bernhard Kronberger. We played a decisive role in co-financing the project through subsidies, and the project planning for implementation, including the formation of the project team, also bears the hallmarks of CONENGA Engineers.

Currently (August 2020), the planning phase for the numerous modifications to the equipment, assemblies, and automation is nearing completion. The next phase, the work on the construction site, is just starting, and the entire conversion will be carried out in an extremely short time window of three weeks of production downtime.

And then it gets exciting…

From the beginning of September, we will be leading the commissioning of the renewed and process-optimized plant. As CONENGA Engineers, we are not only ensuring stable, safe, and high-quality plant operation, but also pursuing the clear goal of helping STYROMAG become a pioneer in MgO production in Europe.

Further links

STYROMAG – Specialist in caustic-burned magnesite

Sources

Text: Excerpts from the KPC 2019 annual report

Image sources

- Cover image: STYROMAG

- Figure 1: CONENGA Engineers

- Figure 2: CONENGA Engineers