Fire position detection

Fire position detection

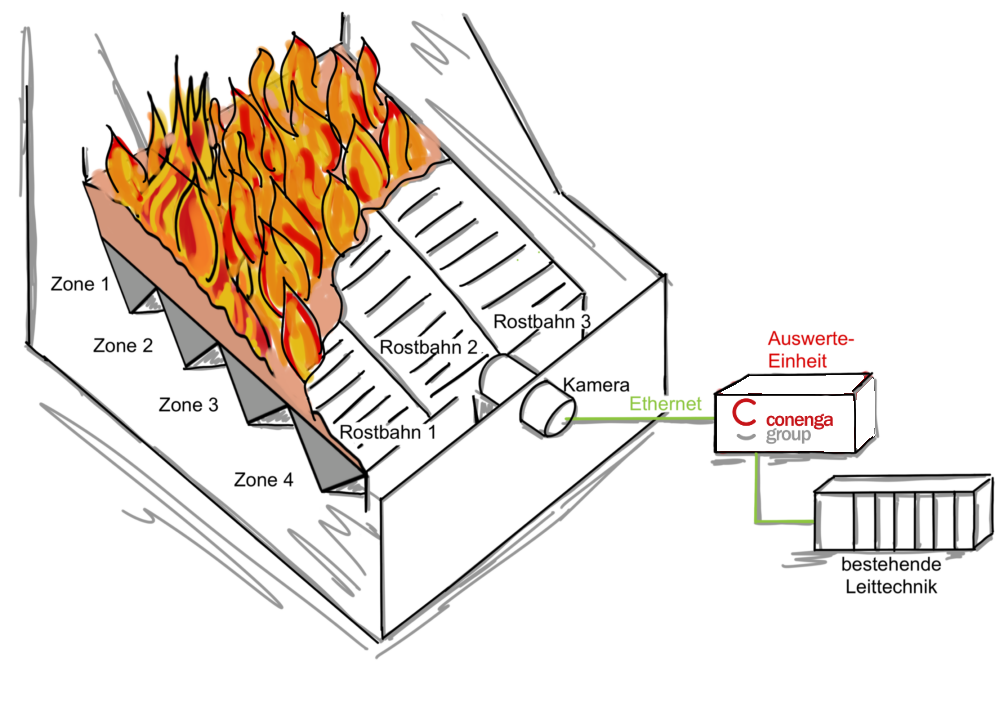

The fire position detection system developed at CONENGA Group enables you to digitally determine the current fire position in grate firing systems. This can serve as the basis for significantly improved control of the combustion process. In addition, automatic anomaly detection and fault forecasts can contribute to stable power plant operation and extended travel times.

Digital information on the current fire situation

Our AI models, implemented with neural networks, independently evaluate the individual images of an optical firebox camera and extract important information, such as the position of the fire location or the length of the burnout zone (=burnout reserve). With this information, which is provided in digital form, it is possible to integrate the fire situation into the control concept. This allows continuous optimization of the combustion process. Burnout reserves are detected and adjustments can be made to grate speeds and material feed. This allows you to make the most of your existing grate area and achieve a smoother firing position.

You can access the data via an open interface, which we can also integrate directly into your control system. With this access to the history data, it is possible to draw conclusions about the fuel, among other things. Provided that performance values are included, other analyses such as correlations to fire position can also be performed.

Our fire position detection system impresses with its comparatively low costs, as it is based on an optical camera instead of the significantly more expensive infrared cameras and can often make use of existing cameras.

Your benefit

-

AI-based detection of the position of the firing position and the length of the burnout zone

-

Integration into existing control technology as well as availability of open interface

-

Recognizing correlations between combustion parameters and fire position

-

Optical camera with digital signal as low requirement

-

24/7 data acquisition as the basis for alarming

Our process engineers start by analysing the circumstances and physical conditions in order to ensure the greatest possible optimization of the system with our firing position detection.

Prerequisites

Fire position detection requires image material of the entire combustion chamber from a fixed combustion chamber camera with RTSP support. Operation with multiple firebox cameras is also possible. If this requirement is not met or if you wish to retrofit, we will be happy to support you in choosing the right camera for your system, using tried and tested industrial cameras.

The right IT infrastructure is also required for optimum and secure use of the data. We provide the required IT infrastructure and offer a cloud solution or a combination of cloud and on-premises solution depending on your requirements. We design the IT infrastructure in close coordination with your IT security rules and your IT department.

After delivery and commissioning of the combustion chamber camera (if not yet available) and the required IT infrastructure, an initial data set optimized for your combustion chamber is generated, which we use to train an optimal AI model for the specific characteristics of your fire position determination.

The trained AI model is then integrated. This includes data recording, data exchange (e.g. via MQTT) and optional integration into your SCADA system as well as control. It goes without saying that we contribute our extensive expertise in grate firing and the corresponding process technology.

Once trial operation is complete, we work with your technicians to transfer the installed solution to regular operation.

Other services

Thanks to the secure digital connection, we can adapt, retrain and optimize the software as required, for example to ensure the functionality of the fire position detection in the event of a component change, a combustion chamber conversion or a fuel change.

Combination with products

For your optimum benefit from automatic firing position determination, we use our EPOC® Boiler or BCS® FLR firing rate controls. With AI-based fire position detection, we improve existing process engineering controls and ensure permanently improved boiler operation.

I am looking forward to answering your questions

Sebastian Sturm is your expert concerning fire position detection

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

Further information: