Flow optimization

Flow optimisation

Shaping technology for the future together!

We know that flow optimization is important for the maximum efficiency of process engineering systems. By using state-of-the-art CFD (Computational Fluid Dynamics) simulations, we can develop precise solutions that make your systems more efficient and economical. Our expertise and commitment are aimed at finding the best possible solution together with you. Rely on our experience and expertise to optimize your processes and reduce costs in the long term.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

I am happy to be there for you!

Bernhard Kronberger is your expert when it comes to flow optimization!

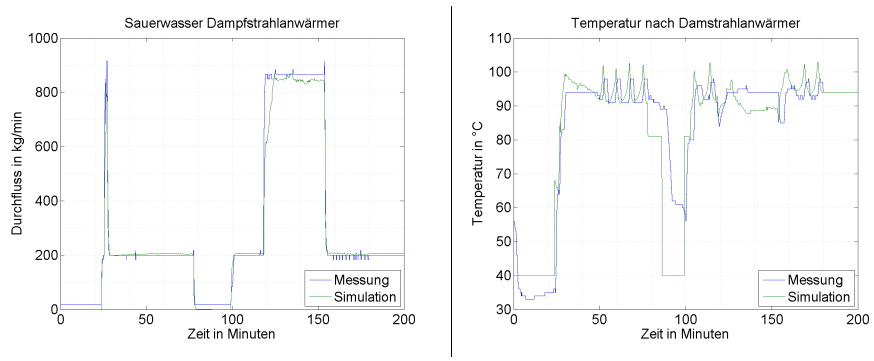

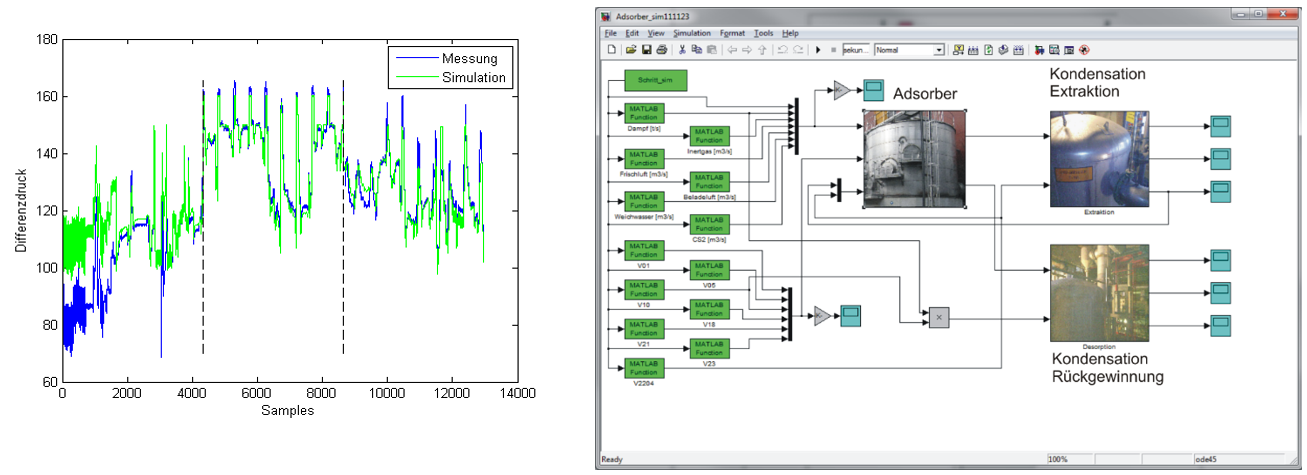

Possible results you receive from us after flow optimisation

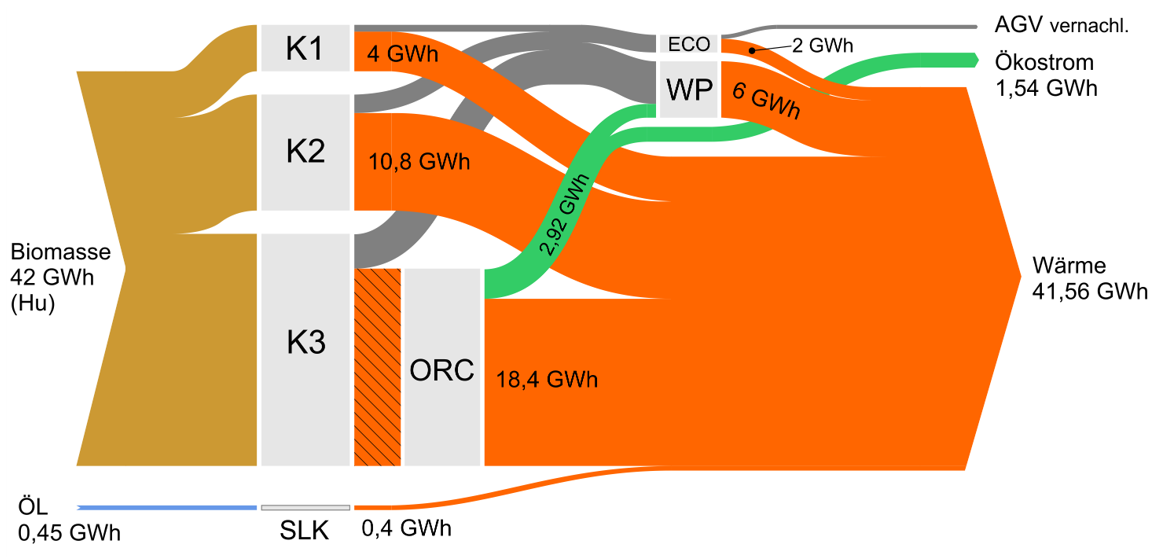

- Analysis and optimisation of the incident flow of the heat exchangers (CFD analyses, baffles, etc.) for improved utilisation of the installed heat exchanger surface area

- Analysis and concept to avoid corrosion on the heat exchanger surfaces

- Lower pressure losses and therefore lower power consumption of the fans/pumps

- Analysis and concepts for increasing the heat recovery rate and thus reducing fuel costs in the case of heat recovery systems.

The picture below shows a heat exchanger surface with an unfavourable incident flow and thus poor utilisation of the installed surface. If the inflow is very different, damage to your system or individual parts will occur much more often and faster. Up to a third of the usable flue gas energy is often not utilized. This prolongs the amortisation of the system and increases the risk of premature damage.

Regardless of whether you already have concrete ideas or are still in the idea phase or concept development – we are happy to support you in an initial exchange. We look forward to hearing from you!