The bad point control is an intelligent solution package for biomass CHP plants to operate district heat pumps in the optimal efficiency field while minimizing grid losses and electricity costs. Every heat customer in a district heating network requires a pressure difference between the flow and the return at its transfer point to the district heating network in order to ensure a sufficient supply of heat. The pressure difference is guaranteed by the pumps of the district heating network.

The control of the speed of these pumps can be different. Even though speed control today is practically always via frequency inverters, this does not automatically mean that maximum energy efficiency is guaranteed.

Classic variant

Simple, but not very efficient is the control to the differential pressure in the boiler house. The differential pressure can still be varied on a sliding basis according to flow rate or power reduction. It is preferable to calculate the required differential pressure from the pipe network characteristic curve of the district heating network and to transfer this setpoint to the controller for the network pumps. Nevertheless, there is also a risk of under-supply here, which is why a safety factor must be included, which in turn leads to increased pump power consumption.

Effizienteste Variante

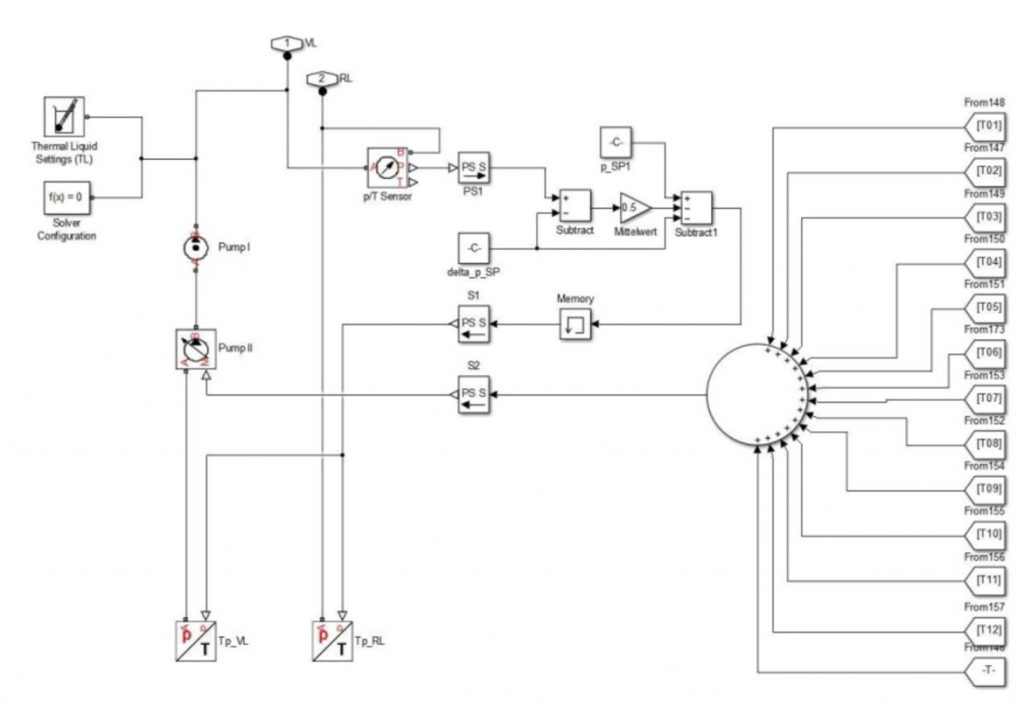

In order to always operate the network pumps at the optimum efficiency level between guaranteed heat supply and maximum energy efficiency, it is necessary to use all available information from the district heating network and the pumps. Based on the two variants above, the efficiency map of the pumps in use is also stored as a model. This adds an essential function to the controller, enabling intelligent pump management in addition to bad point control on pressure differential.

The VOIGT+WIPP Engineers Solution

This functionality is integrated in our BCS (Biomass Control Solution) Suite in the modules BCS-FWM (district heating management) and BCS-SPR (bad point control) in perfect interaction. This guarantees maximum efficiency in the heat supply, which also includes the minimum heat loss of the pipeline. The so-called “network losses”, as only as much water as necessary is pumped through the district heating network.

This system can also be ideally applied to large district heating networks with several pumping stations, as these can communicate with each other and thus react simultaneously to pressure differences in the district heating network.

Simulation model for pump management and pipe network characteristic curve (modeling FWN)

Steps to the most efficient variant

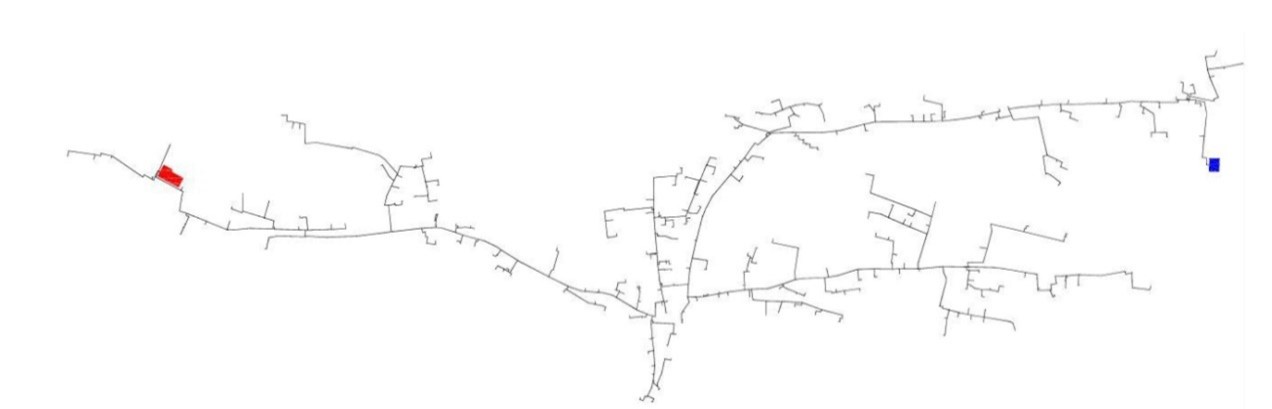

First, the current “bad points” in the district heating network must be identified. This can be done empirically or calculated from detailed piping diagrams. If changes to the district heating network are planned in the medium term, the bad points may be shifted. In this case, it makes sense to install several bad point measurements.

The differential pressure is transmitted to the heating plant via a GSM connection if no other transmission is possible or economical. Due to the wireless transmission of the information, the bad point measurement can be offset with less effort. This advantage becomes important in district heating networks that are continuously extended or modified by ring connections. In order to be informed about the current status of the bad points and the pump condition, this information is made available to the user via a web-based visualization. If a signal failure occurs between the bad point and the heating plant, the system switches automatically and without jumps to a fallback solution on the PLC, which is directly responsible for the setpoint specification of the district heating pumps.

Advantages of the bad point control for plant operators

- The bad point and pump management modules can be implemented quickly and flexibly

- The number of bad points in the district heating network can be flexibly adjusted as required without the need to stop operations.

- Efficient operation can reduce the power consumption of the district heating network pumps by up to 15 % – while at the same time optimizing supply and failure safety and reducing heat losses.

Reference project Holzwärme Altenmarkt

VOIGT+WIPP was commissioned by Holzwärme Altenmarkt to carry out an energy check for production plants promoted by Umwelt Service Salzburg. In the course of this energy check, the district heating network and the control of the network pumps were analyzed.

„The power consumption of the mains pumps could be reduced and the plant operation could be improved considerably by the bad point control optimized by the company VOIGT+WIPP Engineers, in which the operation of the four mains pumps in the Altenmarkt CHP plant was optimized by the integration of 3 redundant bad points. Through the cooperation with VOIGT+WIPP, we feel well equipped to master the future challenges for a technically as well as economically optimal generation and distribution of environmentally friendly heat for our customers in the best possible way.”

Ing. Günther Seifter, GF Holzwärme Altenmarkt GmbH

Everything from one source

In addition to special topics, such as bad point control, we are also experts in higher-level control systems and have developed the BCS suite, a complete control technology solution package specifically for biomass cogeneration plants. This consists of various modules that are installed on existing systems.

The control system docks onto existing automation and safety processes without changing or influencing them. Such modern control algorithms avoid costly conversion work as well as associated plant shutdowns.