Simulations

Simulations

Shaping technology for the future together!

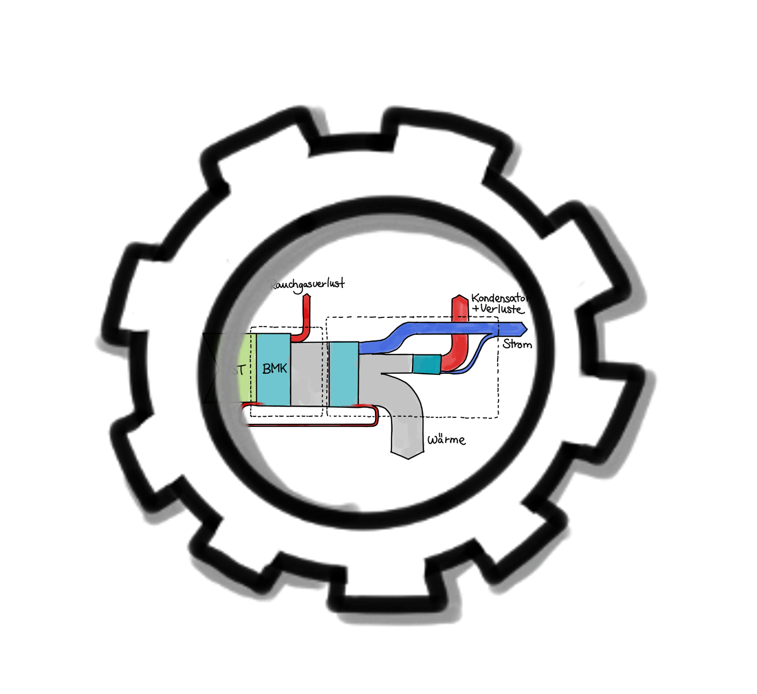

When considering and planning the construction or conversion of new process plants, questions always arise regarding plant performance and environmental impact (e.g. CO₂ footprint). We carry out facility simulations to provide reliable answers to these questions and those relating to fuel yield or emission behaviour.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am looking forward to answering your questions

Lukas Haffner is your expert concerning simulations

We simulate the planned system configuration and system states as well as the control behavior, particularly during normal load changes during operation and in the event of faults. This enables us to accurately predict whether effectiveness and efficiency are guaranteed for the existing concept and whether critical situations will occur or how the system will then behave.

In optimization projects or capacity expansions, we also eliminate ambiguities with regard to the expected performance by means of dynamic simulation.

Our consistently systematic approach is based on handling large amounts of data and guarantees meaningful results in terms of the problem and beyond. As a client, as well as a contractor, you can confidently implement and commission an optimization after a successful simulation.

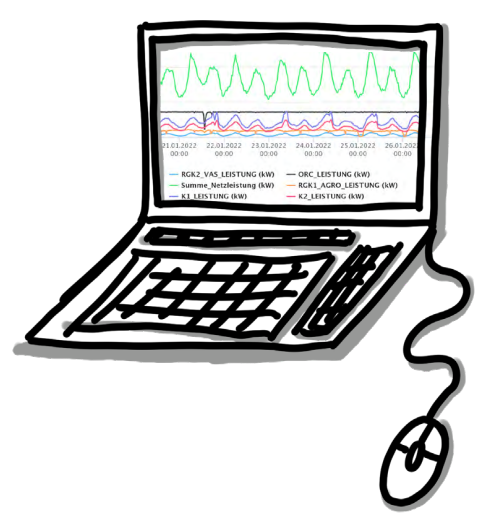

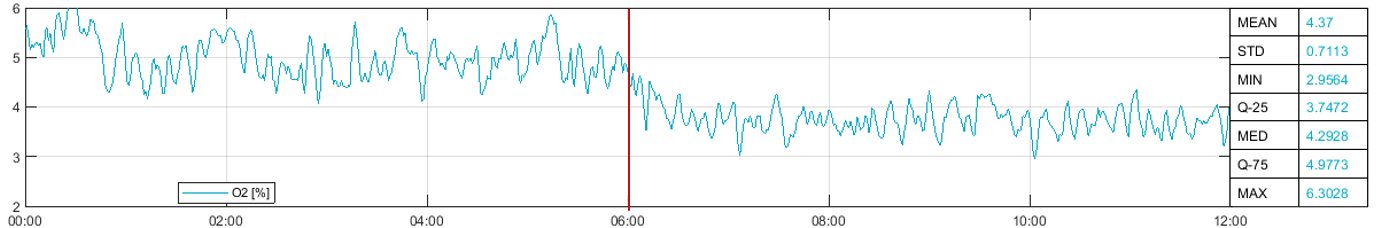

The following example shows the simulation of the O₂ concentration – at 6:00 a switchover is made to the control to be tested.

Regardless of whether you already have specific issues to address or just started idea phase or concept development – we are happy to support you in an initial exchange. We look forward to hearing from you!