Facility balance

Facility balance

Facility balance: Shaping technology for the future together!

Do you have a challenging problem that requires process engineering expertise, creativity and the ability to innovate? You are looking for a competent development and implementation partner for your concept?

We design a model to simulate different load cases and system configurations in order to process the system balancing using process simulation. We compare the resulting energy balances according to the specifications and technical evaluation criteria (e.g. from the EU taxonomy).

Would you like to find out more about Facility Balance? Should we call you or would you like to receive further information by e-mail?

We are looking forward to answering your questions

We are your experts concerning system balancing and innovations

We create the necessary simulation models using the IPSEpro (SimTech) process simulation software, for example. With IPSEpro, it is possible to efficiently calculate mass, energy and energy balances for process plants or plant components and to correlate various process parameters or illustrate the dependencies.

Material data for water, ideal gases, organic substances, solids, etc. as well as common components (pumps, compressors, heat exchangers, reactors, valves, etc.) are available in a model library or are developed if necessary. By combining these, it is possible to simulate complex processes at different levels of detail.

Facility Balance: Our services

The input data is provided by the customer. Seasons are taken into account as required. This enables the simulation of summer and winter operating conditions with a supplementary profitability analysis.

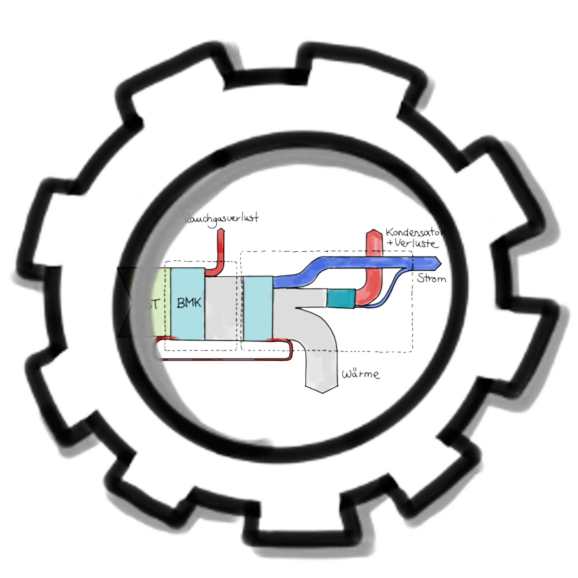

The simulation model to be designed takes into account the existing relevant generation, conversion and consumption plants within the system boundaries under consideration. We simulate the load cases to be considered from the actual configuration or the desired configuration.

Typical input data for power plants

- Fuel compositions and heat outputs

- Steam mass flows in the form of produced steam, (un)converted steam and steam required for consumers

- thermal and electrical outputs or own consumption

- (maximum) generator outputs

- Further facility data such as efficiency, pipe dimensions and limits regarding flow rates, outputs, etc.

- specific marginal costs for the calculation of specific operating costs

Usual results of Facility balance

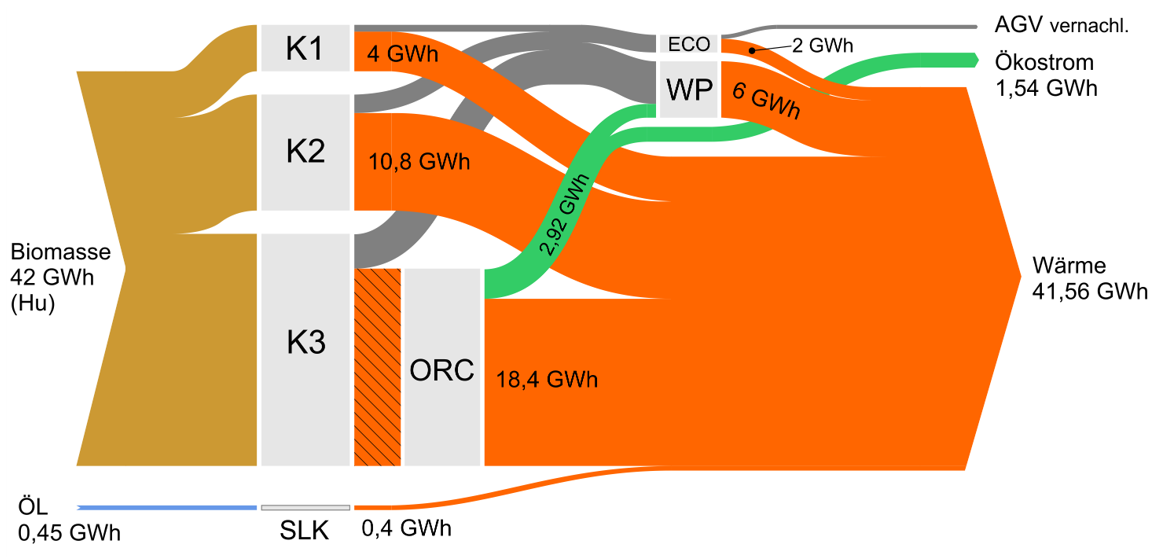

We present the results of the process simulation using selected load cases. These include cost diagrams (cost and revenue shares, cost difference summer to winter operation in percent), steam mass flow diagrams and an overall picture as Sankey diagrams, in which the thickness of the bars or flows reflects the outputs.

Regardless of whether you already have concrete ideas or are still in the idea phase or concept development – we are happy to support you in an initial exchange. We look forward to hearing from you!

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?