Denitrification, SNCR systems

Denitrification, SNCR systems

Reliable & efficient: SNCR systems from CONENGA

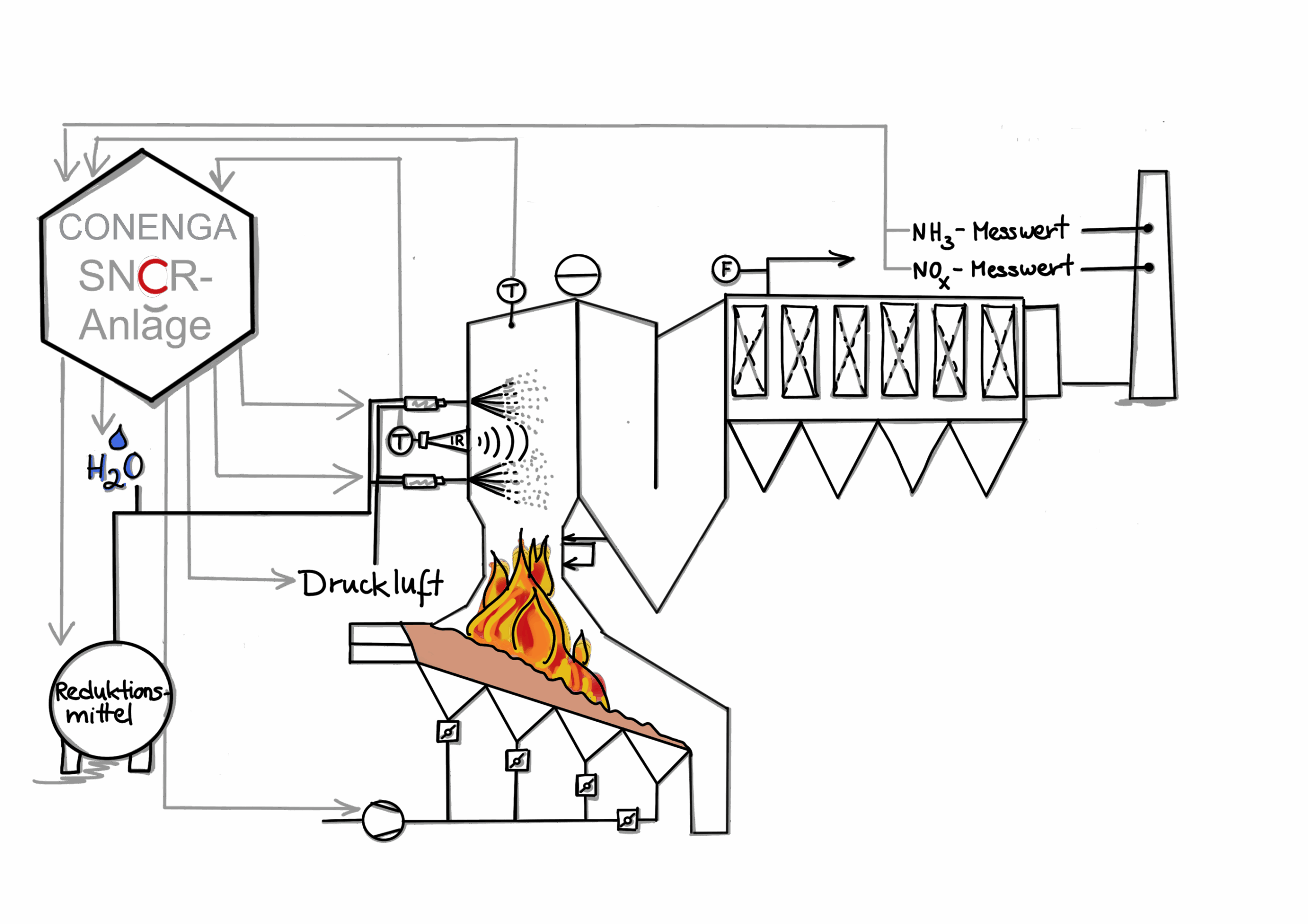

The SNCR process allows nitrogen oxides (NOx) to be removed from the exhaust gas efficiently and cost-effectively. Thanks to our many years of expertise in process and control technology, we can optimally design the SNCR technology for your system – and achieve a NOx reduction of up to 80 %.

Changing fuel qualities, dynamic load changes and stricter emission limits are a challenge for every combustion plant operator.

The SNCR control system developed by CONENGA ensures that your system reacts optimally to these changes at all times and achieves the highest NOx separation efficiency. Thanks to selective lance control, predictive NOx emission control, the use of soft sensors and dynamic NOx setpoint tracking, the emission limits are reliably complied with and operating costs are sustainably reduced.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am looking forward to answering your questions

Predictive NOx emission control

NOx emissions are only measured at the stack with a long delay – this often leads to inefficient dosing of the reducing agent. Our control system calculates the NOx value in real time on the basis of relevant process parameters and thus optimizes the amount of reducing agent in advance.

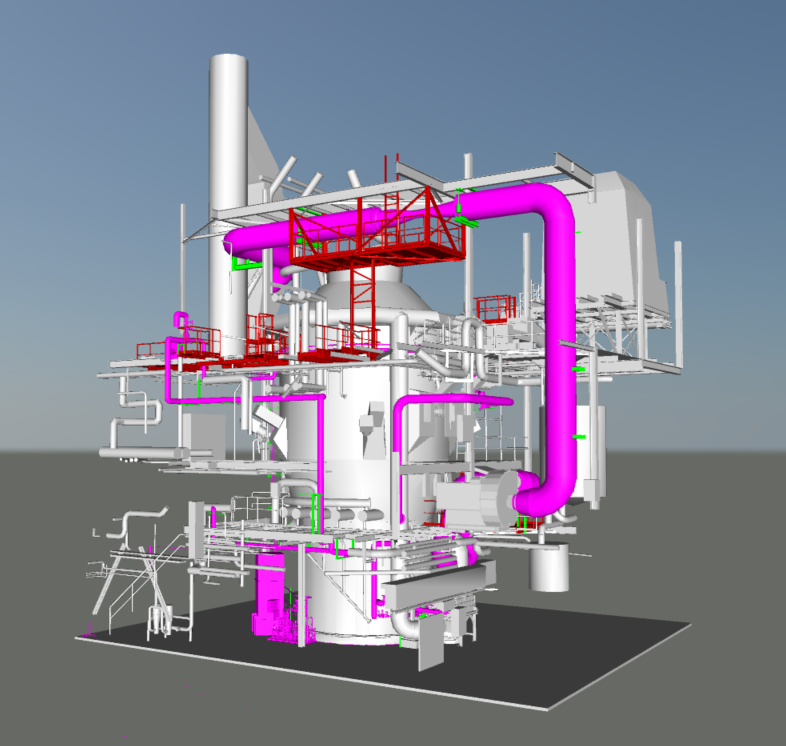

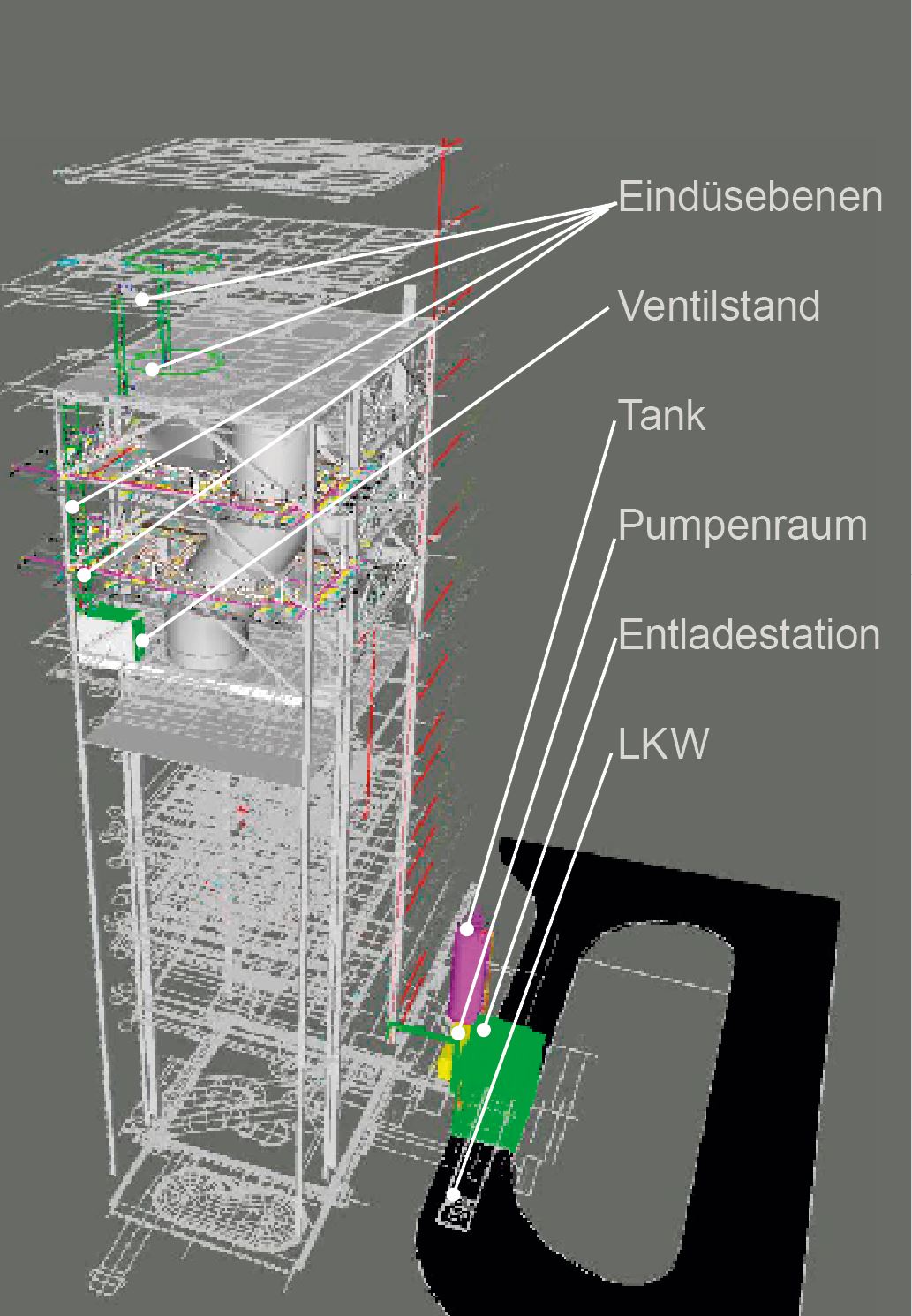

Soft sensor for maximum separation efficiency

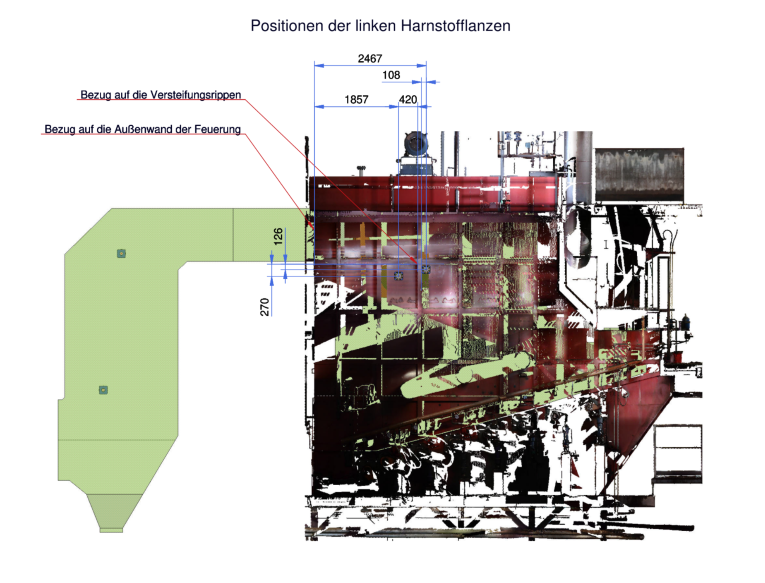

The optimum temperature window for the SNCR reaction shifts depending on the fuel and operating status. CONENGA’s soft sensor evaluates the efficiency of each individual nozzle lance and distributes the reducing agent specifically to where it has the best effect.

Dynamic NOx setpoint tracking

Process-related short-term emission peaks can cause limit values to be exceeded. Our intelligent control system reacts immediately, dynamically adjusts the NOx setpoint and ensures that the statutory half-hourly and daily limit values are always safely complied with.

System refit and optimization

Older firing and SNCR systems often no longer meet the stricter emission requirements. With the higher-level control concepts for SNCR and firing systems developed by CONENGA, we can make your system fit for the future again. We get the most out of your system with an intelligent combination of firing rate and SNCR control.

High reliability for safe emission compliance

Depending on the type of firing system and fuel used, an SNCR system is essential for compliance with statutory or official emission limits – which is why reliability and robustness are our top priorities. We only design durable systems that have proven themselves in practice over many years.

Continuous process monitoring

Our control technology solution integrates seamlessly into existing OT systems and enables continuous process monitoring thanks to a secure data connection via IT. Deviations and potential faults are detected at an early stage, and unexpected downtimes and operating resources are minimized. This leads to a long, worry-free service life for the system.

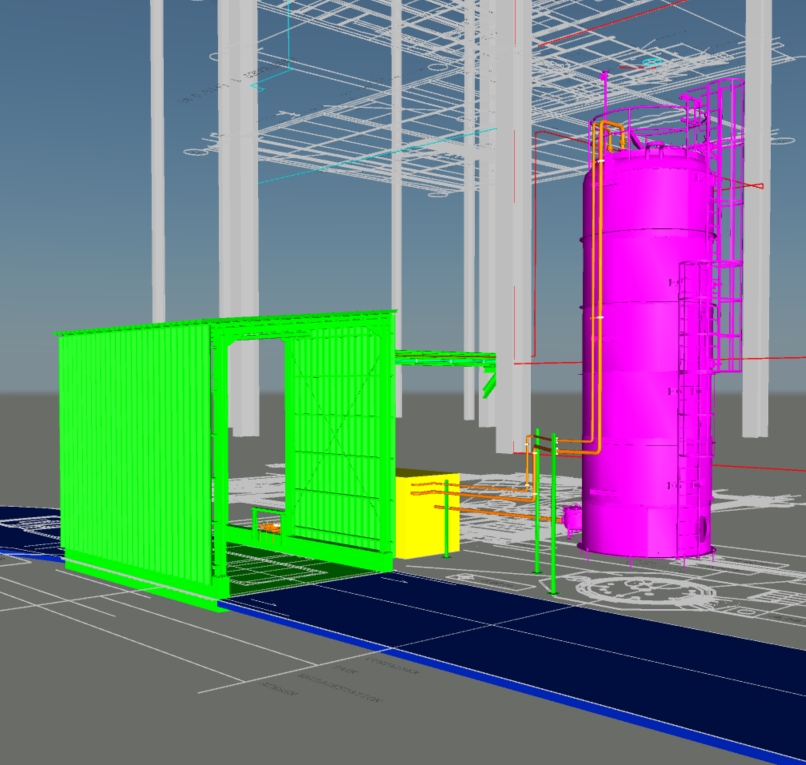

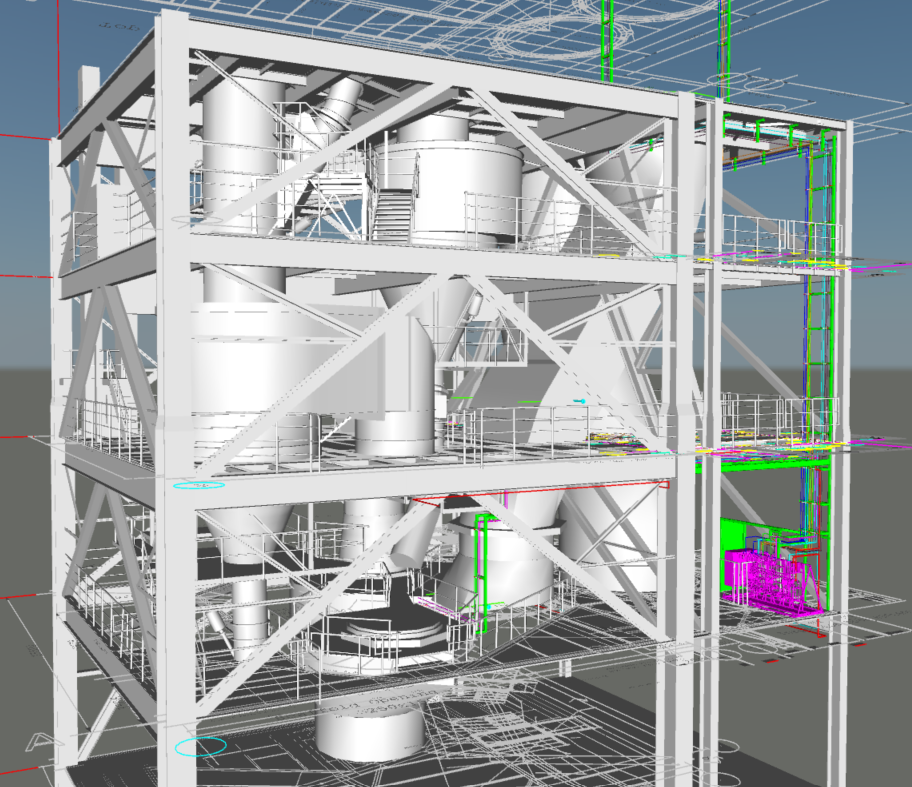

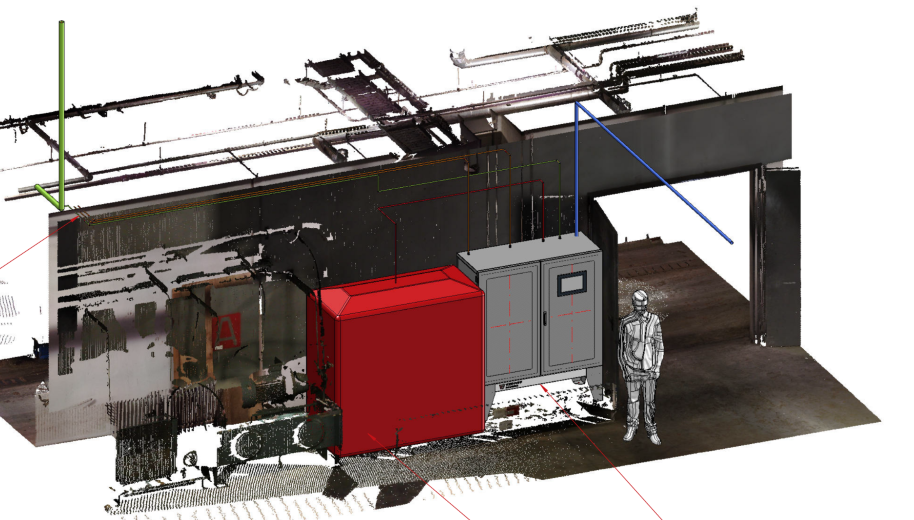

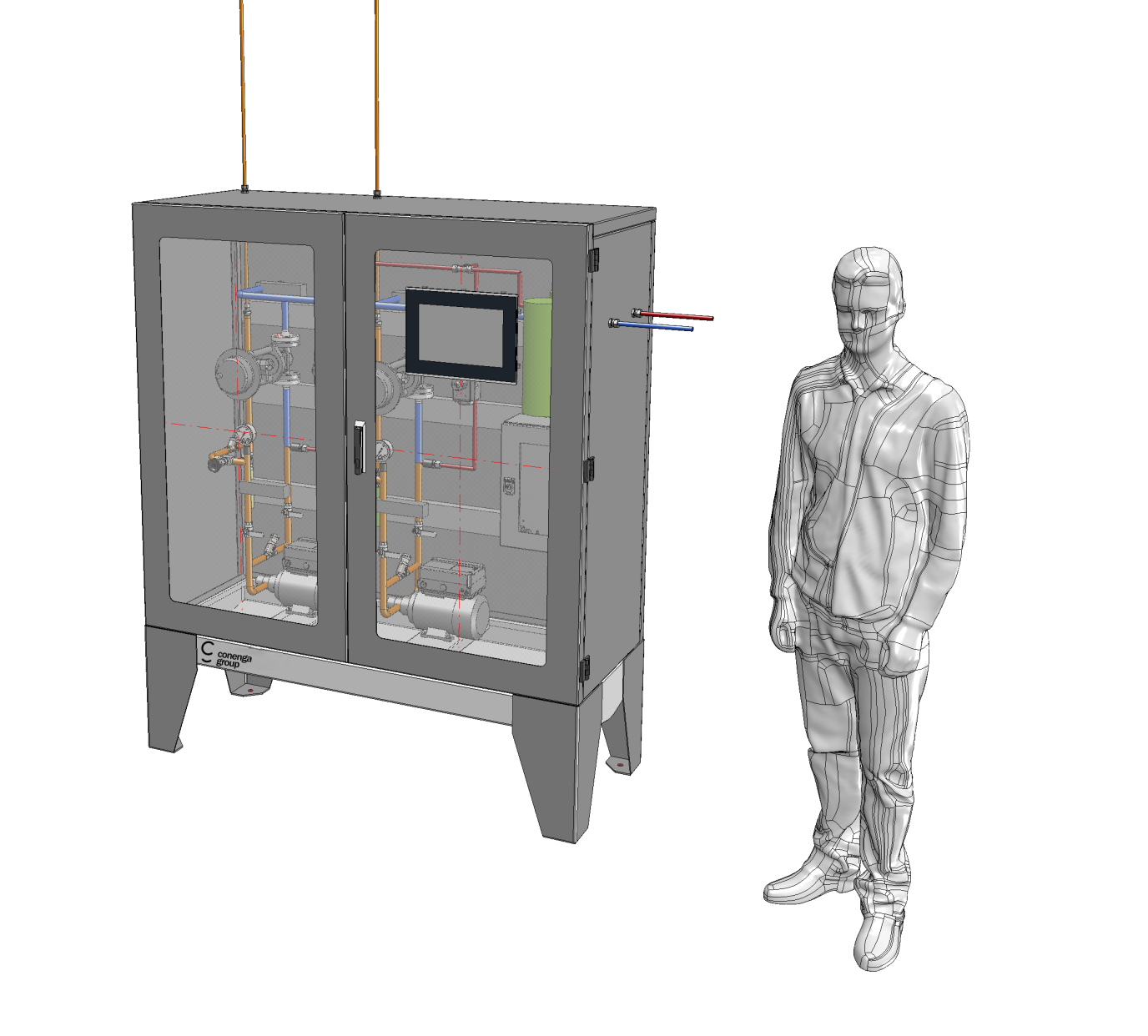

From a single source – turnkey SNCR systems from CONENGA

With the intelligent SNCR control system from CONENGA Group and our many years of process engineering expertise, we supply complete turnkey SNCR systems for grate firing, fluidized bed firing and rotary kiln systems as well as special processes from various industrial sectors.

- Complete turnkey solutions with CE marking – fewer project risks thanks to clear cost, time and quality control.

- Regulatory support included – we assist you with approval procedures, risk assessments and legal requirements.

Our services in detail:

Compliance with current and future emission limits is essential. We know what is important and analyze your circumstances: existing plant technology, the combustion process based on current process data, as well as the space available at the site – simply all the requirements and framework conditions to optimally configure the SNCR system. The performance limits are then precisely defined to avoid any surprises later on. This leads to the schedule and pricing for implementation. The result of the conception phase is a resilient concept for your custom-fit SNCR – clear in terms of technical, economic and scheduling aspects, as a decision-making basis for implementation.

From engineering to commissioning with comprehensive training, CONENGA Group is your one-stop shop. As experienced technology experts, we work with trusted partners to deliver the complete SNCR system as a tailor-made product at a fixed price.

Of course, CE certification for the overall service provided is just as much a matter of course as support with approval and testing procedures. We use our own proven digital technology for control and connection so that data on the system and operating states is available in a simple and user-friendly visual format. All in all, we thus live up to our claim of delivering SNCR as a turnkey product.

We support your interest in the economical operation and long-term value retention of your SNCR system and are available to you as a service partner throughout its service life. Coordinated with your own capacities, we support you in maintaining optimal operation. This is based on the service and maintenance plan for SNCR, which is included as part of the service package.

Thanks to comprehensive process monitoring, ongoing optimizations and adjustments to changing conditions, such as fuel changes or plant modifications, can be made. The consumption of reducing agents is continuously kept at the lowest possible level, and changes and malfunctions are detected at an early stage.

The system is designed for continuous operation and is therefore suitable for use in industrial plants and facilities. We contribute our extensive know-how on combustion technologies (grate firing, fluidized bed, rotary kiln) and the corresponding process engineering. Your plant remains “state of the art”.

The advantages of the SNCR process over the SCR process at a glance:

Key data for CONENGA SNCR systems:

| Reducing agent | Urea or ammonia water |

|---|---|

| Amount of reducing agent | 2 – 800 l/h |

| Separation efficiency | up to 80% |

| Number of nozzle | lances1 to 8 |

| NH3 slip | < 10 mg/Nm³ |

Customer testimonial:

“As part of the upgrade of our fluidized bed boiler by the experts from CONENGA, an SNCR system was also integrated. This not only enables us to remain below the emission limits, but has also proven to bestable and reliable in operation after more than a year of use. The SNCR control was implemented as part of the integrated EPOC suite.”

DI (FH) Bernhard Pichler, Project Manager, NORSKE SKOG