Soft sensors

Soft sensors

Soft sensors are an important building block for the process industry! With their innovative technology, soft sensors offer an effective solution for optimizing production processes and increasing product quality.

By using soft sensors, you can monitor your systems better, continuously analyze important process parameters and react to deviations at an early stage. This not only leads to greater efficiency and productivity, but also to improved product quality and cost savings.

The possible applications in the process industry are diverse and offer an effective, economical solution for optimizing production processes.

We are looking forward to answering your questions

Petra Steinmetz and Lukas Haffner are your experts concerning soft sensors!

WHY soft sensors?

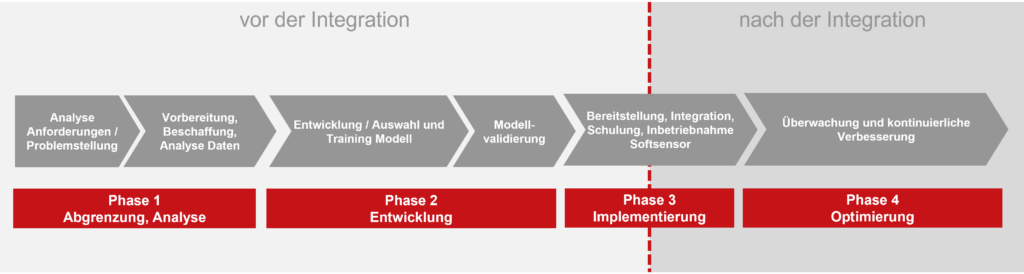

Whether temperature, quantities, masses, pressures, concentrations or other conditions – sensors provide the data required for automation and digitalization. Unfortunately, there is always a lack of basic data for evaluation or regulation. If, for example, physical measurements are not possible or only possible with great difficulty, or if there is no reliable measurement method, we use soft sensors.

What does a soft sensor do and when is it recommended?

Ultimately, a soft sensor provides a reliable online calculation from other, easily available measured values and corresponding software-based simulation of the physical relationship. It is therefore “a piece of know-how captured in software.”

To put it pragmatically: we calculate process values that we cannot measure but need for optimum control from available variables and the physical-process engineering context – online, in real time.

If sufficiently reliable variables are not available or the physical calculation cannot be replicated as a logical algorithm, we also use data-driven AI models as a tool. A soft sensor is therefore an important tool if a physical measurement (valid sensor) is not possible or too expensive. It is also used when existing, less reliable physical measurements need to be checked for plausibility or calibrated.

Examples from our field of application

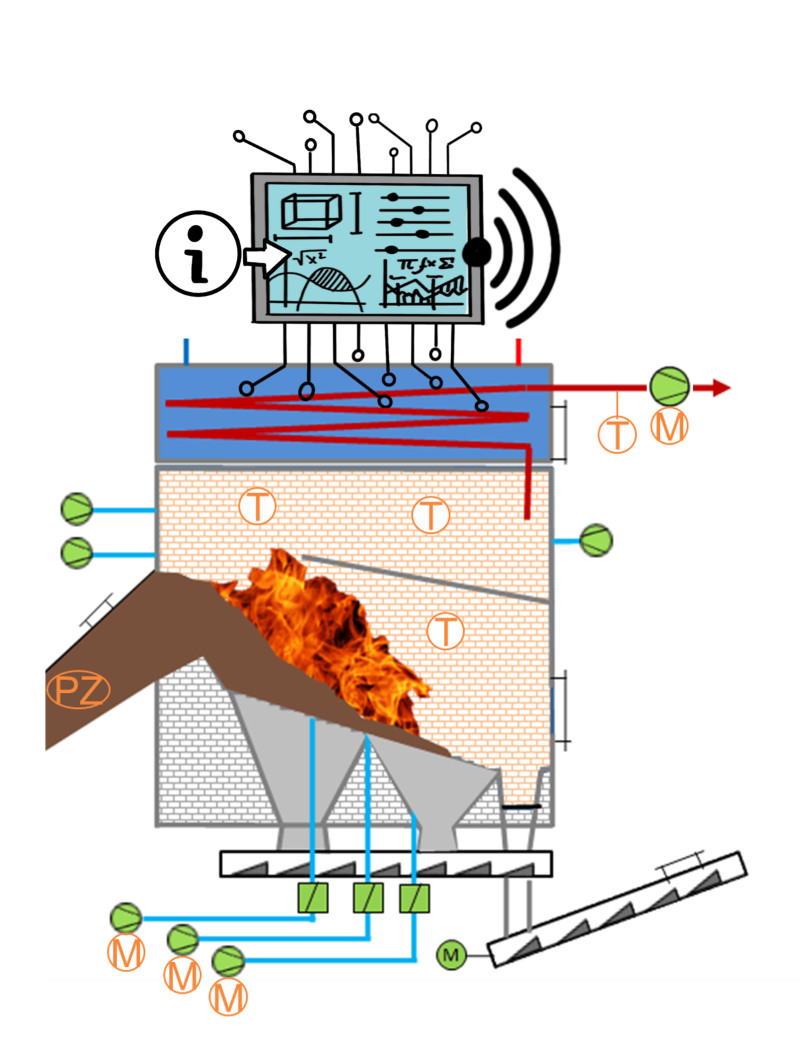

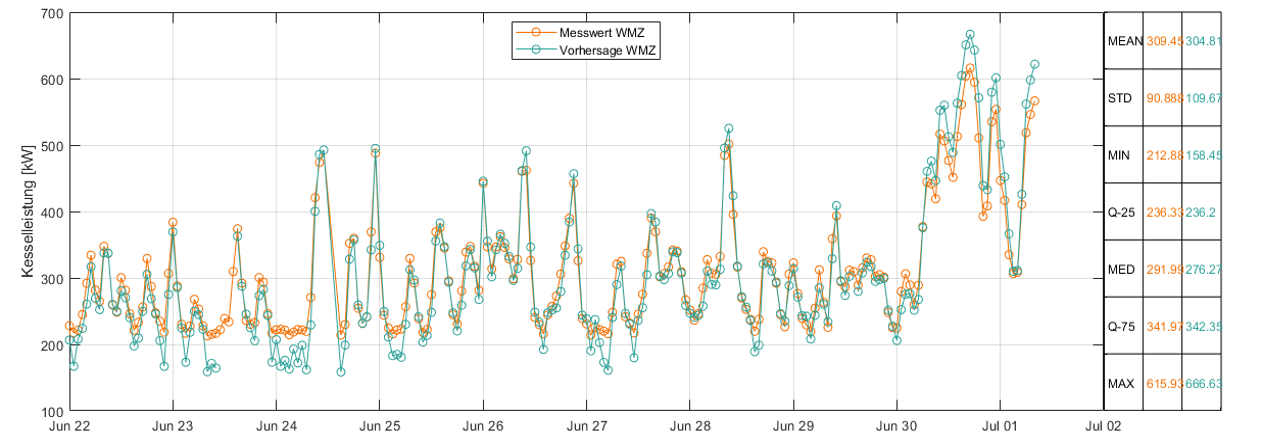

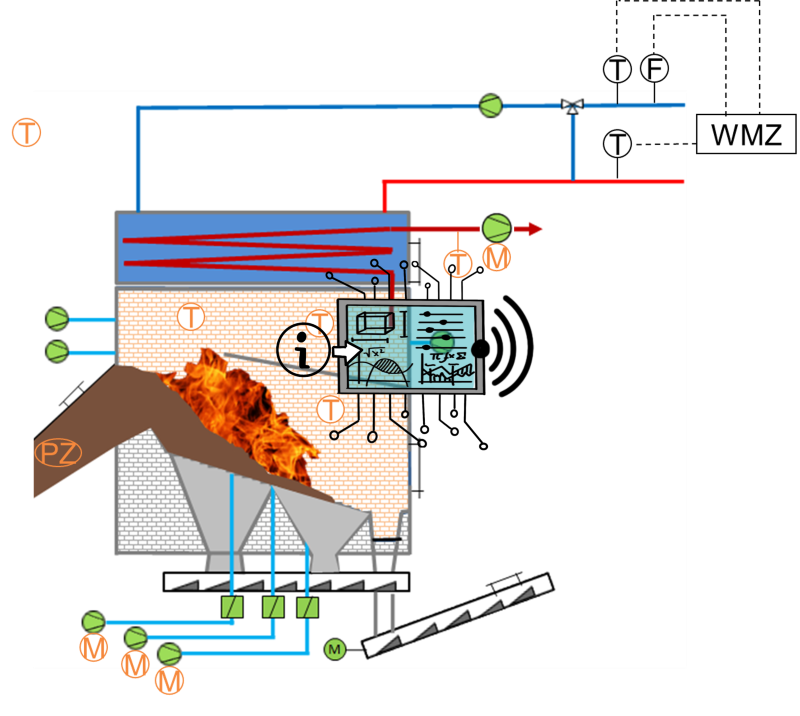

Soft sensors in combustion technology:

In combustion technology, we use soft sensors, for example, to calculate heat quantities, monitor O₂ measuring probes (drift) or detect the firing position in the stove.

For heat meters, we use a neural network with flue gas-based input data for validation and to bridge short outages.

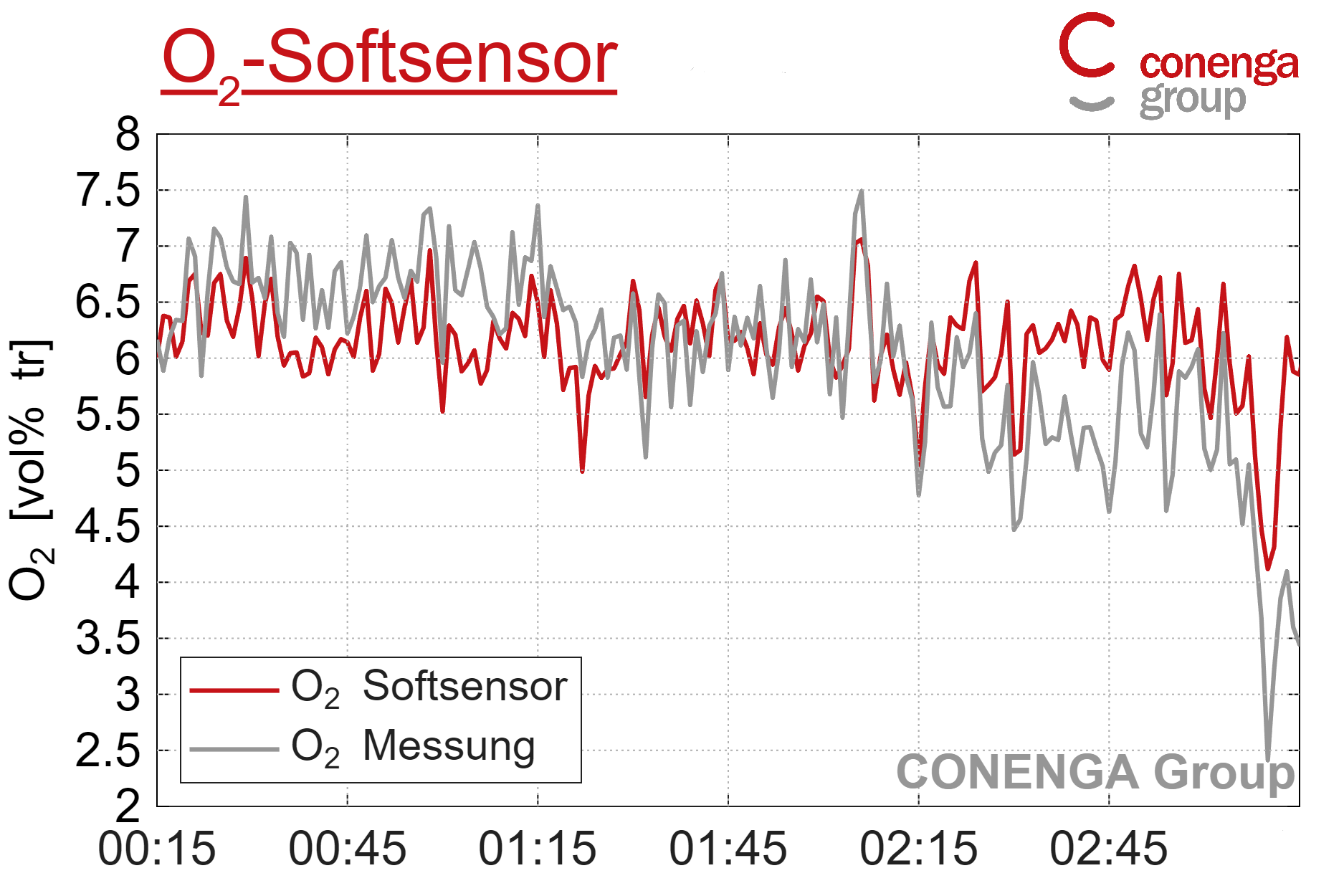

We also work with neural networks to provide the O₂ value as a central control variable for furnaces; the measurement drift of the physical O₂ sensor is recognized and can be corrected to increase efficiency.

For fire position detection, we use either temperature measurements via the course of the grate or the camera image.

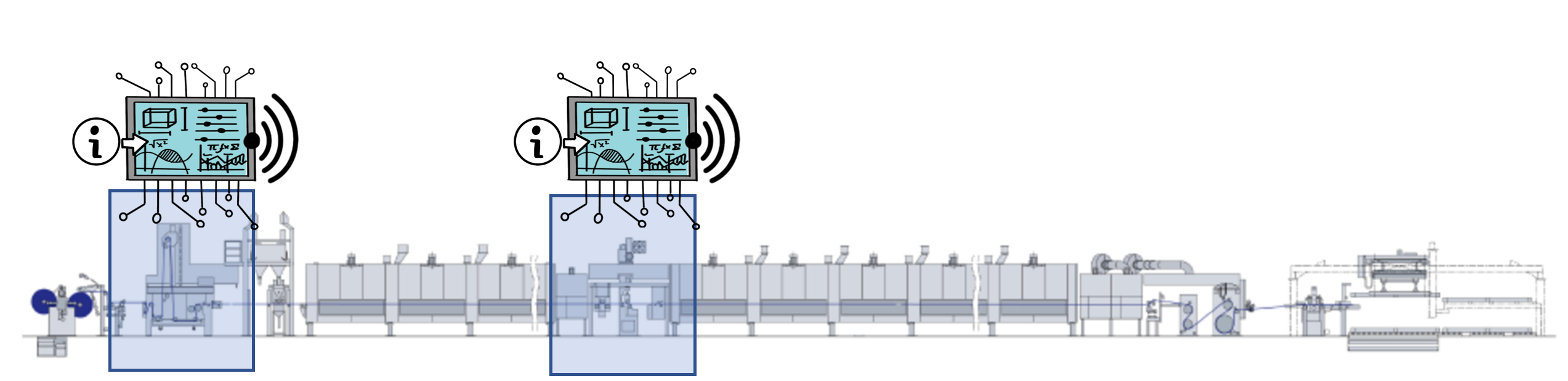

Soft sensors in continuous production – example impregnation channel:

For the impregnation of decor papers for coating laminates or wood-based materials, we use soft sensors to ensure the optimum resin ratio and ideal drying. With the resin ratio, for example, we use the weight changes of the storage containers and use these to adjust the channel. This simplifies the manufacturing process and has a positive effect on product quality.