Dryer systems

We are familiar with a wide range of process engineering challenges for different types of dryers and in specific industries.

You benefit from this wealth of experience in combined process and control engineering optimization. The customized control concept gets the maximum out of your dryer systems, usually leading to smoother and therefore more robust operation with consistently high energy efficiency, quality and performance of the drying process.

Your advantages at a glance

- High energy efficiency, corresponding economic efficiency

- Quiet, robust operation

- Constant product quality

- Emissions within the limit values

- High degree of automation

- Transparent KPIs

Our extensive experience from many implemented projects is integrated into our EPOC Dryer product.

Would you like to find out more? Should we call you or would you like to receive further information by e-mail?

We are here for you!

Dominik Gappmaier & Bernhard Kronberger are your experts when it comes to dryer systems!

Dryer-specific design levers

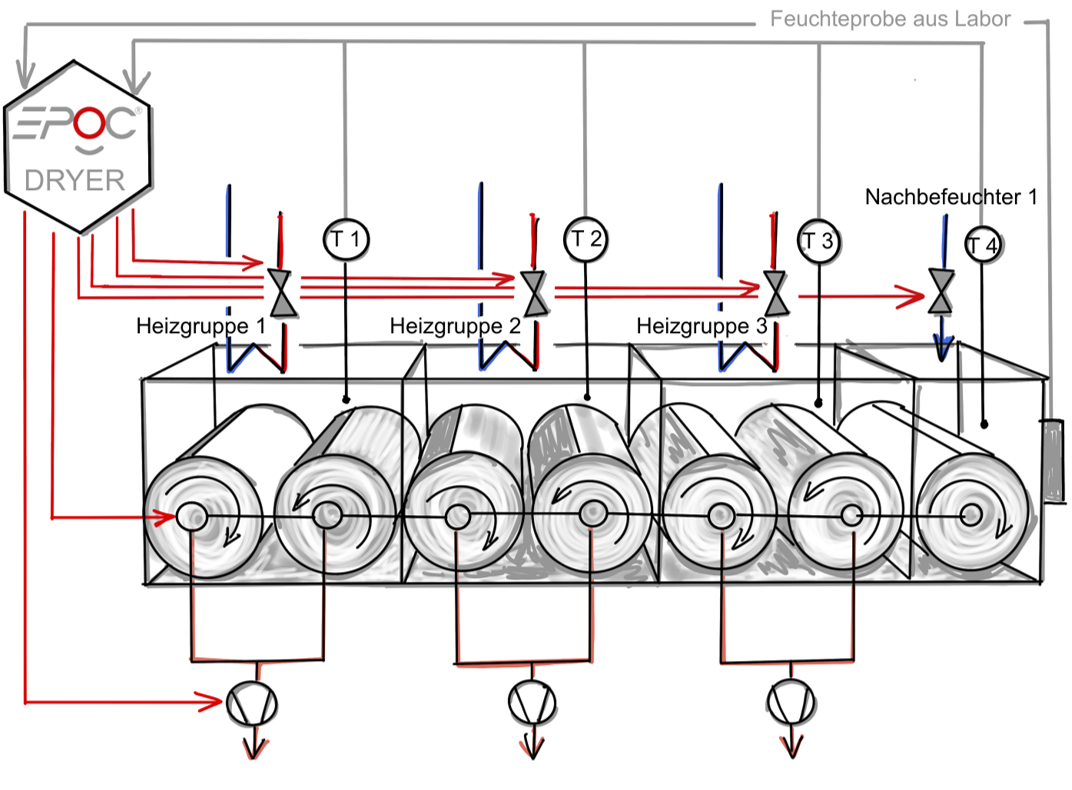

Indirectly heated drum dryers

-

- Shortening

the start-up times of a dryer after standstill (rapid achievement of a stable operating state, e.g. for chip feeding)

the start-up times of a dryer after standstill (rapid achievement of a stable operating state, e.g. for chip feeding) - Stable discharge of condensate from the tube bundles

- Good material transport in the drying drum

- Optimum drying air recirculation with centre extraction

- Automatic optimisation (minimisation) of specific energy consumption for chip drying

- Avoidance of oscillations of the exhaust air temperature

- Avoidance of chip supply shutdowns due to “dryer clogging

- Shortening

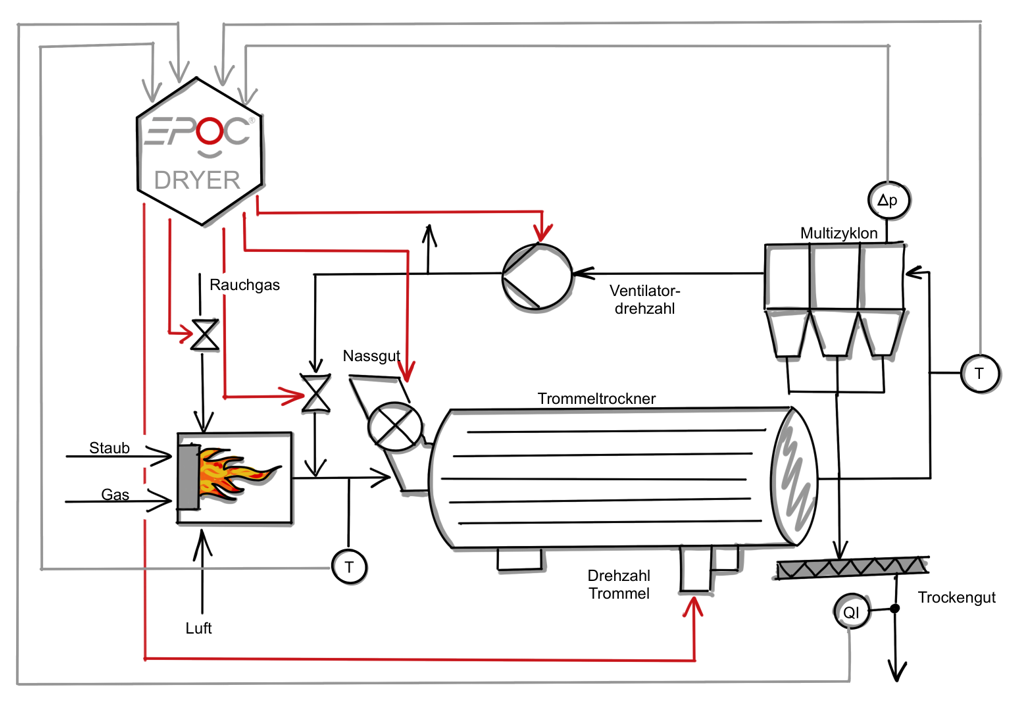

Directly heated drum dryers

-

- Optimum process control with and without exhaust air recirculation for energy-efficient operation through optimum saturation of the drying gas

- Optimum loading and temperature of the extract air, taking into account the humidity balance (sorption isotherms)

- Good material transport in the drum

Trough-air drying (screen drum and belt dryers)

-

- Minimisation of the specific drying energy requirement

- Optimum throughput

- Minimisation of start-up times

- Minimisation of rejects during start-up and in the event of malfunctions

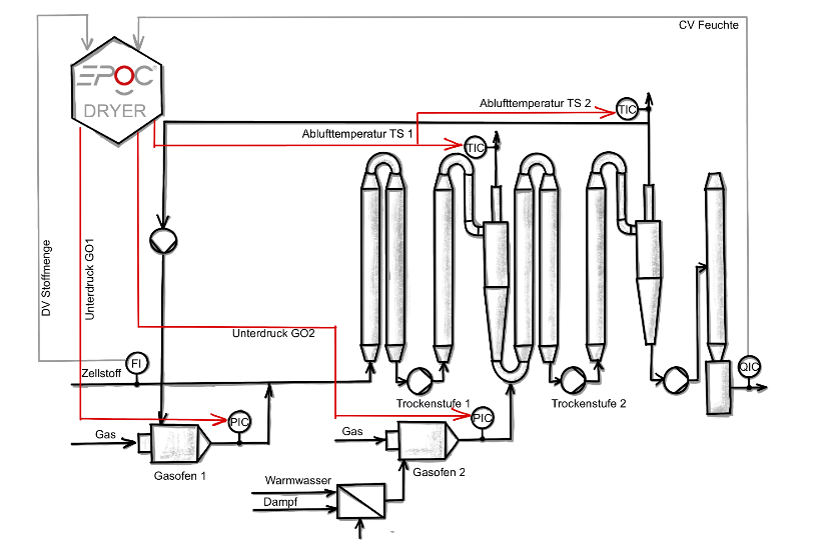

Airstream dryer

-

- Optimum energy distribution with 2-stage drying

- Maximum recirculation of drying air by regulating the negative pressure

- Regulation of exhaust air temperatures, thus optimum saturation of the drying air

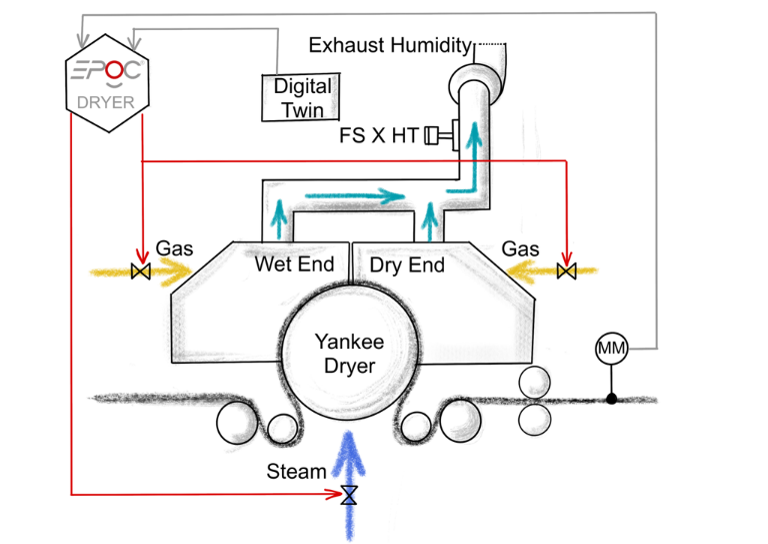

Dryers of paper and coating machines

-

- Fast automatic ramp-up after tear-off and standstill from performance speed to maximum target speed – especially for “light” products (low grammage)

- Maximizing the target speed while maintaining the highest product quality, especially for “heavy” products (high

grammage)

grammage) - Minimisation of grammage change waste by accelerating grammage changes

- Automatic provision of optimised tear-off/feed cylinder parameters

- Maximum quality with high energy efficiency

- Automatic detection and visualisation of the maximum speed, taking into account the condition of the line

- Visualisation of limiting factors

Depending on the technology, we use the basic levers mentioned above in our combined process and control optimisation.