Artificial Intelligence

Artificial Intelligence

Process data has been determined and recorded since the beginning of industrial plant automation. We apply artificial intelligence methods, in particular machine and deep learning, to create data-driven models from your operating data. These fulfill a variety of application purposes, support your employees in operation and increase the efficiency of your system in a comprehensible way.

Conventional approaches do not provide a sufficient solution for your issues? Do you need support in predicting developments or recognizing unusual conditions? Our expertise in the field of machine learning assists you to break new ground.

Let’s work together to find a solution!

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am looking forward to answering your questions

Petra Steinmetz is your expert concerning artificial intelligence

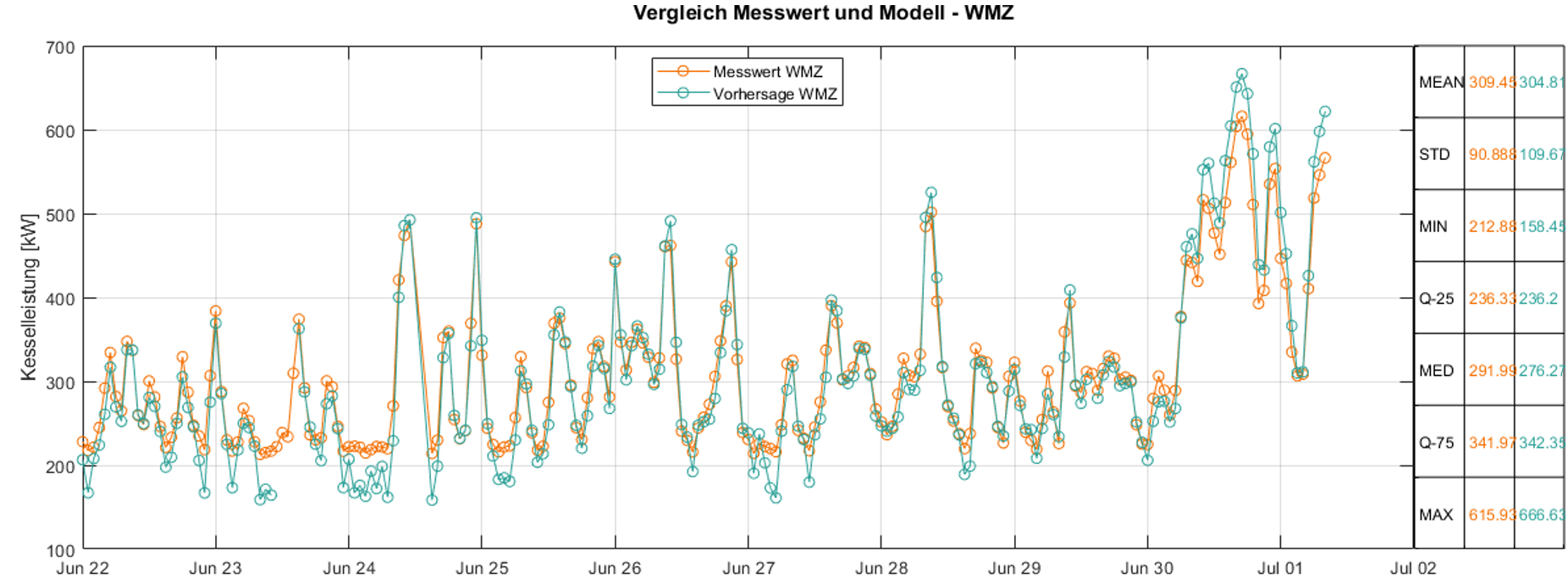

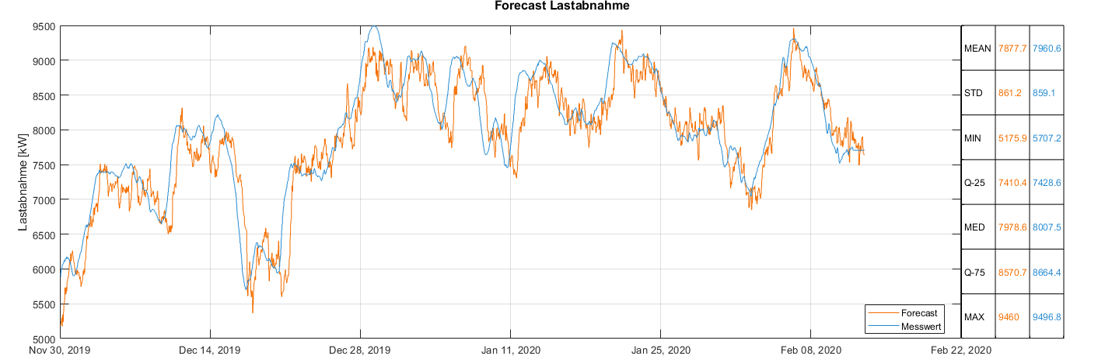

Case study prediction of power consumption

The primary request to district heating networks is to ensure compliance with the energy demand at any time. As biomass boilers are often unable to react quickly enough to fluctuations in demand and peak loads, a peak load boiler with fossil fuels input is usually operated to meet the demand – a cost-intensive solution, which is related to high emissions. A combination of an appropriate control and buffer storage tank enables quick and reliable responses on changing heat demands. At CONENGA Group, we use neural networks to predict the future heat consumption of your district heating networks. The specifically adapted model uses historical data and other parameters (e.g. outside temperature) for calculating the expected change in performance. This prediction enables you to optimize the use of the buffer storage tank and reduce the operating time of the peak load boiler. In addition, your biomass boiler will operate more consistently and quietly.

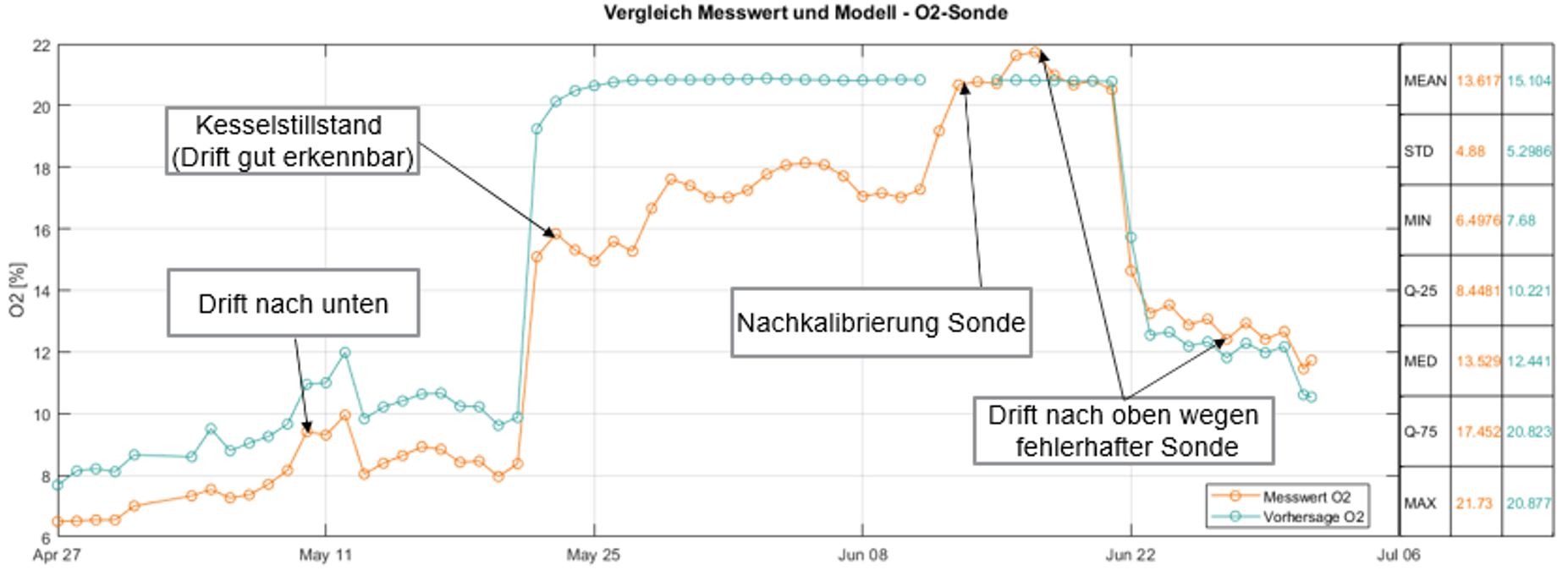

Case study measured value validation

The validation of measured values is essential to ensure the efficient operation of an automated system. Sensor failures and incorrect measured values lead to suboptimal control and therefore inefficiency. Artificial intelligence enables the validation of measured values without the use of additional hardware eg redundant sensors.

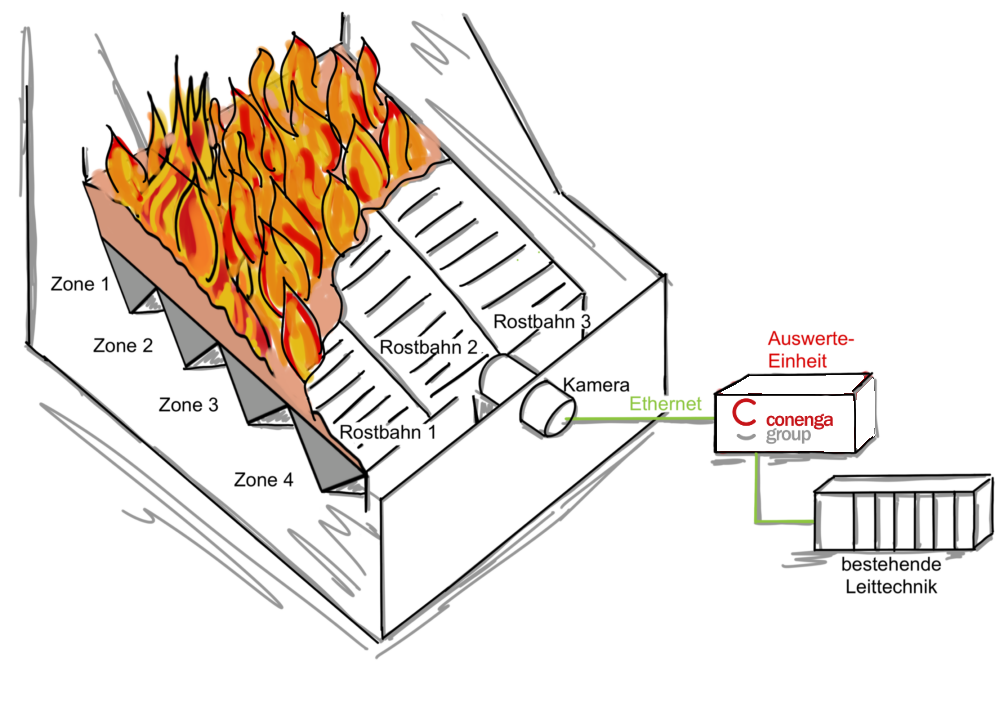

An artificial intelligence-based regression model developed by the CONENGA Group is used, for example, to validate the measured value of an O₂ probe. As the residual oxygen content provides the most important information for combustion control, any reliable automated correction of an incorrect measured value (eg due to a drifting sensor) poses a substantial simplification. Accordingly, the correction of an incorrect measured value – for example due to a drifting sensor – is of great importance.

Furthermore, we rely on a neuronal network to calculate the boiler output, which is trained solely on data obtained from the flue gas (independent from the water side). Hence, influences from brief failures of the heat meter are overcome and it is possible to validate the sensor output value.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?