Flue gas cleaning

Shaping technology for the future together!

Our innovative flue gas cleaning solutions offer an effective and sustainable method of minimizing the use of operating materials such as lime additives or activated coke in your plants. Using our customized approaches, we can increase the efficiency of your plant and at the same time reduce the quantities of cost-intensive residual materials such as filter ash that need to be disposed of.

Our expertise in the field of flue gas cleaning enables us to develop individual solutions for your system. We attach particular importance to close cooperation with our customers in order to achieve the best possible result. We are at your side as a partner – from the initial analysis and development of a tailor-made concept through to implementation and optimization.

Whether optimizing existing systems or developing completely new solutions – we have the experience and know-how to meet your requirements.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Bernhard Kronberger is your expert when it comes to flue gas cleaning!

Our services at a glance:

- Analysis of the status: examination of the system and emission limit values

- Data analysis: evaluation and interpretation of relevant data

- Concept development: Development of customized solutions

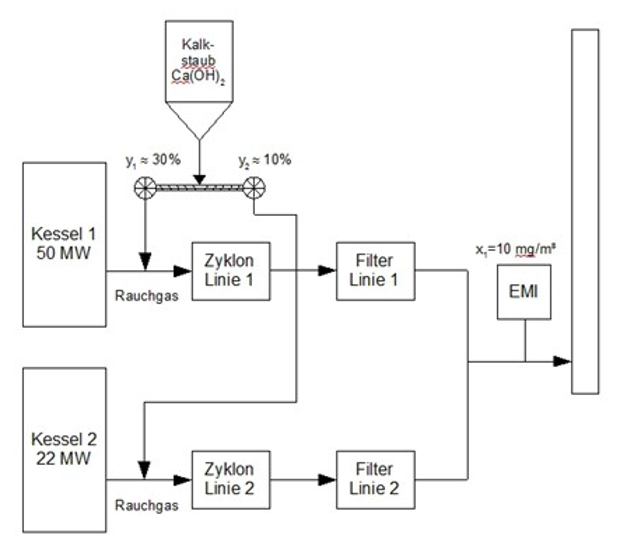

Example of a sorption process

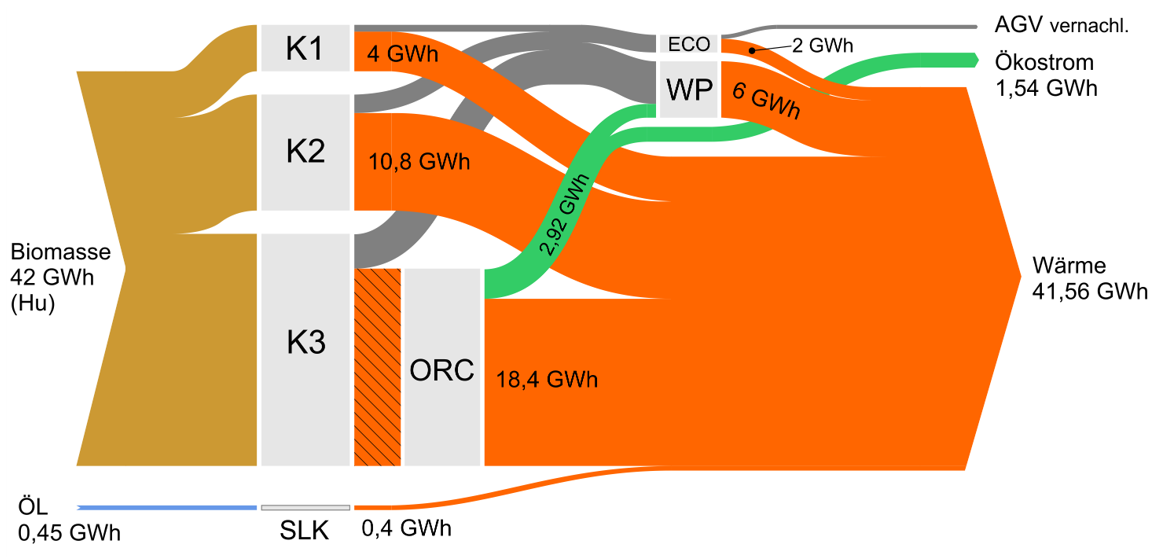

Our example plant consists of two combustion lines, a common storage tank for the absorbent Ca(OH)2 and a common HCl measurement at the stack. The aim in this example is not to exceed the legal requirement of 10 mg/m³ HCl in the flue gas while at the same time minimizing the total lime input.

We achieve this goal by using advanced model equations for HCl adsorption, which are mapped in a special control algorithm. This algorithm calculates the loading (in g-HCl per g-lime) based on the HCl concentration in the flue gas. Our system takes into account all process-related influencing factors in order to maximize lime adsorption.

In this way, we keep the total amount of lime used and the disposal costs as low as possible.

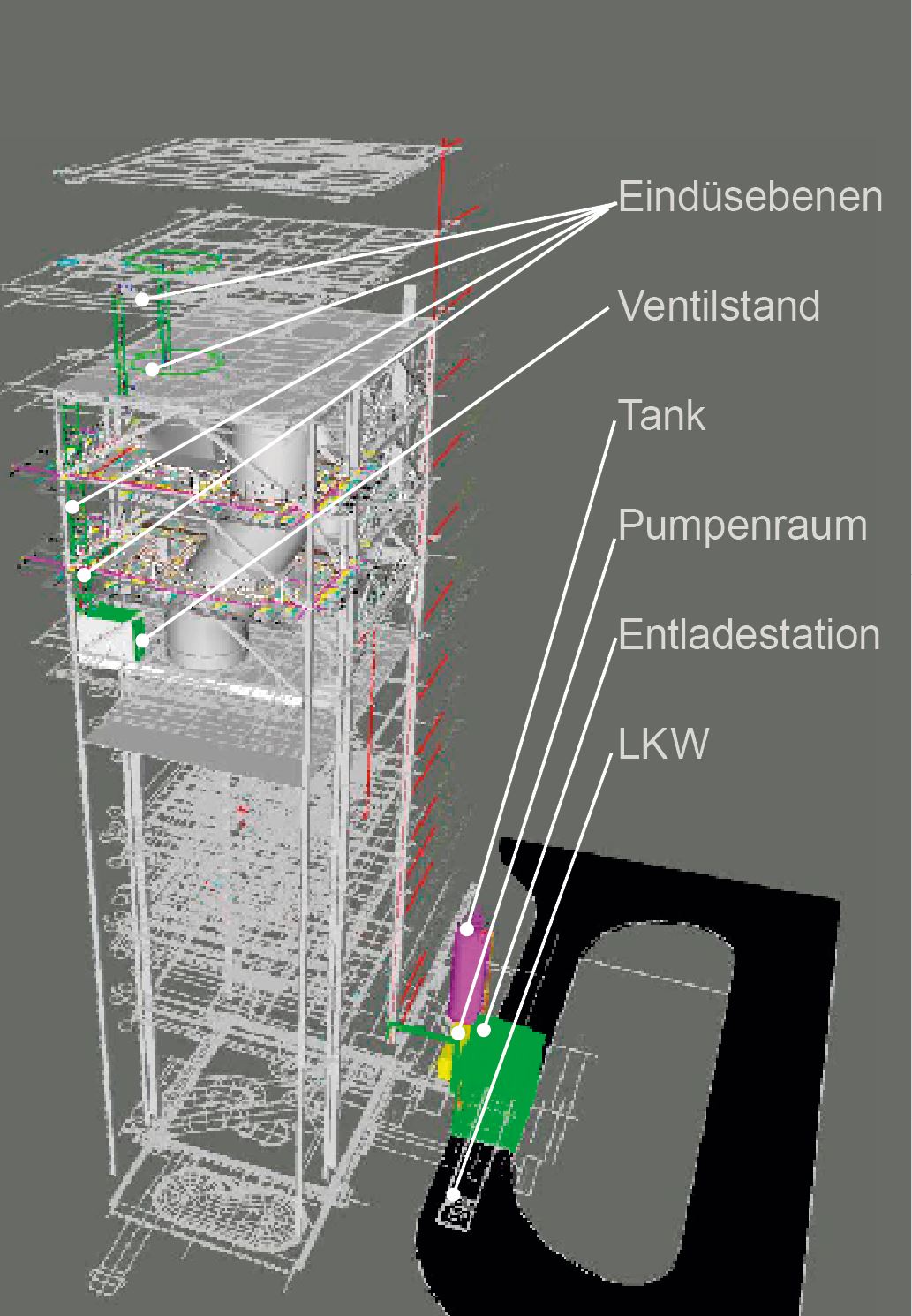

Dedusting

Dedusting is an essential part of flue gas cleaning in waste wood and waste incineration plants as well as in industrial dedusting. We have extensive expertise in the design, control and optimization of these systems.

Our goals include minimizing operating costs and maximizing travel times for key technologies such as fabric filters or multi-cyclones. By optimising these plants, clean exhaust air and thus optimal environmental protection is achieved.

For the dedusting of combustion exhaust gases, it can make sense to optimize the degree of dust separation instead of minimizing it in order to improve the residual material disposal routes. The purity of the exhaust gases always remains the top priority.

Methods used

- Mass and energy balancing: determination of energy and material flows

- Comparison of key figures: benchmarking and performance analysis

- CFD analysis (Computational Fluid Dynamics) as a basis for flow optimization (together with scientific cooperation partners)

Optimisation measures

- Conception, basic and detail engineering of conversion measures

- Cyclone design based on the laws of fluid mechanics

- Use of baffles and flow equalizers to improve flow control

- Support in selecting the optimum filter media