NEW WORK – Came to stay!

“New Work” is a buzzword that is not so new anymore, but has come to stay – and to retire the previous system “work”. After two years of the pandemic at the latest, a large part of our society has arrived in the global-digital age, which has completely new demands on our jobs, employers and their image. Aber was versteht man eigentlich unter New Work?

Read the full article here

FACT Consulting: Self-Management – Deductions from Agile Software Development

We are all challenged, times are demanding and constantly bring new challenges. You can reward yourself and your team once in a while and do something good for yourself. All the better if this also boosts the organization as a whole. That’s exactly what we offer with our interactive online webinar “Self-Management”.

In four eventful hours we set impulses for self-reflection and common exchange. Organizational learning included. Curious about it? In the Following a short foretaste of the subject areas!

Finally “saying no” – and thus being able to delimit and focus

Here, the first exciting learning opportunities from the field of agile software development are already being raised: For example, if individual work orders are not clearly defined, or cannot be fulfilled at all, they can and should be rejected. This is what gives the rules of the game their practical meaning. This approach – quite natural in agile software development – is experienced as uncooperative or disruptive in many organizational cultures and must first be practiced and established accordingly.

We pass on the relevant practical tips and experience – because “saying no diplomatically” in order to ultimately achieve goals more quickly has to be learned.

Dräng dich nicht – Mit Stresssymptomen konstruktiv umgehen

Here, findings from brain research stimulate discussion: Humans are creatures of habit and so our “reptilian brain” takes over when stressed and overrules our intellect or cerebral cortex. For this, new, positive experiences and good feelings are needed to be able to turn off the “learned highway” onto new paths.

In the training you have the opportunity to reflect on your personal stress management and to expand your coping options accordingly with helpful tools. Unhelpful behavior under stress becomes evident, more suitable variants are added – and you find it easier to deal with yourself and regain agility!

With changes in personal stress management, the balance between mind, body, and emotion must be established and appropriately useful as a resource. Positive feedback on the new ways of thinking and behaving promotes their anchoring in one’s own actions.

Fail Elegantly – The Crisis as an Opportunity for Successful Learning

In agile software development, somewhat simplified, the potential for failure is narrowed down to the hours worked in a development sprint. If these do not bring the expected customer benefits, adjustments are made or the procedure is changed in the so-called retrospective (i.e. the feedback round after each sprint) according to the motto “inspect & adapt”.

This again relates to the stress management already discussed – while a sprint is being implemented, no heckling from outside is allowed and the team can fully focus on the content work. This promotes stability and eliminates “non-productive” unrest from the team.

Long-time “followers” of the EFQM excellence approach can also see parallels here with criterion 2 – organizational culture and leadership – which in excellent companies refers to the organization as a whole.

Are you ready?

- Read enough to give yourself and your team a half-day of “self-management” before heading into the stressful fall?

- Have you always wanted to get to the bottom of your “favorite stressors” and leverage them?

- When it comes to “saying NO,” have you thought of two or three staff members who would support purposeful reflection?

Of course, it’s the right mix for your organization that makes the difference! Contact us and together we will design your customized webinar and bring your team the decisive step further. Because those who manage themselves more effectively are automatically more successful in their dealings with others.

I am happy to collaborate with you!

With autumnal greetings, yours Johann Sauermann

PS: We communicate in our webinars via MS teams and also use an electronic whiteboard. This allows interactive work and the results are documented in a comprehensible way – this has proven very successful in practice. We can also use your individual company software.

CONENGA Group: Project controlling has a name!

Is your glass really full?

Who doesn’t know them. The motivational story of the glass with the pebbles, the sand and the water. The large stones are filled into the jar until it is full. Following this, you are asked whether the glass is now full. Yes, it is. Now small pebbles are added to it. Is the glass full now? Yes, isn’t it? Stop! There’s still something there. Now sand is filled, it slides through the stones and fills all the gaps. But it’s full now, isn’t it? No. Water is emptied into the glass in a vivid manner. What do we learn from this? The order of filling is crucial. If you fill small pebbles to the brim first, no more large stones will fit.

Converted to project life, it might mean that there is still some space between the big orders – the big stones – and the small orders – the small stones, and  by clever and foresighted planning and layering, the glass can still be filled.

by clever and foresighted planning and layering, the glass can still be filled.

Project controlling is therefore more than “juggling numbers”. It is a successful support of the project managers in the project execution.

Identify needs

But everything from the very beginning. In order to layer our “glass” in the best way possible, we naturally also need someone in our company who can keep an eye on the project. As an important and essential building block for project management along the corporate strategy and as support for the project manager, it is imperative for us. Especially as CONENGA Group in the diverse project work in the areas of management consulting, technical consulting, process and control engineering solutions as well as plant (re)construction, it was necessary to strengthen ourselves in project controlling in order to optimally fill the now quite large glass.

Wie finden?

For recruiting, we relied on DIY recruiting and a personalized job ad, as we had for past job postings. The joy was immense, because this time it worked again faster than expected through “informal” channels! The recommendation of a colleague was a stroke of luck and we were able to welcome Anja Trnka to our team. “War for Talent” won!

Project controlling – achieving results with consistency and communication

As a mom of 2 kids and a lot of experience in the legal field, I know that planning, structuring, and staying “on top of things” are key.

This helps me to manage my main tasks of keeping an economic overview of the projects and reporting to the management at regular intervals. Are you a customer or partner of ours? Then maybe we have heard, or read about each other?! I am happy to be able to act as an interface between project managers and customers and thus contribute to good cooperation and sustainable satisfaction.

In my view, the importance of project controlling is reflected in the following topics:

Project controlling – short and crisp

Even before the actual start of the project, project controlling comes into effect with various tasks

- Are the targets and framework realistic? Targets can then be adjusted as needed

- Identify potential problems at an early stage and make them visible

- Optimized process planning

When it’s on and afterwards

During the project, the focus is on:

- Meeting deadlines and budget

- Control

- Condensation of the results and recording of deviations from the target status

- Accompanying reporting and project closure

What’s it like for you?

Who is responsible for tasks such as budgeting projects, ensuring that all project goals are met, supporting bid costing, performance tracking, or customer-side billing? Do you have anyone responsible for managing both contractor and delivery requirements, analyzing and, if necessary, modifying measure planning and controlling measures, etc.?

If not, remember the jar of stones! :-) Project controlling is multifaceted and more than just “monitoring or controlling” a project.

A contribution by Anja Trnka and Melanie Schwarz

VOIGT+WIPP: Bad point control – Intelligent solution for biomass cogeneration plants

The bad point control is an intelligent solution package for biomass CHP plants to operate district heat pumps in the optimal efficiency field while minimizing grid losses and electricity costs. Every heat customer in a district heating network requires a pressure difference between the flow and the return at its transfer point to the district heating network in order to ensure a sufficient supply of heat. The pressure difference is guaranteed by the pumps of the district heating network.

The control of the speed of these pumps can be different. Even though speed control today is practically always via frequency inverters, this does not automatically mean that maximum energy efficiency is guaranteed.

Classic variant

Simple, but not very efficient is the control to the differential pressure in the boiler house. The differential pressure can still be varied on a sliding basis according to flow rate or power reduction. It is preferable to calculate the required differential pressure from the pipe network characteristic curve of the district heating network and to transfer this setpoint to the controller for the network pumps. Nevertheless, there is also a risk of under-supply here, which is why a safety factor must be included, which in turn leads to increased pump power consumption.

Effizienteste Variante

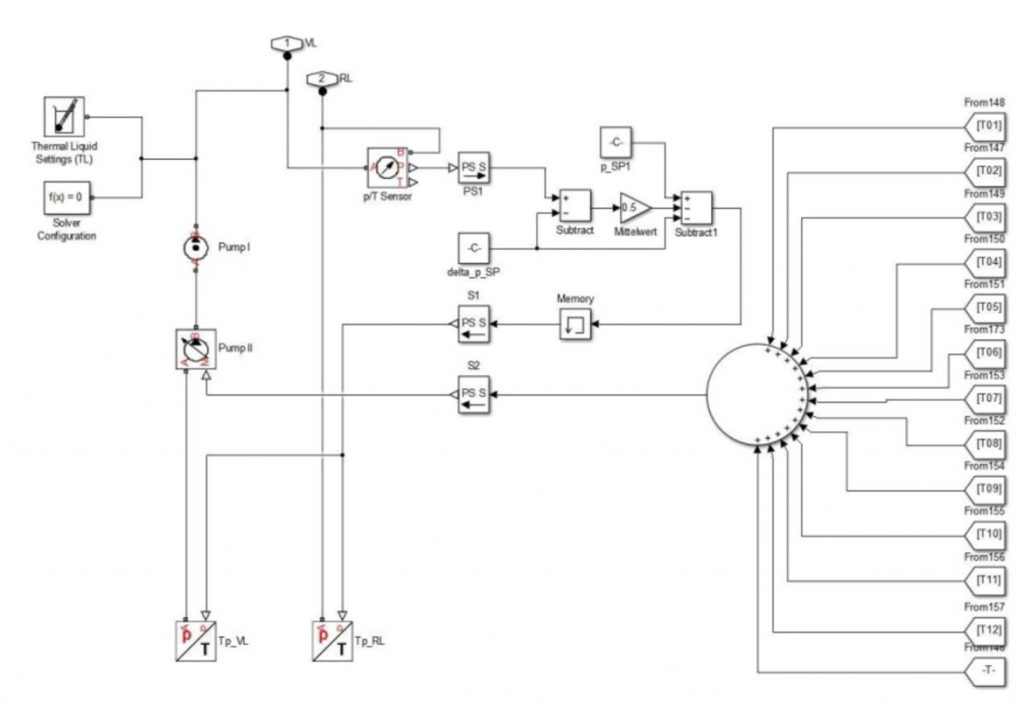

In order to always operate the network pumps at the optimum efficiency level between guaranteed heat supply and maximum energy efficiency, it is necessary to use all available information from the district heating network and the pumps. Based on the two variants above, the efficiency map of the pumps in use is also stored as a model. This adds an essential function to the controller, enabling intelligent pump management in addition to bad point control on pressure differential.

The VOIGT+WIPP Engineers Solution

This functionality is integrated in our BCS (Biomass Control Solution) Suite in the modules BCS-FWM (district heating management) and BCS-SPR (bad point control) in perfect interaction. This guarantees maximum efficiency in the heat supply, which also includes the minimum heat loss of the pipeline. The so-called “network losses”, as only as much water as necessary is pumped through the district heating network.

This system can also be ideally applied to large district heating networks with several pumping stations, as these can communicate with each other and thus react simultaneously to pressure differences in the district heating network.

Simulation model for pump management and pipe network characteristic curve (modeling FWN)

Steps to the most efficient variant

First, the current “bad points” in the district heating network must be identified. This can be done empirically or calculated from detailed piping diagrams. If changes to the district heating network are planned in the medium term, the bad points may be shifted. In this case, it makes sense to install several bad point measurements.

The differential pressure is transmitted to the heating plant via a GSM connection if no other transmission is possible or economical. Due to the wireless transmission of the information, the bad point measurement can be offset with less effort. This advantage becomes important in district heating networks that are continuously extended or modified by ring connections. In order to be informed about the current status of the bad points and the pump condition, this information is made available to the user via a web-based visualization. If a signal failure occurs between the bad point and the heating plant, the system switches automatically and without jumps to a fallback solution on the PLC, which is directly responsible for the setpoint specification of the district heating pumps.

Advantages of the bad point control for plant operators

- The bad point and pump management modules can be implemented quickly and flexibly

- The number of bad points in the district heating network can be flexibly adjusted as required without the need to stop operations.

- Efficient operation can reduce the power consumption of the district heating network pumps by up to 15 % – while at the same time optimizing supply and failure safety and reducing heat losses.

Reference project Holzwärme Altenmarkt

VOIGT+WIPP was commissioned by Holzwärme Altenmarkt to carry out an energy check for production plants promoted by Umwelt Service Salzburg. In the course of this energy check, the district heating network and the control of the network pumps were analyzed.

„The power consumption of the mains pumps could be reduced and the plant operation could be improved considerably by the bad point control optimized by the company VOIGT+WIPP Engineers, in which the operation of the four mains pumps in the Altenmarkt CHP plant was optimized by the integration of 3 redundant bad points. Through the cooperation with VOIGT+WIPP, we feel well equipped to master the future challenges for a technically as well as economically optimal generation and distribution of environmentally friendly heat for our customers in the best possible way.”

Ing. Günther Seifter, GF Holzwärme Altenmarkt GmbH

Everything from one source

In addition to special topics, such as bad point control, we are also experts in higher-level control systems and have developed the BCS suite, a complete control technology solution package specifically for biomass cogeneration plants. This consists of various modules that are installed on existing systems.

The control system docks onto existing automation and safety processes without changing or influencing them. Such modern control algorithms avoid costly conversion work as well as associated plant shutdowns.

VOIGT+WIPP Energy & Environment: Einblick Projekt Norske Skog

Conversion projects during ongoing operations always present a major organizational challenge in addition to the technical ones. Under the sign of the pandemic, the challenge was once again much higher this year.

Therefore, we are particularly pleased that we were able to successfully complete the upgrading of the fluidized bed plant at Norske Skog in Bruck, a project from our Energy & Environment business area, on schedule despite the more difficult conditions.

The project started in February 2020 and ramp-up and commissioning occurred in November 2020. In December, the “As Built” documentation was handed over.

Prior to the project, a concept was developed to make the 25-year-old fluidized bed furnace fit for the next few years. The defined goal was, above all, reliable compliance with the legally tightened emission limits.

After our calculations we came to the conclusion to retrofit a SNCR system and a flue gas recirculation system with air preheating, as well as to modernize the fuel conveying system in order to massively reduce the emission levels. In the process, the fuel input was also converted from spreader feeding to feeding by means of a chute.

Since the plans were not available digitally, the boiler house and all relevant areas were captured in a point cloud with a 3D scanner. This was the basis for planning all further steps. Due to our extensive experience in the field of energy and process engineering, it was possible to plan and also implement the project within this short time. The total construction phase lasted only 6 weeks. The boiler shutdown was limited to a maximum of two weeks.

As with every project, there were one or two unplanned challenges, which we were able to overcome thanks to solid project planning and a great deal of personal commitment on the part of the highly motivated project team.

The excellent and constructive cooperation with our client must also be mentioned. After this intensive and busy period, we are happy to hand over to our customer a plant that meets the project goals and also gives the plant operators, after our training and the first practical experience, a safe and good feeling.

Werner Wipp, Project Manager

Increase in green electricity production

The Welsberg Niederdorf district heating plant cooperative was founded in 2001 in Welsberg in Alta Pusteria (South Tyrol) and has since been supplying the two communities with environmentally friendly district heating. After the analysis of the current situation during a plant visit with inspection, VOIGT+WIPP Engineers carried out optimizations to increase the production of green electricity.